Example of DHA (NFPA 652)

Example of Dust Hazard Analysis of a powder handling industrial process

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. What is NFPA

652 ? |

| 2. An example of

DHA ? |

1. DHA (NFPA 652)

A Dust Hazard Analysis (DHA) is mandatory as per NFPA 652, this page aims at giving an example of a DHA that can be useful for factory operators having to carry out their own analysis. In this example, a pneumatic conveying line for flours is studied.

In US, a standard focusing

on combustible dust explosions has been issued by the NFPA : the

standard NFPA 652. This standard is mandatory and

especially requires the completion of a Dust Hazard Analysis

(DHA). The document, as of May 2020, is setting a deadline

to complete the DHA by 7th September 2020 and asks for a review

and an update every 5 years. Not having completed the DHA properly

will result in OSHA citations.

2. An example of DHA

For this example, we consider a bakery which is having a small industrial process to produce biscuits. The 1st step of this process is to discharge bags of flours into the process and transport the wheat flour to a silo from where it will be dosed to the rest of the process. A complete analysis, beyond the silo, must of course be done by the plant owner but for this example we will stop at this 1st process part, that sometimes we can also call node : tip the material, convey and store it.

As a reminder, a dust hazard analysis is carried out through the following steps. Those steps will be followed to study the example given.

General explanations about dust explosion and Dust Hazard Analysis are given in the page in addition to what is related to the example. For an easier comprehension, the actual elements of the DHA example are in boxes.

| The DHA analysis of the example is in boxes like this one |

Warning : the analysis below is only an example to illustrate a method, it may not be exhaustive and cannot be used as such to any case, readers must do their own study adapted to the particularities of their process.

2.1 Hazard identification : material properties

What are and where are the materials combustible or explosible ?

The 1st step of the DHA is to determine if there are combustible dusts in the process, and what are their properties.

| In this case, yes, flour is combustible, we must then look for its dust explosion properties. Wheat flour being quite common, it can be possible to find in the literature the explosion characteristics of this material. |

Note however that if the material is not well known or has some specific characteristics (very fine...), it will be required to carry out tests with specialized institutes in order to determine the explosion data.

| For wheat flour 405 used in the process of the company, the following values are found in the literature [IFA] |

Those data are the most basic set required to run a DHA, in certain cases it may be required to have additional data. Note that a database, financed by the European Union, is available on line with 7000+ substances tabulated on https://www.dguv.de/ifa/gestis/index-2.jsp, when using the database one will realize that many data may be available for an only substance, the user must therefore be very careful to the conditions on which the data have been obtained in order to select the ones closer to its application (the particle size is very important, along with humidity).

If there were other materials processed on the same line, the same kind of data should be found and tabulated for the analysis.

