Dust explosion protection : equipment venting

How to protect an installation against dust explosion ?

Solutions available to release the pressure in an equipment in case of dust explosion

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction :

What kind of vents are available for dust explosion

protection ? |

| 2. Explosion vents

: panels and bursting discs |

| 3. Flame quench : flameless venting |

Dust explosion venting is the last resort to safeguard people and equipment in case of dust explosion : this page reviews solutions that can be applied to safely vent an explosion such as explosion panels, bursting discs, flame quench...

1. Introduction

What equipment to install to protect against an explosion of dust ?

When studying how a dust explosion unfolds, one can see that the pressure is increasing slightly at the beginning and then very steeply, with an increase of pressure over time equal to Kst, into finally reach a maximum pressure Pmax. If nothing is done, the explosion will destroy the process equipment and injure or kill people working around.

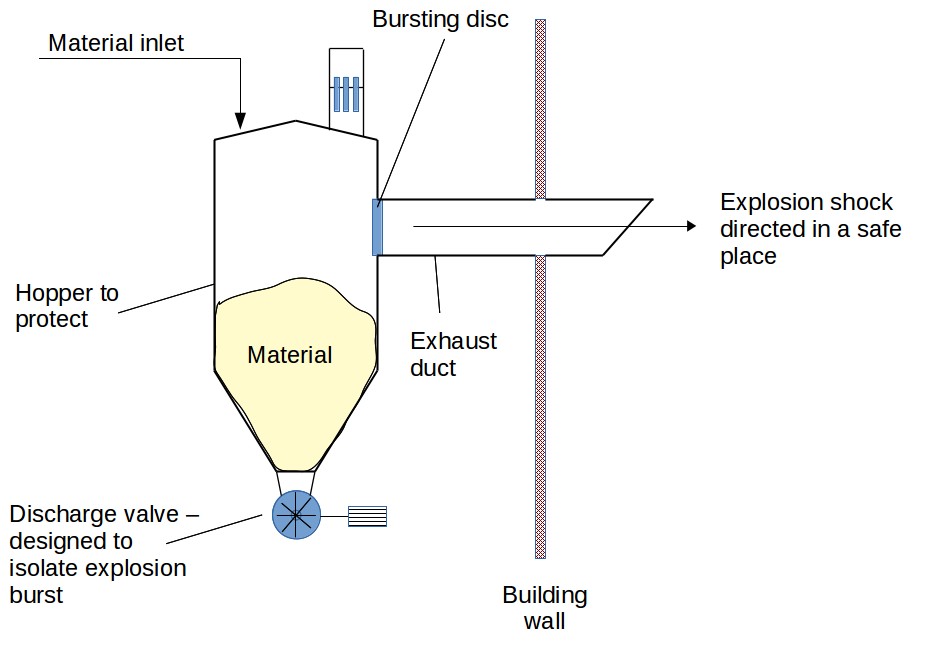

If a dust explosion risk analysis, like those done during DHA, DSEAR, or ATEX analysis, shows that the possibility of an explosion cannot be prevented, then one of the strategies to protect against the explosion is to vent the process equipment as soon as the pressure starts to increase. This way, the pressure inside the equipment stays within the design limit and the pressure shock and flames are vented in a safe area.

The venting, depending on the size of the equipment, can be done thanks to a bursting disc or an explosion door.

2. Explosion vents : panels, bursting disc

How to vent an explosion ?

The most common type of explosion venting is to cover an opening in a hopper or silo with a pre-cut membrane, typically in steel. The membrane is designed to withstand the normal process conditions, in terms of vacuum or pressure, but to open if the pressure reaches a certain level, which would be the sign of an explosion. Such vents are grouped in the generic term "explosion vents" but are sometimes called explosion panels if they have a rectangular shape or bursting disc in case of circular shape.

The design of such venting panels must follow some norms in order to be set properly in terms of opening pressure and size (area). This type of design must be carried out by trained consultants.

The panel must be equipped with a sensor that will detect its opening, the automation system must then shutdown the process as it means that an explosion may have happened (bursting disc are fragile and may open without an explosion if not installed properly for example). The panel must be positioned in an area where it is safe to vent, typically where nobody is present during production. If not possible, in a building for example, a venting duct can be installed, but it should be considered in the design.

Note that for big silos, it may be possible to install explosion doors, or flaps. These are not based on a membrane but rather a hinged flap that will open in case of an explosion, then re-close.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

3. Flame quench - Flameless venting

What is a flame quench ?

It may be necessary to vent the explosion in a building. This can happen if the route for an exhaust duct is too complicated or if for hygienic reasons it is not recommended. Just venting the explosion inside a building would have catastrophic consequences as the pressure shock could damage the building, other equipment, or worse trigger a secondary explosion by lifting dust in the production area that would be ignited by the primary explosion flames.

How works a flameless venting ?

In this case, one possibility is to install a flame quench, also called flame arrester or arrestor. It is a large device that will cover the explosion panel and will stop the propagation of flames. It is made of a stainless steel grid and filters that allow to stop flame and also reduce the pressure shock.

The design of a flame arrester must be done very carefully. This must be done by by the vendors which are specializing in this kind of equipment. The following input to the design must be considered in order to size the flame quench properly [PPI] :

- Particle size and morphology : different dusts, having different particle sizes, or which will melt during the explosion, will have different effect on the flame filter. If it is recognized that the dust risk to strongly clog the filter, it must be increased in size to avoid to have a too high pressure in the vessel. In case a vessel foreseen for one product is re-purposed, and that the product handle changes, the vendor of the flame quench must be consulted, as the properties of the dust may change which could impact the efficiency of the flame filter.

- Dust concentration : as for the previous point, the dust concentration will have a strong impact on the amount of particles that will go to the filter, be stopped, and then increase the pressure drop when an explosion happens.

- Vessel volume : larger vessels will tend to have more potential to generate a high load of particles going to the filter in the event of an explosion

- Vessel geometry : depending on where the explosion happens in the vessel, and where is located the flame arrester, the particle concentration to the flame arrester may change.

The installation of the flame quench requires some precautions :

- It should not be in a passing area where people are supposed to stand (Gas escaping the flame arrester will be hot, pressure wave), and should not be too close to the wall.

- If the flame arrester is under sized, unburnt particles may still escape during an explosion. To avoid a secondary explosion, a zone 22 should be declared within some distance of the flame quench.

Each manufacturer has some recommendations that it is necessary to follow.

This device must also be maintained, especially to make sure that the grid and filter do not get clogged over time. For this purpose, a cover supplied by the manufacturer can be installed.

Explosion vents needs must be defined thanks to a dust explosion risk analysis. Conclusions of the risks analysis must be implemented by the factory.