Measuring Degree of Mixing

(How to "Calculate Homogeneity")

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Industrial Question |

| 2. Definition of homogeneity for a particular process |

| 3. Defining the scale of scrutiny |

| 4. Choosing a tracer |

| 5. Defining the procedure to take samples |

| 6. Calculating CV homogeneity |

| 7. Is mixing ok ? Confidence intervals |

1. Industrial questions answered here

Is the powder mix homogeneous ? How to know if the mix is homogeneous ? What is meant by homogeneity of powdered sample ? How to check the homogeneity of a powder mixture ? ...

2. Definition of homogeneity for a particular process

Is the powder mix homogenous ?

It must be clear that the 1st step is to define for the application considered what means "homogeneous" and what means "non homogeneous". Almost all powder mixtures will have a degree of inhomogeneity. The 1st thing to do is to determine the tolerances which are exclusively dependent on the application for which the mixture is intended. Tolerances can be defined internally, or externally by a regulation or a customer.

Example 1 : The mixture is used internally for an other unit operation within the same factory : specifications are defined within the company, and maybe are quite large in order to ensure a smooth operation.

Example 2 : The mixture is sold directly, an infant formula for example, specifications are regulated by law, and can be very narrow

3. Defining the scale of scrutiny

What is the scale of scrutiny ?

Declaring a powder mix "homogeneous" means nothing if the sampling size from which the components will be analyzed has not been defined. The larger the sample size, the higher will be the chances of concluding that the powder mixture is homogeneous. Contrary, when reducing the sampling size, the variability of composition will go up and higher will be the chances of concluding that the mix is not homogeneous.

The sampling size, or scale of scrutiny, must always be defined according to the use that will be made of the mixture. For example, for a food product, the sampling size is the serving size. It would make no sense to sample a quantity that the customer will never use for preparing his food : either too small or too big. For this particular example, not choosing the right sampling value could have catastrophic consequences for a company whose products would be sampled by a government agency and found not compliant (company QA found the mix homogeneous but using a sampling size much larger than the serving size used by the consumer and as a consequence the government). For pharmaceuticals products, the sampling size will have to be in line with the dose to be contained in a capsule for example.

Top

5 Most Popular

1. Avoid and solve

pipe blockages in pneumatic conveying

2. Mass flow silos

3.

Dilute phase pneumatic conveying design and calculation

4. IBC bin mixing

equipments

5. Silo design guide

--------------

--------------

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer capacity

optimization

4. Batch /

continuous mixing comparison

5. Improve energy efficiency

of your process

4. Choosing a Tracer

What should be analyzed ?

Sampling will be of no utility if there is no way to make a distinction in between each sample. This distinction can be done thanks to a particular component of the mixture that will be a tracer.

The tracer needs to be chosen carefully since he will represent the behavior of other components in the mix.

A tracer is not a major ingredient (exception : if there are only major components in the mixture)

A tracer is usually chosen among small / minor ingredients which are often of interest in the mix. It will represent their behavior.

A tracer should have the particularity to be easily analyzed. It is better that the tracer is part of the mix formula, but it can also be added on purpose for a mixer validation exercise (example : salt addition).

Note that in certain cases, measuring a physical properties, for instance the particle size distribution, can be a way to characterize the homogeneity.

5. Defining the procedure to take samples

How to check the homogeneity of a powder mixture ?

Knowing which sampling size makes sense is a 1st step, but not sufficient. The way to take samples will be as critical.

For example, imagine a batch mixer, containing powder at the end of a mixing cycle. It would make no sense to take every samples only on the left of the mixer. Or only in the middle, or only on the right... The samples must be taken in order to represent the WHOLE mix, not only one part.