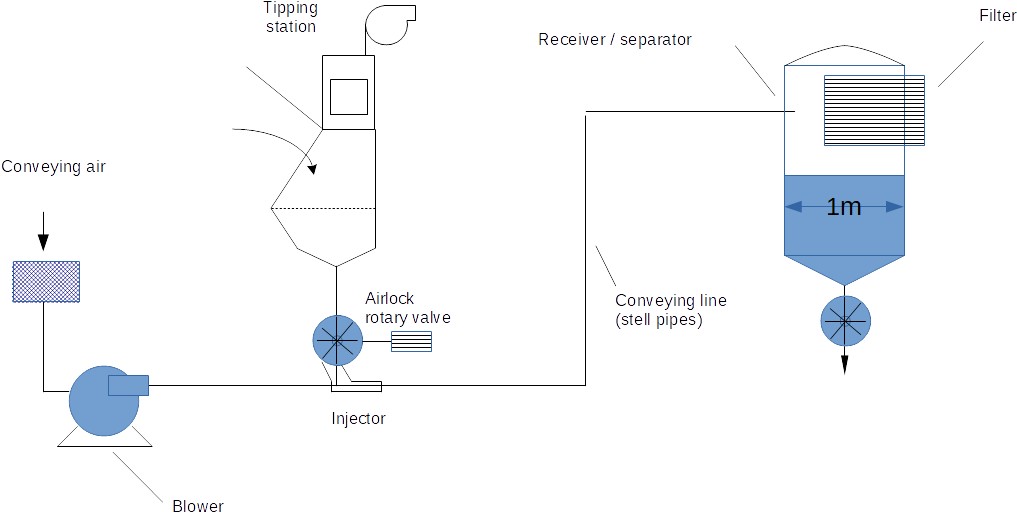

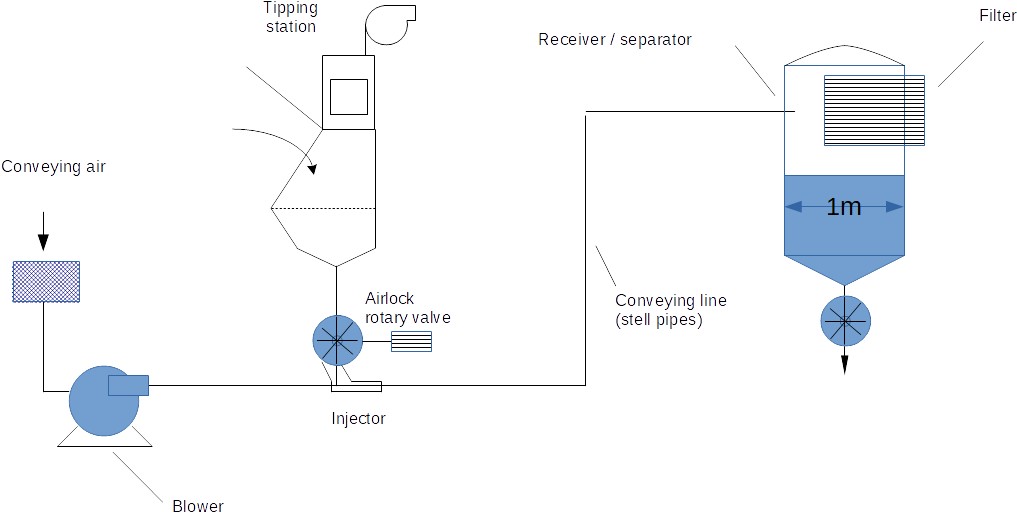

In addition to the material characteristics, Engineering documentation of the plant should be gathered and updated. Flowsheet, layout, equipment characteristiscs are required. In this example, the flowsheet below is considered.

|

The 1st step of the DHA is to map the production process in order to identify where are potential hazards related to dust fire and / or explosions. It is therefore advisable to perform a DHA with a multidisciplinary team which knows well the working environment and can provide relevant documentation (P&ID, equipment datasheet and drawings...) and which should include a person which has expertise in hazards related to combustible dusts.

The team performing the DHA must then start by gathering explosion data (MIE, MIT, Kst, Pmax...) on the dust handled in the factory, then must be listing the area where combustible dust is present. Once the factory is mapped, the actual hazard must be evaluated.

2.2 Analysis of the hazard

Where is dust present

?

Once the combustible data have been gathered, as well as the process data, it is thus necessary to combine both to check if there is actually a risk which means answering to those questions for each equipment :

- Is there a combustible dust in the area ?

- Can the dust be present in a dust cloud within the Minimum Explosive Concentration ? Or can dust accumulate in layers

- Is there an oxidant (typically oxygen)

- Is there an ignition source ? (if the dust is actually on the form of a deposit, the ignition source can simply be a source of heat)

To perform this part of the analysis, one must progress step by step through the process, typically considering the different equipment. In this example, we start by the tipping station, and ask the question if the there is a presence of dust in those area :

| Can dust be present in explosive concentration ? |

Inside equipment |

Outside equipment |

| Tipping station | Yes When unloading the bags of flour, a cloud dust creates at each tipping |

Yes In case of malfunction of the dust aspiration system or if the operator spills some product |

| Airlock rotary valve | Yes The airlock rotary valve operates with the powder inside |

Yes Dust may fall on the valve from the tipping station in case of leakage for instance |

| Pneumatic conveying piping | Yes During conveying, especially at start and stop of the conveying line, dust can be in explosive concentration in the pipe |

Yes There can be leakages at the coupling of the piping |

| Hopper | Yes When the product is conveyed a dust cloud forms in the hopper |

Yes Leakages can happen in manhole, connections... |

One may note that wherever there is powder / dust, the possibility to have the dust in suspension in air in explosive concentration can rarely be excluded.

