Dust explosion physical properties

Key physical characteristics to gather for assessing dust explosion risks and designing a safe process

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Summary of

inflammability and explosive characteristics of dust |

1. Summary table of inflammability and explosive characteristics of dust

One key point to remember when carrying out a dust explosion risk analysis is that as soon as a material can be oxidized, which means ignited, then it presents a risk of dust explosion. The risk of explosion and its consequences are then assessed thanks to the physical characteristics of the powder studied.

It is necessary to gather those physical data through experiments which should be carried out by reputable safety institutes. These data should be part of the MSDS of products, but are sometimes missing, incomplete or not very reliable prompting the need for new tests.

Table 1 : Dust explosion properties

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

------------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

| Property | Definition |

|---|---|

| Minimum

Inition Energy MIE (mJ) |

This data is very important for dust explosion risks analysis, it will show how easy a dust cloud can be ignited The MIE is equal to the minimal energy needed to be brought by a spark to a dust cloud of a given concentration in order to ignite it. Values are in between 1 and 1000 mJ. The closer the value is of 1 mJ, the easier the dust cloud can explode, which leads to specific process designs. |

| Minimal

Ignition temperature MIT (°c) |

If a dust cloud enters in contact with a hot surface, it may explode. The Minimum Ignition Temperature is the minimum temperature for which a hot surface will ignite a dust cloud MIT of 200-300°c are quite common. The lower the temperature, the higher will have to be the precautions to avoid hot surfaces within the process or within the process area. Motors for example should be a particular area of care. |

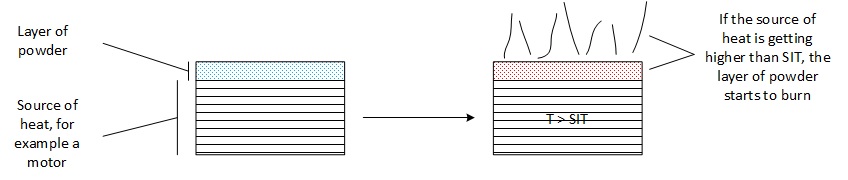

Figure 1 : physical meaning of SIT

| Self

Ignition temperature SIT (5 mm) (°c) |

When powder forms a deposits over a hot surface, it can start to smoulder. The SIT measures the minimum temperature of the surface necessary, for a layer of 5 mm, to start igniting the powder. This can be particularly hazardous as the powder burning can start a fire or trigger an explosion if it enters in contact with a dust cloud. |

| Powder electrical

resistivity (Ω.m) |

The electrical resistivity of the material will allow to assess how easy it can build up electrostatic charges. If the material is conductive those charges will dissipate easily, but if the material has a high resistivity, the build up can be consequent. The resistivity is playing a role in cone discharges explosion which can typically happen in silos after filling. |

| Minimum

Explosive Concentration (kg/m3) |

In order to be able to trigger the explosion of a dust cloud, the concentration of powder in suspension in air must be sufficient. This minimum concentration is called the minimum explosive concentration. It is actually most of the time low, in the order of 0.02 - 0.04 kg/m3, varying according to the product. Even if this concentration appears low, in reality, a dust cloud with such concentration is visually very dense, it is very difficult to see 1-2 m further with such a concentration.

|

Figure 2 : pressure profile of a

dust explosion

| Maximum

pressure of an explosion Pmax (bar) |

When an explosion occurs in a confined environment, it will lead to an expansion of the gas due to combustion and heating and therefore to an increase of temperature. Depending on the dust material, the maximum pressure changes. Pmax characterises the max explosion pressure for a given powder. This value is used for sizing explosion mitigation systems. The maximum pressure is usually in the range 4-10 bars but it should be defined for every material. |

| Explosion

constant Kst or Kmax (bar.m/s) |

The pressure increase to Pmax can develop more or less quickly depending on the material. The pressure variation can be described thanks to an explosion constant Kst (also called Kmax depending on the country). The higher Kst, the quicker the explosion will develop and pressure increase. Kst is necessary to size explosion mitigation equipments like explosion panels so that they can act quick enough before the pressure approaches Pmax. Powders can be ranked in explosion classes according to Kst : St1 : 0 < Kst < 200 St2 : 200 < Kst < 300 St3 : 300 < Kst < 600 |