DHA Dust Hazard analysis -

ATEX Dust explosion risk assessment

How to do a Dust Hazard Analysis ?

Guideline to perform a dust explosion risk assessment of bulk solids handling process

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| What is a DHA

(dust hazard analysis) ? |

| 1. Step 1 Zoning :

probability of presence of a dust cloud |

| 2. Step 2 Ignition source : assess

the risk of ignition |

| 3. Step 3 Calculate the risk |

| 4. Step 4 Manage the risk and

take actions |

Dust explosions constitute the major safety risk for industries operating powder and bulk solids handling processes, but there are tools to assess the dangers caused by dust explosion and that help to put in place measures to avoid dust hazards. This page explains how dust explosion risks assessments are typically done.

What is a DHA (dust hazard analysis) ?

It is mandatory in many countries, and in many international companies, to carry out a dust explosion risk analysis of an industrial process. Dust explosions happen and are very destructive, avoiding or mitigating them is necessary to operate safely a process handling bulk solids.

The risk of dust explosion is the product of :

the

probability of presence of a dust cloud in explosive

concentration

x

the probability of presence of an ignition source susceptible to

ignite the powder

Higher probabilities may lead to specific measures to manage the risk.

In the US, NFPA norms, such as NFPA

652 define how to manage risks related to dust handling. This

applies to all process plants. The standard is defining how to

carry out a systematic analysis in order to identify the risks of

dust explosion and then define how to manage them. For

industrials, having such an analysis is mandatory and can be

asked by the authorities such as OSHA.

NFPA 652 is quite general and give

the basics common to all industries. Other NFPA standards that

could be relevant are :

NFPA 654 – manufacturing, processing, and handling—broadest

regulation and the base for the others

NFPA 61 – agricultural and food processing (organic dusts)

NFPA 484 – combustible metals

NFPA 655 – sulfur

NFPA 664 – wood processing and woodworking

NFPA 68 – deflagration venting

NFPA 69 – explosion prevention systems

In Europe, similar regulations have

been enforced since the 90s and take the name ATEX

(Atmosphere Explosive). A dust explosion analysis is also

required.

This page is mainly based on the

european ATEX regulation and follows the methodology advised by

this norm but most of the principles explained overlap with

the template of a DHA - Dust Hazard Analysis - which is

basically requiring to list which are the hazards (paragraph 3,

4), where they are located (paragraph 4) and how to mitigate them

(paragraph

5).

How to do a Dust Hazard Analysis : Step by Step guide

1. Step 1 Zoning : probability of presence of a dust cloud

A risk of explosion is present only where a fine powder cloud can be present. The 1st task is thus to assess where dust can be put in suspension in hazardous concentration. The probability of presence is then defined from zone 20 to 21 and 22. More information on the zoning and how to rank it is given here. In the US, the locations are classified in 3 categories :

- not a hazard

- might be a hazard

- deflagration hazard.

If there is a hazard, additional studies to determine the risk and

hazard management measures is required.

2. Step 2 Ignition source : assess the risk of ignition

For each area identified as an ATEX zone, thus where there is possibility to have a dust cloud, the next task is to define the risk of ignition source. It is a very detailed analysis that needs to go equipment by equipment, looking at its design and the possible malfunctions that could lead to ignition.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

The details of all possible ignition sources to consider can be found here.

It is advised to generate one analysis table for each source of ignition. For example, for mechanical sparks, the attention will be focused a lot on rotating equipment, if the rotating equipment is very slow as can be an airlock rotary valve, the risk of spark will be low or non existent. On the other hand, for a mill reaching 20-40 m/s in tip speed, the risk will be high that sparks happen in case of malfunction or presence of foreign bodies.

3. Step 3 Calculate the risk

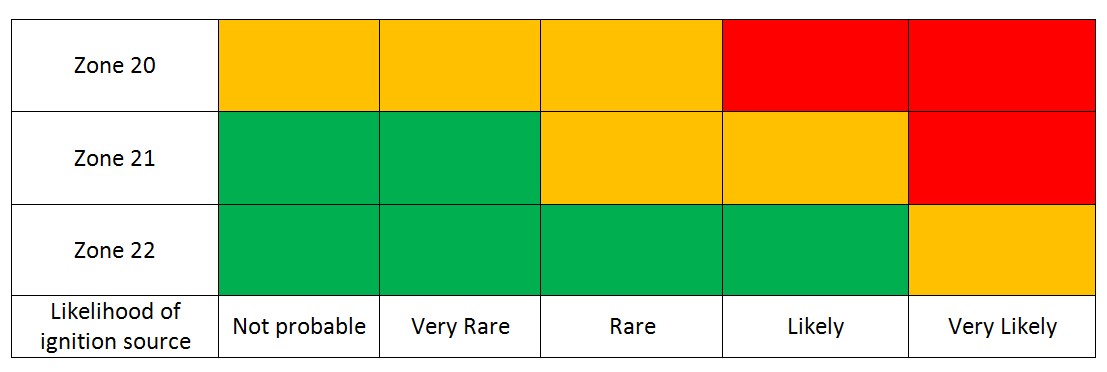

The combination of the zone classification and the probability of having an ignition source in this zone can then be represented on a table. The table helps to spot dangerous situations requiring actions.

Taking again the example of a milling system, the zoning inside the equipment will be 20, while the risk of ignition will be rare or likely depending on the design. It brings the combination to the top of the table, which points out that the risk is not acceptable as such and measures must be taken.

4. Step 4 Manage the risk and take actions

In case a risk requiring action is identified, the factory needs to put in place some measures to manage it and operate safely. This can be of different natures :

- Reduce the probability of dust cloud : for example if an equipment is opened or leaking creating a dust cloud outside, repairing it or changing the design can improve the zoning.

- Reduce the probability of ignition : coming back to the example above on a rotary equipment, if a screw is found to rotate too quick, it may be possible to run it slower without consequence for the process. If necessary, the equipment can be changed. For electrostatics for examples, some procedures can be put in place to make sure the whole installation is properly grounded.

- Put in place mitigation measures : if the risk of explosion cannot be controlled by prevention, it is necessary to foresee mitigation measures, like explosion vents, explosion isolation or explosion suppression. This is often the case for milling systems or some pneumatic conveying systems to large silos.

You can access here examples of dust hazards analysis :