Self Ignition Temperature (SIT) of dust layers

Physical meaning and use in risk assessment of powder minimum ignition temperature of dust layers SIT

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Definition of

SIT |

| 2. Determination

of SIT |

| 3. Typical range |

| 4. Use in risk assessment |

| 5. SIT of common dusts |

1. Definition of SIT

What self ignition temperature of dust means ?

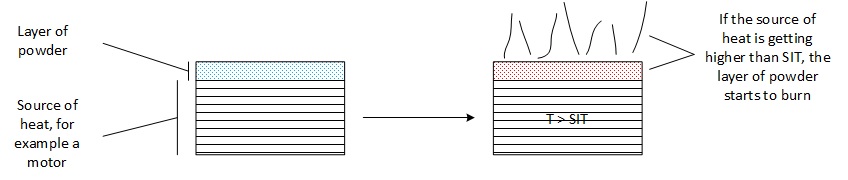

When a powder deposit covers a source of heat, it can lead to self ignition of the dust layer which starts to smoulder. The minimum temperature required to self ignite a dust layer is called self ignition temperature SIT or smouldering temperature. As this temperature is varying with the layer height, it is necessary to precise it : 5 mm is a quite general value.

Figure 1 : physical meaning of SIT

2. Experimental determination of SIT

How to calculate the Self Ignition Temperature of a powder ?

The SIT is measured experimentally. The experiment consists in covering a hot plate in a oven with a dust layer, then heating up the plate observing if the dust starts to smoulder (observation of glowing, flame, or strong increase in powder temperature) [Polka]. It must be noted that the SIT is dependent on the dust layer height. Increasing the dust layer height can decrease the SIT, it is thus very important to always precise in which conditions the self ignition temperature has been measured. A 5 mm height is common and represents quite well what could happen in dusty environment, not well cleaned, when powder is depositing over time.

The SIT is the smallest temperature of the oven observed that ignites the tested dust layer.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

---------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

To be representative, such experiences must be carried out following a clear protocol (example : ASTM E2021 in US, EN 50281-2-1 in Europe). The test machine mentioned in the norm is also important as values may be slightly different from one apparatus to another.

Those protocols should not be confused with the minimum ignition temperature of dust clouds which corresponds to other conditions and physical meanings.

3. SIT typical range

What are the typical values of SIT ?

SIT values are generally in between 250 and 450 degrees celsius, of course dependent of the nature of the material, and typically lower than MIT.

Each processor must carry out a dust explosion risk analysis in order to assess the risk related to a specific material in a specific process and take necessary precaution and mitigation measures.

4. Use in risk assessment

At what temperature a dust layer ignites ?

During a DHA (Dust Hazard Analysis) in US or ATEX risk assessment in Europe, the SIT must be compared to the maximum temperatures that can be observed in a process. This can be within the process or outside (motors for example). The process plant operators must make sure that dust is not covering hot spots in layers. At design stage, the SIT of the dusts involved in the process can be used to specify equipment and make sure by design that temperature cannot reach the SIT of any component of the process. It also emphasizes the need to have a perfect housekeeping when handling powders : no dust layer in the environment surrounding the process is acceptable as it could cover some equipment generating heat and therefore trigger a fire if the temperature exceeds the SIT.

The maximum admissible temperatures that can be put in contact with a powder layer is given as SIT - 75 K.

Tmax = SIT - 75K [Polka]

5. SIT of common dusts

What is the Self Ignition Temperature of rice, flour, wood... ?

Please find below some SIT data given in the literature for 5 mm layers. WARNING : these are general values given without guarantee, a risk assessment and design must ALWAYS refer to the MSDS of the ACTUAL product used for tests carried out specifically on the ACTUAL material by a reputable institute.

Table 1 : Minimum Ignition Energy SIT 5 mm of common materials

| Material | SIT °c 5 mm layers |

|---|---|

| Aluminium |

410 [Laurent] |

| Barley |

> 400 [Polka] |

| Beech |

320 [Polka] |

| Buckwheat |

320 [Polka] |

| Carrots dried |

300 [Polka] |

| Cereals |

300 [Laurent] |

| Coal |

250 [Laurent] |

| Cornflakes | 420 [Polka] |

| Epoxy powder |

melting [Laurent] |

| Hop | 290 [Polka] |

| Lemon balm | 290 [Polka] |

| Malt | 290 [Polka] |

| Milk powder |

340 [Laurent] |

| Nettle |

290 [Polka] |

| Oatmeal |

> 400 [Polka] |

| Polyethylene | melting [Laurent] |

| Rice flakes | > 400 [Polka] |

| Semolina | > 400 [Polka] |

| Senna fruit | 300 [Polka] |

| Starch |

345 [Laurent] > 400 for corn starch [Polka] |

| Sugar | 480 [Laurent] |

| Sulfur | 280 [Laurent] |

| Sunflower hulls | 290 [Polka] |

| Valerian | 280 [Polka] |

| Wheat Flour | 420 [Polka] |

| Wood flour |

340 [Laurent]

|

Sources

# [Laurent] Securite des procedes chimiques, Andre Laurent, Tec et Doc, 2003, page 237

# [Polka] Experimental analysis of minimal ignition temperatures of a dust layer and clouds on a heated surface of selected flammable dusts, Polka et al., Procedia Engineering 45, 414-423, 2012,