Dust explosion vents : step by step sizing guide

Method to estimate the required size of explosion vents, explosion / burst panels, used to mitigate dust explosions

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction |

| 2. Pre-requisites

to the sizing of dust explosion vents |

| 3. Method limitations |

| 4. Calculation procedure step by

step |

| 5. Dust explosion vent ducts |

| 6. Other calculation methods |

Dust explosion vents are a crucial equipment to ensure the safety of a process handling combustible dusts. This page is explaining step by step how to estimate the size of dust explosion vent.

1. Introduction

It is mandatory for a factory operator to perform a dust explosion risk assessment and put in place all the measures required to prevent explosions. Sometimes however the residual risk is too high and explosion mitigation measures must be implemented such as explosion panels on hopper, silos, filters on some conveyors. This page is explaining how are built explosion panels and propose approximates methods to size them.

The methods presented here are not accurate, they are used only as illustration of the concepts guiding the design and as a 1st approximation for budgetting for instance but MUST NOT BE USED FOR DETAIL DESIGN. FOR ACTUAL IMPLEMENTATION ALWAYS CONTRACT A REPUTABLE COMPANY TO SIZE AND INSTALL THE PANEL.

2. Pre-requisites to the sizing of dust explosion vents

Knowing the dust explosion properties

In order to be able to size an explosion panel allowing to relieve the pressure of a dust explosion, it is necessary to know "how" the dust will explode, that is to say it is required to measure the dust explosion properties of a material. Especially, the following must be known :

Knowing the caracteristics of the vessel to protect

The sizing of the explosion panel will change according to the volume, shape and the design pressure of the vessel to protect. It is therefore required to gather the following :

- Maximum allowable working pressure

- Volume of the vessel

- Ratio length (height) over diameter : L/D

3. Method limitations

The method presented is only valid with the following assumptions :

- Volume in between 0.1 and 10000 m3

- Static activation pressure of the vent in between 0.1 and 1 bar g

- Reduced explosion pressure in between 0.1 and 2 bar g, and should be at least equal to the static activation pressure 2 times the vent burst pressure tolerance

- Pmax in between 5 and 10 bar if Kst is in between 10 and 300 bar.m.s-1

- Length/Diameter ration L/D in between 1 and 20 ; with vertical shaped hoppers (if the shape is horizontal, this method will not apply)

- Pressure at ignition < 110 kPa and oxygen concentration < 21%

4. Calculation procedure step by step

4.1 STEP 1 : gather dust explosion characteristic data and vessel construction data

As explained above

4.2 STEP 2 : define the ratio L/D according to the position of the vent

Considering a vertical cylindrical hopper, the ratio height over diameter L/D will depend on the position of the vent which typically can be either install on the top, or on the side. The "length" is then the maximum length that the flame, Leff, will have to travel in order to exit the vessel through the explosion vent.

In case a cone is present, the contribution of the cone to the flame effective length is considered to be 1/3 of the cone height [SHAPA 1].

The "diameter" is also actually an effective diameter that must be calculated thanks to the calculation of the effective volume.

Note that in some cases, the longest flame path can be from the top of the hopper to the bottom of the explosion panel. It can be the case for some filters.

4.3 STEP 3 : calculate the required vent area of the explosion panel

A = B*[1+C*log10(L/D)]

B = [3.264*10-5*Pmax*Kst*Pred-0.569+0.27*(Pstat-0.1)*Pred-0.5]*V0.753

C = [-4.305*log10(Pred)+0.758]

With :

A = required vent area in m2

V = actual volume of the vessel in m3

Kst = explosion pressure increase rate in bar.m/s

Pmax = maximum explosion pressure in bar

Pred = reduced explosion pressure in bar (it is the

target maximum pressure in the vessel reached after the explosion

vent has burst open)

Pstat = static opening pressure of explosion vent in bar

(it is the design static pressure at which the explosion vent will

open)

L/D = L/Deff = shape ratio of the vessel protected by the

explosion vent

[SHAPA 2] is mentioning that an efficiency must be taken into account to correct the calculated venting area. It is then critical to design the vent with the manufacturer which will then be able to determine the efficiency of the explosion vent. Such design should not be done alone by factory operators.

If the efficiency is, let's say 90%, then the actual area required will be A/0.9

4.4 Example of calculation of the size of a dust explosion vent

The hopper to protect is located at the end of a pneumatic conveying line. It is a conical hopper equipped with a filter and for which the factory has determined by its dust explosion risk analysis that it will have to be fitted with a side explosion panel. The factory would like to check the size of the panel required, to make sure it can install it, and then get an idea of the cost. This work is done during basic design and then the company plans to hire a specialized company to confirm during detail design.