Note as well that the potential risky area outside of the equipment can be limited to the area (typically 1-2 m) around the potential emission of dust.

Are there ignition sources ?

Now that the areas where dust can be present have been identified, it is necessary to check if there is an ignition source in the area that could trigger an explosion. The following ignition sources must be considered :

- Electrostatics

- Accumulation of electrostatic electricity that can suddently discharge

- Electrical

- Sparks coming from electrical apparatus

- Mechanical

- Typically metal / metal contacts

- Source of heat

- From works (welding activities...)

- From equipment (motor at high temperature, hot bearing...)

Electrostatics

There are different sources of electrostatics discharge in a

powder handling process :

|

| Sparks | Brush discharge | Propagating brush discharge | Corona | Cone discharge | |

| Tipping station | Yes | No | No | No | No |

| Airlock Rotary Valve | Yes | No | No | No | No |

| Pneumatic conveying pipe | Yes | No | Yes | No | No |

| Hopper | Yes | No | No | No | Yes |

From this 1st analysis, the risk of sparks in between 2 isolated conductive materials is present for all the the equipment. Thus, all metallic part in contact with a cloud of powder, or that maybe (in the area identified outside the equipment for example) should be grounded. In the example, we carry out the risk assessment of an existing installation, the Engineers must then inspect the process, record any part that may not be grounded, and establish an action point to correct them. If the process were at design stage, the Engineers responsible for the design should foresee grounding points for all equipment.

Note that some some equipment need particular attention, it is the case of the filters at the tipping station and at the hopper / silo. The filter cages must be electrically connected to the filter support and the filter support grounded. Many accidents happened because the elements of a filter were not properly earthed.

| The team carrying out the dust explosion risk assessment of the pneumatic conveying system make a visit of the line and see that several grounding points are missing and some dust looks to have spilled around the tipping station, on the floor and the rotary valve located below. |

The next electrostatic hazard highlighted by the analysis is the risk of propagating brush discharge in the pneumatic conveying pipe. In our example, the pipe is made only of steel, there is no part made of insulating material such as a flexible that could cause this kind of discharge. However, for other systems if flexible are required, then the flexible must be designed to avoid accumulating charges, especially if the flexible has a conductive coil, it MUST be grounded.

The last potential risk is the cone discharge in the receiving hopper. In our example the diameter of the receiver is only 1 m, which is very low, it is therefore highly unlikely to have such cone discharge, all the more that the MIE of the wheat flour considered is quite high. However for other applications with different products or particle sizes a formula is available to calculate the cone discharge energy expected as a function of the diameter of the hopper.

Electrical

The electrical components that may be in contact with a dust cloud inside or outside - in the area where dust cloud can be present - should be designed to operate in this environment. Norms are actually determining the class of the electrical equipment.

In the example for an existing installation, the factory operator must check the actual marking of the electrical components in the zone where powder cloud can be present. If not compliant, actions must be taken. In the case of a design project, the right equipment class must be supplied.

| The team carrying out the dust explosion risk assessment of the pneumatic conveying system make a visit of the line and checks the electrical equipment in the area where dust is present, they see that the airlock rotary valve is an old model with a motor presenting no mark of dust explosion safety rating. It is just showing IP54. |

Mechanical

Some mechanical issues can create sparks or heat high enough to trigger an explosion. It is required to list and check especially the rotating parts that can come in contact with a dust cloud. In this example, there are 2 rotating equipment : the airlock rotary valve located below the tipping station and discharging the flour to the pneumatic conveying line, and the Roots blower which is supplying the air for the transport.

An airlock rotary valve can fail, leading to a metal metal contact en between the rotor and the stator. One rule of thumb, for steel, is that sparks will be created if the metal metal contact happen at a speed > 1 m/s. In the example, the factory operator must therefore calculate the maximum tip speed of the airlock rotary valve rotor, if it is less than 1 m/s, the risk is low.

| The particular valve in the example studied has a diameter 200 mm and rotates at 40 rpm, which gives a tip speed of 0.42 m/s, the operation is fine. |

At design stage, the diameter of the airlock rotary valve must be selected so that the capacity is reached while the tip speed of the valve is <1 m/s.

