Powder physical and flow properties

General physical and flow properties of powders and bulk solids

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Powder flow properties : Shear Cell Tester (Jenike Method) |

| 2. Intermediary Methods : powder cohesive index |

| 3. Shortcut Methods : angle of repose, Carr and Hausner Index |

| 4. Electrostatics |

What it is about

Understanding the properties of the powder is the 1st step to a good design, or efficient troubleshooting, of an industrial installation. Unfortunately, all interesting data are not always available to the Engineer. This section is focusing on the most important data. They are listed and described in the following table.

What are the properties of powders

Table 1 : Powder Properties

| Property | Unit | Interest | How to measure |

|---|---|---|---|

| Bulk density | kg/l | Sizing of vessels, mixers, bags, feeders... all

items that hold powder or dose powder Note : the bulk density can be referred as tapped or untapped (also called loose density). Untapped should be considered as long as the powder is aerated (in a receiver after a pneumatic transport for example) |

Bulk density can be measured by weighing a given volume of bulk solids. The sample can be tapped or not. |

| Apparent Particle density | kg/l | Particle density will be relevant when the movement of the solid must not anymore be considered as a mass, but as individual. It is the case for some technologies of pneumatic transport. | Apparent Particle density can be calculated from the skeletal density and the porosity of the particles |

| Skeletal density | kg/l | Used to calculate the apparent particle density | The skeletal density can be measured by gas pycnometry (example helium) |

| Cohesive strength | Cohesive strength will be used in silo / hopper design in order to calculate the proper outlet size | Shear cells (see explanations below) | |

| Wall friction | Degrees | The wall friction is used to calculate the angle of hopper cones, as well as the internal friction parameter | Shear cells (see explanations below) |

| Permeability | Permeability will give an indication of the capacity of the solids to retain air. It is a parameter used in calculating discharge rates and settling times | Advanced powder rheometer, fluidification | |

| Segregation tendency | Will give interesting information on the risks of segregation that can happen when handling a powder (segregation at discharge, difficulty to mix...) | Homogeneity tests | |

| Sliding at impact points | Will help to determine the angle of piping after a hopper, to let the powder slide (to a mixer, a bag filler...) | ||

| Particle friability | Is the particle fragile, can we anticipate particular measures to transport it, mix it | ||

| Particle Size Distribution (PSD) | A control of the PSD can be required for a specific final application or for controlling the input to further process steps. Measuring a PSD is particularly important for comminution / size reduction processes. | Measuring method can be more or less complex and precise. A simple way to proceed is to perform an sieving analysis, but it is quite rough. Automated method give a more pecise particle size distribution quite quickly ; a popular method is the laser light diffraction. | |

| Shape of particles | A control of the shape of the particles can be required for the needs of a specific final application. Knowing the share of the particles can also help anticipate mixing problems (interlocking shapes preventing a good mix) | Microscope, image analysis | |

| Hardness | Mohs index | Will help evaluate how abrasive the processing of the solids will be | Material is classified according to its capacity to be scratched by some reference materials |

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

The paragraphs below will describe the notion of powder flowability, which is actually covering different bulk solid properties :

- Cohesive strength

- Wall friction angle

It will also be explained how to practically determine those properties.

Some shortcut methods to anticipate flowability are also given at the end of the page.

The performance of an industrial process will be judged, among other parameters, according to its capacity to reach a nominal speed (expressed in terms of throughput, cycle time or number of batches / h). If a hopper which is supposed to deliver powder at a given rate cannot do it, be it placed at the beginning, middle, or end of the process, the whole installation "speed" will be affected. Being able to predict the solids flowability , out of a hopper for example, is therefore of critical importance for bulk solids handling.

What is powder flowability

The following notions, important to design properly hoppers and to promote solids flow, will be explained in this page

1. Jenike Method [Shear Cell Tester - What can we get from it ?]

Shear Cells

The Shear Tester or Shear Cell will allow to estimate very important powder rheology properties like the Cohesive strength and the wall friction which can in return be used to calculate hopper outlet diameters and angle of discharge.

2 shear tests need to be done in order to determine the properties :

- 1 test is to measure the angle of internal friction ; for getting this property, the test cell will measure the strength necessary to make the powder slide on ITSELF.

- On the other hand, the wall friction angle will be determined thanks to a cell that is measuring the strength necessary to make a sample of powder slide on a MATERIAL plate, the material being commonly the metal in which the silo will be built.

|

|

Figure 1 : Jenike cells

The test is performed after a pre-shear step which will give a certain density of powder prior to applying the normal stress and the shear. This pre-shearing can be varied which will give different results. Those different results will be used to draw different yield locus and subsequently calculate different properties of the powder (see below).

STEP 1 - Run the test

2 forces are applied to a sample of powder. One normal, which is set, and that is being gradually increased. And the second to the side (shear force). This 2nd force is measured and corresponds to the force to slide the sample of material.

Each couple (Normal stress ; Shear Stress) is recorded and then plotted. From this curve, different powder rheology characteristics can be calculated. The graph obtained, called wall yield locus is shown below (example - not an actual powder)

The following powder properties can be determined from the graph obtained (called "Yield Locus")

Table 2 : Shear cells output

| Shear Tester | Direct determination | Calculated |

|---|---|---|

| Shear cell measuring material / powder interaction | Wall friction angle Φ' | - |

| Shear cell measuring powder / powder interaction | Effective Angle of internal friction δ Static Angle of Internal friction Φ Major principal consolidation (or compaction) stress σ1 Cohesive strength fc (also called Unconfined Yield Stress UYS) |

Powder (or Material) Flow Function (by drawing the couples UYS and σ1 obtained at different pre-shear) |

STEP 2 - Draw Yield Locus

Powder - Powder interaction

For a given pre-constraint, draw the yield locus from the data obtained from the cell testing the interactions powder / powder

Figure 2 : data obtained from yield locus of powder - powder shear cell

Powder - Material interaction

Draw the yield locus from the data obtained from the cell testing the interactions powder / material

Figure 3 : data obtained from yield locus of powder - material shear cell

STEP 3 - Calculate the flow function

The yield locus is performed according to an initial consolidation state. It is possible to vary the initial consolidation state. Drawing the different yield locus, at different initial consolidation, will give the basis to determine the flow function of the powder. An illustrative example, with 3 yield locus is given below.