The hopper has the following dimensions :

- D = 2 m diameter

- Cylindrical height Hshell = 3 m

- Position of vent must be above the level of product, it is 1 m from top of hopper, Hvent = 2 m

- Cone height hcone = 2.5 m

- Cone outlet diameter do = 0.25 m

STEP 1 : gather the dust explosion characteristics

The product being stored has the following characteristics :

- Kst = 150 bar.m/s

- Pmax = 8.5 bar

Considering the mechinal resistance of the hopper, the factory wishes that the vent opens at 0.2 bar g and the residual pressure Pred do not exceed 0.5 bar g.

STEP 2 : define the ration L/D

- Effective flame length Leff = 2.5/3+2 = 2.8 m (see case 2 of paragraph 4.2)

- The effective volume Veff = π.D2/4*Hvent +(2*π/3*(D2/4+(D/2*do/2)+do2/4)/3 = 7.08 m3

- The effective diameter is then Deff = 2*(Veff/Leff/π)0.5 = 1.78 m

- The ratio L/Deff = 2.8/1.78 = 1.58

The required vent size can then be calculated :

- V = 12.4 m3 (the top cover is considered flat here to simplify calculations)

- B =0.66

- C =2.05

- A = 0.94 m2

It is required to install a vent with a size >0.94 m2 to protect the hopper.

WARNING : the calculation above is

only for illustration on this website, it cannot be used for

detail design, any other use is at the own risk of the user.

Detail design must be done with a company specialized.

5. Dust explosion vent ducts

It is sometimes required to direct the explosion flame and pressure wave away from the equipment, outside a building for example. It is done through the implementation of a duct at the outlet of the explosion vent. The presence of the duct is an important design parameter as it will influence the actual reduced explosion pressure reached in the vessel protected. After calculating the required venting area through the method explained above, it is therefore required to correct the reduced explosion pressure due to the presence of a vent. If the reduced explosion pressure is too high, then the vent design must be adjusted.

In any case, the diameter of the duct must at least be equal to the diameter of the vent. [SHAPA 2] is mentioning that the duct should be straight.

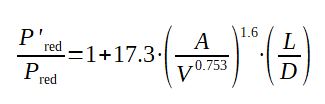

The reduced pressure in the presence of a vent can be calculated, for vessels of a maximum size of 100 m3 by the following formula [Laurent] :

P'red/Pred = 1+17.3*(A/V0.753)1.6(L/D)

With :

P'red = reduced pressure with a duct (bar g)

Pred = reduced pressure without duct (bar g)

L = length of the duct (m)

D = diameter of the duct

One important point to consider is for flameless venting (flame arrestors) : a study [Gregoire] showed that the formula above were not directly applicable for these kind of vents as the fluid dynamics are totally different due to the present of a filter. Those systems are presenting a lot of advantages but their sizing must definitively be given to their sole manufacturers, only entities with enough data to size these vent adequately.

6. Other calculation methods

The method given above is actually derived from an earlier method called "nomograph" method. It is a graphical method that was proposed as a german VDI norm from 1979 and revised several times then. This method was used as a basis of other norms in US, France...etc...

[Laurent] is reporting that the equations above can be slightly modified in order to take into considering the turbulence in the vessel at the moment of the explosion, which is a very important parameters influencing it.

A coefficient of turbulence τ is introduced, with τ that should be in between 0 and 3.5 :

The NFPA is recommending the following formula [Agarwal] :

Av = a.(V2/3).(Kst)b.(Pred)c

a = 5.71*10-4*exp(2*Pstat)

b = 0.978*exp(-0.105*Pstat)

c = -0.687*exp(0.0226*Pstat)

With

Av = Required venting area in m2

V = Empty vessel volume in m3

Kst = Dust explosion characteristic value in bar.m/s

Pred = Reduced pressure in barg (max pressure reached in

the vessel during a vented explosion), it should not exceed 2/3 of

the vessel burst pressure.

Pstat = Pressure at which the vent opens in barg, it is

>0.1 bar g (the equation above is not verified for lower

pressures) while a good practice is to set it 0.5 psi higher than

the operating pressure of the hopper.

The measures put in place to avoid ignition sources and the type of explosion mitigation chosen, must be described in the Dust explosion risk analysis (Dust Hazard Analysis) and the measures to put in place explained. Conclusions of the risks analysis must be implemented by the factory.

Source

[SHAPA 1] Sizing of explosion relief vents, SHAPA Technical

Bulletin 10

[Agarwal] Dust Explosions : Prevention and Protection, Chemical Engineering Magazine