Carr Index ⃒ Hausner Ratio

How is Carr Index calculated ? What is Carr's Index ? What is Carr's index formula ?

How is Hausner ratio calculated ? What is Hausner ratio ? What is Hausner ratio formula ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Powder

flowability characterization : Carr Index and Hausner

Ratio |

| 2. Calculation

formula of Carr Index |

| 3. Calculation

formula of the Hausner Ratio |

| 4. Interpretation and relation to flowability of Carr index and Hausner Ratio |

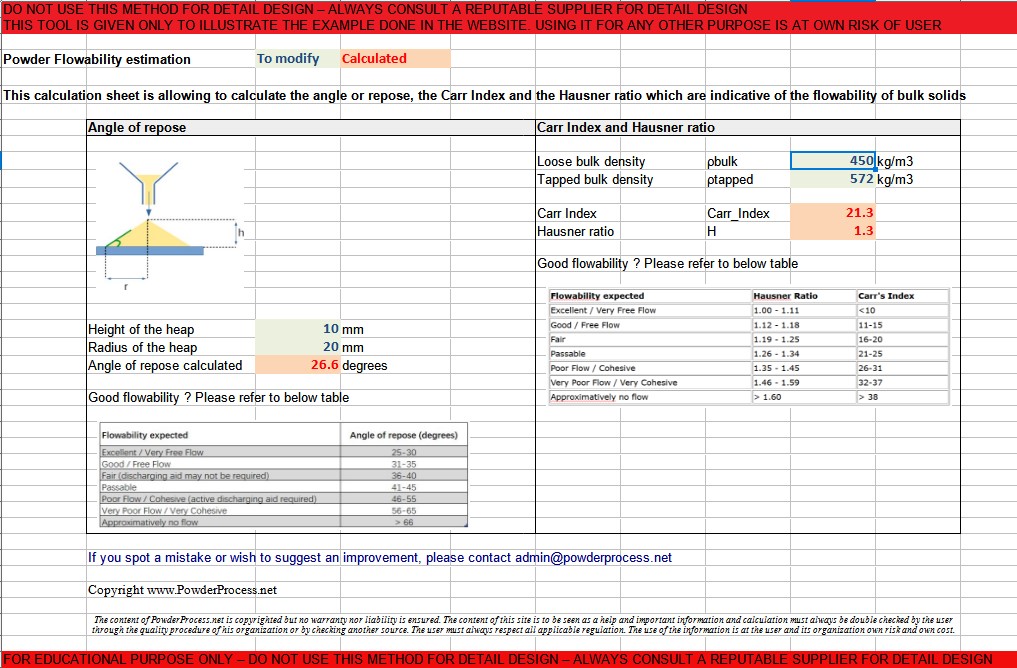

| 5. Carr Index and Hausner ratio Excel calculation tool |

1. Powder flowability characterization : Carr Index and

Hausner Ratio

The Carr Index and the Hausner Ratio are both meant as being indicators of the flowability of bulk solids. The flowability of solids is complex and linked to many parameters, it is thus not always obvious to characterize the solid flowability with the few set of data that Engineers usually have in hand during design or troubleshooting.

Both Carr and Hausner attempted just that : assuming that the compressibility of a solid is related to its flowability, they proposed to measure the bulk and tapped density of bulk materials and calculate a ratio in order to estimate how the material will flow.

The lower the Carr Index or Hausner Ratio, the more flowable is a material.

2. Calculation formula of Carr Index

How to calculate the Carr Index ? What is Carr's index formula ?

The Carr's Index of a material is calculated with the following formula :

Carr's Index Formula

Carr_Index = (ρtapped-ρbulk)/ρtapped*100

With

ρtapped : the tapped

bulk density of the material (kg/m3)

ρbulk : the loose bulk

density of the material (kg/m3)

It is possible to relate the Carr's Index and the Hausner ratio with the following formula :

H = 100/(100-Carr_Index)

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

3. Calculation formula of the Hausner Ratio

How to calculate the Hausner Ratio ? What is the Hausner Ratio formula ?

The Hausner Ratio of a material is calculated with the following formula :

Hausner ratio formula

H = ρtapped/ρbulk

With

H : Hausner Ratioρtapped : the tapped bulk density of the material (kg/m3)

ρbulk : the loose bulk density of the material (kg/m3)

There are other methods to define the flowability of powders or granules (click for more infos) :

4. Interpretation and relation to flowability of Carr index and Hausner Ratio

The flowability of a bulk solids is estimated by 1st calculating the ratio, then referring to the table below to determine in which class is the powder studied :

| Flowability expected | Hausner Ratio | Carr's Index |

| Excellent / Very Free Flow | 1.00 - 1.11 | <10 |

| Good / Free Flow | 1.12 - 1.18 | 11-15 |

| Fair | 1.19 - 1.25 | 16-20 |

| Passable | 1.26 - 1.34 | 21-25 |

| Poor Flow / Cohesive | 1.35 - 1.45 | 26-31 |

| Very Poor Flow / Very Cohesive | 1.46 - 1.59 | 32-37 |

| Approximatively no flow | > 1.60 | > 38 |

The table was determined by the authors of the method, by testing different material flowability, and calculating the compressibility ratio associated.

Note that Carr's Index and Hausner Ratio are approximate methods, the characterization of the flowability and the determination of physical parameters allowing the design of hoppers would require more measurement using powder rheometers or full shear cell testing.

Example of calculation of Carr Index

An Engineer wishes to have an idea of the probable flowability of a powder. He measures the bulk loose density as 600 kg/m3 and the tapped density as 660 kg/m3. He can then calculate the Carr Index :

Carr_Index = (ρtapped-ρbulk)/ρtapped*100 = (660-600)/660*100 = 9.1

Refering to the table above, the Engineer concludes the powder

is probably free flowing.

Example of calculation of Hausner Ratio

With the data above, the Engineer also wishes to define the Hausner ratio, he then makes the following calculation :

H = ρtapped/ρbulk = 660/600 = 1.1

The table above is also used, the powder is indeed probably free flowing.

5. Carr Index and Hausner ratio Excel calculation tool

Please access here the Free Excel calculator for Carr Index and Hausner ratio : calculator download (click here)