Shear cells testing to measure flowability : Step by Step Guide

Measuring the flow properties of a powder with a shear cell. Calculations and interpretations.

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Jenike Method : Shear Cell Tester |

| 2. What can we get from a shear cells test ? |

| 3. Jenike Method : Step by step guide |

This page aims at explaining step by step how to determine the flow characteristics of a powder from a series of shear cells experiments.

What it is about

How to measure flowability of powders ?

There are different ways to characterize the flowability of powders. Many methods are quite empirical and give an "idea" rather than a quantification of the flowability of powders. The only powder flowability test recognized so far to generate flowability data that can be used to design an installation is to use a shear cell to test the powder and measure its flow characteristics. This method is sometimes called Jenike method from the name of Andrew Jenike who developed shear cells testing. It allows to calculate the following characteristics :

- Angle of internal friction

- Powder (Material) Flow Function (MFF)

- Angle of wall friction

Which can then be used to design hoppers ensuring mass flow (no flow blockage, no dead area in the hopper) with the method described in this page : link

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

The paragraphs below will describe the notion of powder flowability, which is actually covering different bulk solid properties :

- Cohesive strength

- Wall friction angle

It will also be explained how to practically determine those properties with a shear tester.

1. Jenike Method : Shear Cell Tester

Shear Cells

The Shear Tester or Shear Cell is a powder flowability tester that will allow to estimate very important powder rheology properties like the Cohesive strength and the wall friction which can in return be used to calculate hopper outlet diameters and angle of discharge

2 shear tests need to be done in order to determine the properties. 1 test is to measure the angle of internal friction ; for getting this property, the test cell will measure the strength necessary to make the powder slide on ITSELF. On the other hand, the wall friction angle will be determine thanks to a cell that is measuring the strength necessary to make a sample of powder slide on a MATERIAL plate, the material being commonly the metal in which the silo will be built.

|

|

Figure 1 : Jenike cells

The test is performed after a pre-shear step which will give a certain density of powder prior to applying the normal stress and the shear. This pre-shearing can be varied which will give different results. Those different results will be used to draw different yield locus and subsequently calculate different properties of the powder (see below).

Note that it is possible to make such a test on dedicated shear testers but that powder rheometers have also the possibility to run this kind of test by mounting a shear cell unit on their agitator.

2. What can we get from a shear cells test ?

The following powder properties can be determined from the

graph obtained (called "Yield Locus") :

Table 1 : Shear cells output

| Shear Tester | Direct determination | Calculated |

|---|---|---|

| Shear cell measuring material / powder interaction | Wall friction angle Φ' | - |

| Shear cell measuring powder / powder interaction | Effective Angle of internal friction δ Static Angle of Internal friction Φ Major principal consolidation (or compaction) stress σ1 Cohesive strength fc (also called Unconfined Yield Stress UYS) |

Powder (or Material) Flow Function (by drawing the couples UYS and σ1 obtained at different pre-shear) |

3. Jenike Method : Step by step guide

STEP 1 - Run the test

2 forces are a applied to a sample of powder. 1 normal, which is set, and that is being gradually increased. And the second to the side (shear force). This 2nd force is measured and corresponds to the force to slide the sample of material.

Each couple (Normal stress ; Shear Stress) is recorded and then plotted. From this curve, different powder rheology characteristics can be calculated. The graph obtained, called wall yield locus is shown below (example - not an actual powder)

STEP 2 - Draw Yield Locus

Powder - Powder interaction

For a given pre-constraint, draw the yield locus from the data obtained from the cell testing the interactions powder / powder. The angles of internal friction and the major consolidation strength can then be geometrically determined.

Figure 2 : data obtained from yield locus of powder - powder shear cell

Powder - Material interaction

Draw the yield locus from the data obtained from the cell testing the interactions powder / material. The Wall friction angle Φ' is then graphically determined.

Figure 3 : data obtained from yield locus of powder - material shear cell

STEP 3 - Calculate the flow function

The yield locus is performed according to an initial consolidation state. It is possible to vary the initial consolidation state. Drawing the different yield locus, at different initial consolidation, will give the basis to determine the flow function of the powder. An illustrative example, with 3 yield locus is given below.

Figure 4 : Graphical determination of powder flow function

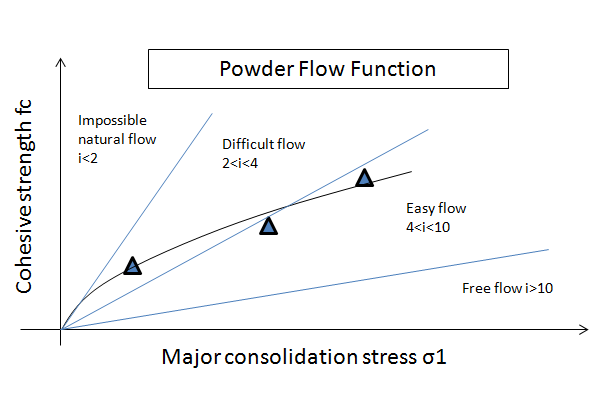

From the 3 different yield locus, 3 couples (Major consolidation stress sigma1 ; Cohesive strength fc) can be calculated. A graph showing fc=f(sigma1) can then be drawn. This is the material flow function of the powder being tested (not to be confused with the flow factor ff). The flow function brings key information on the behaviour of the powder, in a more reliable way than shortcut methods like the angle of repose or some indexes. In the example, only 3 couples are considered, but more will be used to draw the actual flow function. The graph can be divided in different areas by straight lines passing by the origin and with the slope i=(sigma1)/fc. The different values of i are giving information on the flowability, depending on the position of the flow function on the graph, its flowability can be determined.

Figure 5 : powder flow function and flowability of powder

Depending on the shape of the graph, we can determine if the powder is cohesive or not.

Figure 6 : Typical Material Flow Functions (MFF)

At the end of the testing with Jenike shear cells (or equivalent test equipment), the following powder rheology properties will have been determined :

- Angle of internal friction

- Powder (Material) Flow Function (MFF)

- Angle of wall friction

Note : it is then possible to determine how the powder will flow out of a given hopper (or design a hopper) by determining the flow function ff linked to a hopper design and plotting a line of slope 1/ff on the Material Flow Function MFF. Powder will flow if the line of slope 1/ff is above the MFF, if below, arches are expected to form and the flow to be difficult. More information can be found here on hopper design.

Figure 7 : Flow Function and Material Flow Functions to calculate Critical Applied Stress