Mixer sampling

Why to take samples from a dry mixer ?

How to take samples from a dry mixer ?

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Definition |

| 2. Why to take

samples from a dry mixer ? |

| 3. How to take samples from a dry

mixer ? |

| 4. Sampling tools |

1. Definition

Sampling consists in taking a small part of the mixture in order to perform further tests. Generally, several samples have to be taken from a mix to come to reliable conclusions, especially when assessing the degree of mixing, or homogeneity, of a mixture. This page is focusing on the different methods available for sampling. The mix is assumed to be non hazardous.2. Why taking samples from a dry mixer ?

For industrials, it is key to be able to assess if the mixing process is reaching the desired level of homogeneity. Indeed there is naturally in dry mixes a certain degree of in-homogeneity, what is at stake being to minimize variations within a big batch.

To assess this degree of mixing and compare it to target, it is necessary to sample the mixture. It is particularly important when setting the mixing parameters (mixer speed, mixing time) for a new installation, or after having made some changes in the process, where many samples need to be drawn from the mixer in order to calculate a coefficient of variation. But it is also required in regular operation, to make sure that the process is under control : usually 1 sample is taken by batch or every x batches and checked vs reference.

3. How to take samples from a dry-mixer ?

The Engineer validating or optimizing a mixing operation has, for a batch mixer, the choice to take samples either :

- In the free flowing material, at the discharge of the mixer

- Directly in the mixer

- In a container (bin, Big Bag...) collecting the material from the mixer

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

Not all sampling methods are equivalent ! Indeed, each method is introducing a sampling bias more or less important that will impact the results of the mixing validation. It is generally understood that the best way is to sample the free flowing material right at the discharge of the mixer... although it is not always possible. Sampling in the mixer, and finally in a container after discharge will generate more sampling bias but are often more practical and can be chosen when the homogeneity requirements are not too high.

Note that for a continuous mixer, the sampling must be done on the material free flowing out of the mixer. It is generally easier than for a batch mixer as the flow rate is controlled and the access is normally better by design.

3.1 Sampling in the free flowing material

Sampling the mixture during its discharge presents the advantage, if the sampling is well executed, to be able to access the totality of the batch.

If sampling in the mixer presents the risk to omit an area which may not have been mixed properly, it is in principle possible to access all the mix when it is discharged.

The samples should be taken at regular interval all along the discharge (important not to forget the start and end of the discharge which may be inhomogeneous because of some dead volumes in the mixer). The sampling system should be able to cut the flow of product so that it is an entire slice of product that it is collected. If the sample is too large, it should be devided in a special sample divider in order to minimize the errors due to re-sampling.

3.2 Sampling in the mixer or in a container

To have a sampling as efficient as possible, it is necessary to have a tool allowing to reach deep in the mixture, the most common being a thief probe, in an attempt to cover all area of the mix. Such sampling must therefore be well prepared by creating a sampling map, representing the mixer or the container in 3D and showing where to sample the product.

Figure 1 : Thief probe

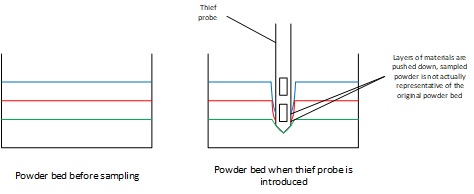

This methodology is very sensitive to sampling mistakes, if an area remote from the access door of the mixer is not exactly sampled where it should be, or if the sampling tool fills with product right at the moment it penetrates in the mix. It may also create some segregation around the sampling tool by pushing down the top layers and lead to sampling more of 1 component rather than another.

Figure 2 : Thief probe impact on powder bed and sample representativity

3.3 Automatic sampling

Considering this time a routine sampling, and not a full

homogeneity study, manufacturers have usually in range automatic

samplers that can be installed directly on a mixer, a discharge

chute or a hopper. Those sampler position in the process should be

studied carefully in order to minimize the sampling bias, but they

are usually sufficient to detect a very big variation in the

process : for example the absence of dosing of an ingredient, the

absence of mixing...etc...

4. Sampling tools

There are different designs available to perform sampling. This

ranges from very basic (spoon like) which will provide a sample, a

results, but probably with a large sampling mistakes, to more

developed designs. A study has been published by Rutgers

university and can be used to guide the choice for sampling tools

aiming at taking product directly in a mixer or a container.