For this, different methods are possible :

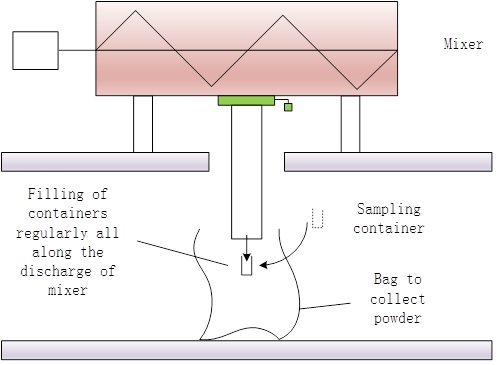

- The best one will be to discharge the content of the mixer and take samples at regular interval on the FREE FLOWING powder, from the VERY BEGINNING to the VERY END of the flow. This way, we ensure that no powder area in the mix was left untouched (figure 1)

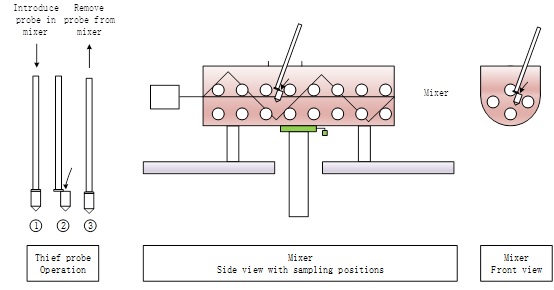

- If not possible, a sampling in the mixer will be necessary. For this, a sampling tool must be used and a sampling plan must be defined in order to make sure that no area of the mixer remain not sampled. This method is particularly difficult since it may not be possible to reach with ease every point of the mixer, and the sampling tool may induced a sampling bias on the results (figure 2).

It is recommended to take more than 30 samples in order to have statistically representative results

Figure 1 : Sampling on free flowing powder

Figure 2 : Sampling in mixer with thief probe

6. Calculation of CV homogeneity

How to characterize the uniformity of a powder mixture ?

After sampling, the samples taken are analyzed regarding the presence of the tracer. Then results are recorded and statistics can be performed.

The mixture, regarding the tracer, will be defined according to the mean concentration of the tracer and to the standard deviation of the tracer concentration. Mean and standard deviation will be used to calculate the relative standard deviation of the mix, that will be the value assimilated to "homogeneity".

Equation 1 : Relative Standard Deviation of the mixture

S is the samples standard deviation, it is not the actual standard deviation since only an estimation can be given from the samples. μ is the arithmetical average of the samples concentration, thus as well calculated from the samples.

This value is often expressed in % and called also the coefficient of variation

Equation 2 : Coefficient of variation of the mixture

The value obtained is then compared to the specification.

WARNING : the CV that will be obtained has actually several components, and some of these components need to be calculated in order to estimate the actual homogeneity variance.

The sample variance is calculated thanks to :

S2=Smix2+Sanalytical2+(Ssampling2)

The variability due to sampling is very difficult to determine, thus, in practice, it will be neglected. However, for this assumption to be true it is critical to sample the mix following the methods explained above, and preferably on the free flowing powder.

The variability due to analysis can either be known, if experiments have been done before, or can be determined for the particular homogeneity validation by doubling the measurement on the same sample.

Smix can then be calculated. Then CVmix(%)

7. Is the mix ok ? Confidence intervals

Is the homogeneity of your dry mix acceptable ?

WARNING : Once CVmix(%) calculated, it is not sufficient to compare it to the specificationb CVspec, which is the target CV. Indeed, the variance calculated is NOT a true variance but is estimated on the sampling. This estimation must be taken into account by calculating a confidence interval, generally at 95%, which corresponds to 2 sigma on each side of the mean.

The specification can then be compared to the confidence interval :

- If the CVspec > upper border of the confidence interval : the mixing is successful, the mix is significantly better than the specification

- If CVspec is in the confidence interval : the mixing may be successful, but it is also possible that the actual CVmix is > CVspec

- If CVspec is < lower border of the confidence interval : the mixing homogeneity achieved is not good enough for the application.

- Accept the mix

- Reject the mix and look for root causes (mixer speed, filling rate of mixer...)

Sources

[1] Perry's Chemical Engineer's Handbook

Article

: Is The Homogeneity Of Your Dry Mix Acceptable ?, Thomas

Lamotte, Chemical Processing Magazine, 2018