Figure 4 : Graphical determination of powder flow function

From the 3 different yield locus, 3 couples (Major consolidation stress sigma1 ; Cohesive strength fc) can be calculated.

A graph showing fc=f(sigma1) can then be drawn. This is the material flow function of the powder being tested (not to be confused with the flow factor ff). The flow function brings key information on the behaviour of the powder, in a more reliable way than shortcut methods like the angle of repose or some indexes.

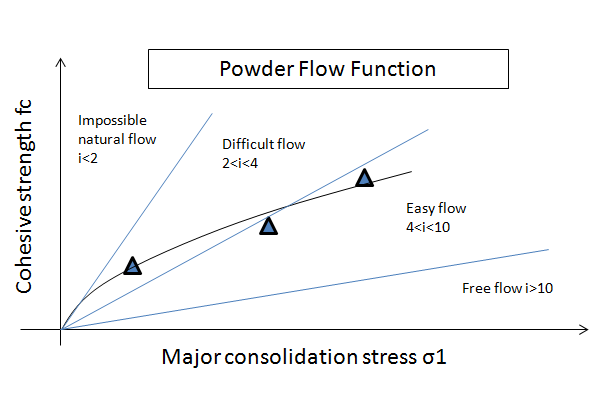

In the example, only 3 couples are considered, but more will be used to draw the actual flow function. The graph can be divided in different areas by straight lines passing by the origin and with the slope i=(σ1)/fc. The different values of i are giving information on the flowability, depending on the position of the flow function on the graph, its flowability can be determined.

Figure 5 : powder flow function and flowability of powder

Depending on the shape of the graph, we can determine if the powder is cohesive or not.

Figure 6 : Typical Material Flow Functions (MFF)

At the end of the testing with Jenike shear cells (or equivalent test equipment), the following powder rheology properties will have been determined :

- Angle of internal friction

- Powder (Material) Flow Function (MFF)

- Angle of wall friction

Note : it is then possible to determine how the powder will flow out of a given hopper (or design a hopper) by determining the flow function ff linked to a hopper design and plotting a line of slope 1/ff on the Material Flow Function MFF. Powder will flow if the line of slope 1/ff is above the MFF, if below, arches are expected to form and the flow to be difficult. More information can be found here on hopper design.

Figure 7 : Flow Function and Material Flow Functions to calculate Critical Applied Stress

2. Intermediary methods - Powder Cohesive Index

Some experimental methods have been developped to approximate the results obtained with the Jenike's method which is quite time consuming if specific equipment are not available.

A series of tests has been developed by Johanson. It allows to determine different indexes that can be linked to the key design parameters defined above.

Table 3 : list of simplified methods for flowability evaluation

| Method | Value obtained |

|---|---|

| Hang-up Indicizer | Arching Index AI (=critical outlet diameter) Rathole Index RI (=rathole diameter) |

| Hopper Indicizer | Hopper Index HI (=cone angle) Chute Index (=sliding at impact) |

| Flow Rate Indicizer | Flow Rate Index FRI (=max discharge throughput by gravity

- without discharging aid but with a totally NON aerated

powder) Unpacked density FDI and Packed density BDI (=loose and tapped density) |

To get these particular data, it is necessary to buy or have access to machine built by companies active in the field of Powder analysis.

3. Shortcut methods - Angle of repose, Carr and Hausnerr Index

A shear tester may not be available in factory day to day life, when a new bin needs to be calculated or the process needs to be troubleshooted. Other methods have been developed, quicker, to have an idea of the behavior of powder. The use of such shortcut method should be done with care, always considering that they will give an indication of the behavior of powder, but cannot be used for direct calculation

Table 4 : Calculated Index for assessment of flowability

| Method | Calculation | Interpretation |

|---|---|---|

| Carr Index | I=(tapped density - loose density)/(tapped density)*100 | I less than 15% : good flow I more than 25% : bad flow |

| Hausner Index | Hr=(tapped density)/(loose density) | Hr more than 1.4 : cohesive powder Hr less than 1.2 : free flow In between : intermediary behaviour |

| Angle of repose

method - powder flowing angle |

Poured angle of repose | angle less than 30 : good flow angle from 30 to 50 : difficult flow angle more than 50 : almost impossible flow |

A potential use for these shortcut methods is to perform comparison between powders. If a hopper is designed for a powder A and has a fairly satisfactory design, then checking Carr Index and angle of repose of powder B can give an idea if such a design could also fit for powder B. If the values of Carr Index and angle of Repose are very far, then it can be an indication that deeper work should be done to assess the characteristics of powder B and use rigorous methods for the design.

4. Electrostatics

One phenomena often overlooked in the analysis of powder flow is the influence of static electricity. This particularly true for very fine particles, for which the electrical forces become significant compared to other forces (gravity for example).

The parameters that will influence static electricity are the following :

- Moisture

- Intensity of friction

- Size and nature of particles

- Surface characteristics