The rotors of the Roots blower are rotating very quickly, typically at 3000 rpm, thus any misalignement could create some metal metal contact and then sparks that could be sent in the conveying line. Experience shows that those sparks will often extinguish in the pipe in between the blower and the inlet of product but to remove this risk, a flame arrester (a kind of mesh) can be added at the outlet of the blower.

| In our example, the blower is equipped with such a device. |

Source of heat

Factory operators must evaluate if there is any source of heat in the area where the dust clouds can be present. It can be for example some workshops with cutting or welding activities nearby a tipping station. Or it can be maintenance works that are carried out on the process. Those works can be particularly hazardous thus the plant owner MUST implement a good housekeeping (make sure there is no deposit of dust anywhere in the plant) and a work permit with a fire permit to make sure no one can come and start welding / cutting around or on the equipment that are processing combustible powders.

| In the example, the factory operator is not carrying any fire work in the vicinity of the equipment considered and has put in place an efficient system of procedures and work permit to secure any intervention on site. The factory is also equipment with vacuum cleaners allowing to keep the area cleaned. |

Other possible sources of heat include overheating motors, or overheating mechanical parts such as bearings.

In the example, the motor of the airlock rotary valve must be rated to have a maximum temperature < 2/3*MIT=2/3*400=266c or SIT-75c=450-75-375c, which means the motors should not reach a temperature >266c.

It should also be the case of the bearings of the rotary valves which should also be flushed to make sure the product cannot ingress in the bearing, damage it and potentially catch fire if the bearing starts to overheat.

| In our example the motor is of a sufficient class as it cannot exceed 185c. |

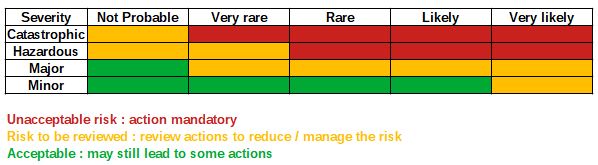

Classify the hazards

The different hazards presented by the installation have been reviewed, it is now required to classify them in order to see if specific measures are required to lower the risk. Note that different matrix exist to class the risks, the one below is just an example.

|

We continue with our example of pneumatic conveying line for floor. After analyzing the possible risks of explosion, the following remain :

|

| Not probable | Very rare | Rare | Likely | Very likely | |

| Catastrophic | |||||

| Hazardous | A | ||||

| Major | B | ||||

| Minor |

|

The team decides of the following ratings : Harardous / Likely -> unacceptable risk for the electrostatic spark risks, the activity considered involves indeed considerable amount of powder movement at tipping and in the pneumatic conveying line. This powder movement is charging the materials in contact, if some of those materials are isolated, spark discharge can happen leading to an explosion with the flour. At the tipping station or in the pneumatic conveying line the explosion consequence can be hazardous. For the motor of the airlock rotary valve, the risk assessed is lower, indeed the motor is still rated IP54 which gives a basic level of protection, the potential explosion would be out of the process equipement as well. After classifying the risks it is however required to reduce it, indeed, both risks are not deemed "acceptable" in the risk assessment matrix used. |

2.3 Management of the hazard

What are the safeguards to implement ?

The electrostatics spark risk can be managed by simply grounding all the equipment and ensuring that the grounding stays in place.

|

The factory in our example immediately sends the maintenance team to put back in place the grounding missing and record as an action to create a grounding checklist that will be used on a regular basis to make sure all grounding cable stay in place over time. This reduces the risk by lowering the probability of an explosion to very rare. For the airlock rotary valve motor, as the motor is getting old anyway and requires more maintenance, the factory decides to replace it. The actions to manage the risks are pending replacement to make sure the area remains clean, there is no dust spillage during tipping, and the motor connector box is well tight. On 2-3 months timeline the factory will replace the motor. |

In both cases, the strategy employed is to avoid the source of ignition. The risk matrix can then be updated with the new ratings once the actions have been performed.

| Not probable | Very rare | Rare | Likely | Very likely | |

| Catastrophic | |||||

| Hazardous | A |

||||

| Major | B |

||||

| Minor |

Note that in certain cases, the addition of mitigation measures such as explosion panel on the silo, quick acting valve in the pneumatic conveying line can be required.

The conclusions MUST be documented in the DHA and the factory MUST apply the conclusions. It is critical for safety that the risk be properly adressed, an action plan defined and timely executed. Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings