Angle of Repose : overview

What is the angle of repose of powders or granulates ?

Definition, measurement, calculation & interpretation

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Powder

flowability characterization : angle of repose |

| 2. Calculation

formula of the angle of repose |

| 3. Interpretation

and relation to flowability of angle of repose |

| 4. Angle of repose calculator Excel |

1. Powder flowability characterization : angle of repose

The angle of repose is used as an indicator of the flowability of bulk solids such as powders or granulates. It is a quick method that allows to get an idea of the flowability of granular materials. This page is proposing an overview of what is the angle of repose, why it is used and how it is calculated from experimental measurement.

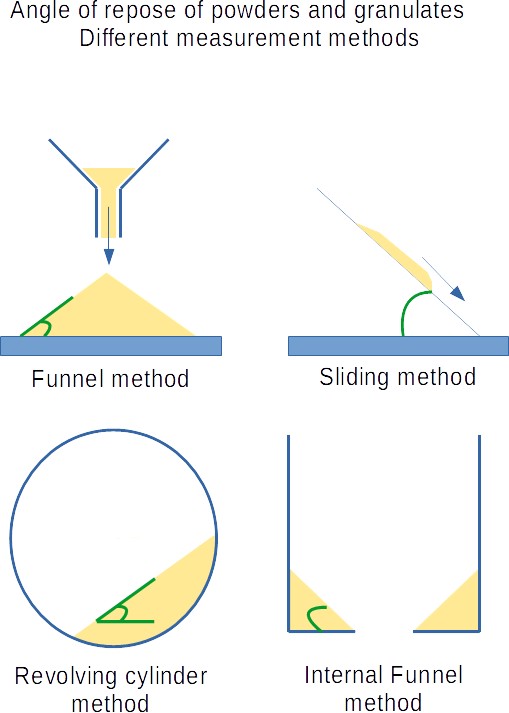

It's actually important to highlight that there are different angles of repose, depending on the methodology that has been used to measure it. The most common method is to have the material poured freely through a funnel, the material forming a heap. But it is also possible to measure an angle by sliding the material on a plate, using a revolving cylinder, or leaving the powder flow out of a smaller container through a hole.

Figure 1 : Different methods for measuring the angle of repose of powders and granulates

Those different methods are actually giving different values of the angle of repose. It is thus very important to know according to which protocol the angle of repose has been measured in order to be able to compare the flowability of materials. The funnel method (external funnel) is giving the lowest measure of the angle of repose :

| External funnel method angle | < Internal funnel method angle | < Sliding method angle |

The lower the angle of repose, the more flowable is a material.

The angle of repose is sometimes confused with the

angle of internal friction used in Jenike's theory to design

hoppers and silos, but the 2 values are not necessarily equal.

There are other methods to define the flowability of powders or granules (click for more infos) :

2. Calculation formula of the angle of repose

How to calculate the angle of repose ?

The determination of the angle of repose of a granular material can only be done through an actual experience. The methodology considered here is the most common, the external funnel method, done by pouring a certain quantity of solid from a funnel and measuring the angle of the heap of material formed.

To be noted that even for this funnel method, there are also some variations in methodology. For example, the funnel can be fixed or can be slowly moved up. A specified height of the heap can be the parameter to stop the experience, or it can be the diameter of the heap formed.

If the angle of repose method is used within a lab to characterize the flowability of different components, it is important to chose one protocol and keep it for all measurement.

Angle of repose formula

The formula to calculate the angle of repose is the following :

Angle_of_repose = arctan(h/r)

With

h : height of the heap (mm)

r : radius of the heap (mm)

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

3. Interpretation and relation to flowability of angle of

repose

The main application of the angle of repose is to assess the flowability of a granular material (powder, pellets...).

The flowability of a bulk solids is estimated by 1st measuring the angle of repose, then referring to the angle of repose table below to determine in which class is the powder studied :

| Flowability expected | Angle of repose |

| Excellent / Very Free Flow | 25-30 |

| Good / Free Flow | 31-35 |

| Fair (discharging aid may not be required) | 36-40 |

| Passable | 41-45 |

| Poor Flow / Cohesive (active discharging aid required) | 46-55 |

| Very Poor Flow / Very Cohesive | 56-65 |

| Approximatively no flow | > 66 |

Table 1 : angle of repose table

The angle of repose table was determined by the authors of the method, by testing different material flowability, and measuring the corresponding angle of repose.

Note that it is an approximate method giving trends, it can happen that a material behave differently once in the process. The characterization of the flowability and the determination of physical parameters allowing the design of hoppers would require a full shear cell testing.

Table 2 : angle of repose and expected flow properties

The angle of repose is also important to calculate the volume of material in hoppers or in stockpiles (for example in large open air or warehouse stock piles, or even in cargo ship transport).4. Angle of repose calculator Excel

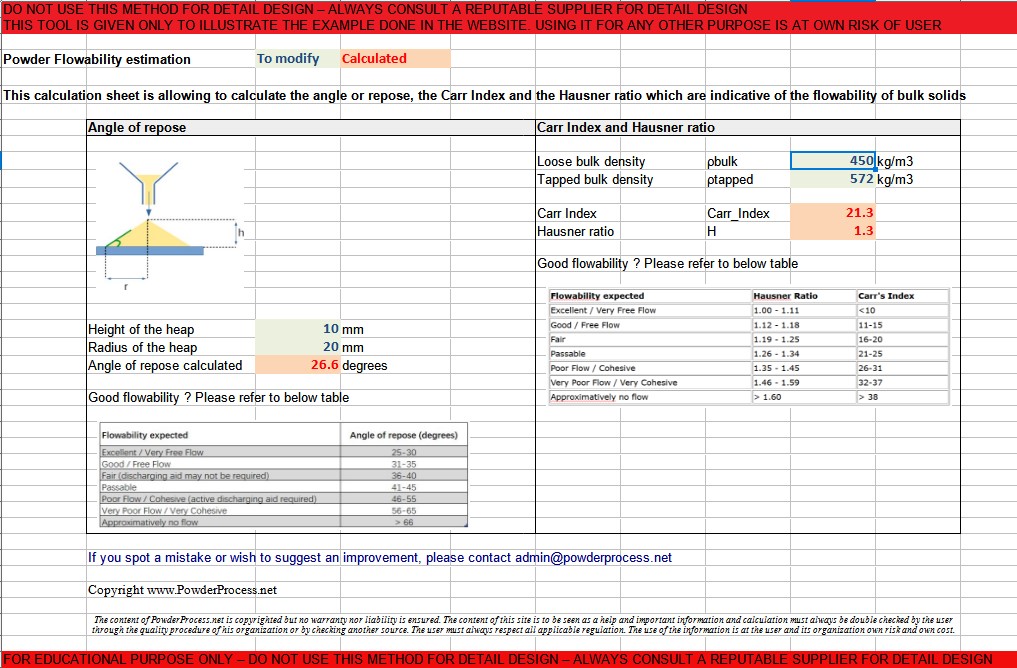

The following free Excel tool allows to calculate the angle of repose.

Angle

of repose calculator Excel download (click here)