Pneumatic Conveying Phase

What are the different pneumatic conveying phases ? How to determine in which phase a bulk solid / powder can be conveyed ?

Follow us on TwitterQuestion, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction |

| 2. Geldart Classification |

| 3. The different solids / air phases in a pneumatic transport line |

1. Introduction

There are different ways to transport pneumatically solids and one of the key difference in between each methodology is the phase in which bulk solids will be transferred in the pipe. By phase, we mean how dense the solid is when in movement. If very aerated, the phase will tend to be dilute, if less it will be dense phase. Typically, the amount of air used to transport the solids as well as the velocity are criteria used to determined in which phase is done the conveying. Not all solids can be conveyed in one phase or another, it all depends on the fluidization properties of the solids, on which the Geldart classification is useful.

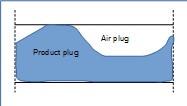

Figure 1 : examples of 2 transport phases, dilute on the left and dense on the right

2. Geldart Classification

How to know if powder can be conveyed in dilute phase or dense phase ?

Be careful, not all the solids can be transported with any technology. Actually, the adequacy of a particular technology will depend on the fluidization properties of the solid to be transported. Before designing a system, the class of the solid must be established. Such class is determined thanks to a classification proposed by Geldart in 1973.

It is a very shortcut method to classify powders according to their Geldart nature in order to determine if they can be transported dense phase. However, with this basic approach, the following can be considered.

Class A : powders adapted to dense phase conveying, they have a very high and lasting aeration. They can be transported at high concentration but do not form naturally some plugs, an active system is therefore required to create them.

Class B : sand-like powders, may be difficult to transfer in dense phase

Class C : these cohesive powders, may be difficult to transport in dense phase

Class D : these powders can be transported in dense phase at concentration in between class B and class A

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

Figure 2 : Geldart classification

Following Geldart classification is a 1st indication, with group B and C being the less suitable for dense phase conveying. However subsequent works have shown that among group B and C, some powders are able to transfer in dense phase, provided they have the right permeability and / or air retention. The air permeability allows indeed to fluidize the product and therefore change its rheology, while the air retention allows to keep the fluidized state a long time which can be interesting in a conveying pipe. As an indication, high permeability should allow to convey in plugs while a good air retention would allow a dune flow.

3. The different solids / air phases in a pneumatic transport line

What is dense phase conveying ? What is dilute phase conveying ?

It is important to understand how the concepts of lean phase and dense phase translate on the way the product is flowing in the pipe. Basically, depending on the velocity of the transporting gas, 5 flow regimes can be identified.

Table 1 : Conveying phases

| Gas speed | Flow regime | Conveying pipe Aspect | Comments |

|---|---|---|---|

| High speed (15-40 m/s) | Dilute Phase |  |

Basically, any solid can be transported in dilute phase,

however the constraints applied to the solid make it suitable

only for product which are not sensitive to breakage and which are not too

hard and abrasive for the piping. Particles are in suspension in the gas and are not depositing on the transport pipes. |

| Medium speed (8-15 m/s) | Dense phase (saltating flow) |  |

When the gas velocity decreases, the pressure drop decreases to a minimum and some particles form a continuous layer in horizontal pipe sections. Deposits are not permanent and conveying is actually happening. The concentration is not constant over a pipe section since more particles are at the bottom of the pipe. This type of conveying can be unstable and may lead to pipe blockages. |

| Low speed (3-8 m/s) | Dense phase discontinuous - Dune |  |

When decreasing further the gas velocity, the pressure drop increases again and a flow regimes where plugs are formed is appearing. The dune flow actually happens for fine products. The pressure drop will depend on the length of the plugs formed, thus the incentive to actively control them thanks to the process. One common method for this kind of flow regime is to install regular air injection in the pipe that will help to "cut" the plugs. |

| Low speed (3-8 m/s) | Dense phase discontinuous - Pulsating |  |

This flow regime is close to the dune flow presented above but is this time more happening with coarse materials. Observing the flow, it is clearly observed that it starts / stops, thus "pulsating". Plugs are created naturally thanks to the higher porosity of the solid compared to other more cohesive powders. |

| Very low speed (3-8 m/s) | Dense phase continuous |  |

Decreasing further the gas velocity, and for solids that are able to be conveyed under this regime, a continuous dense phase flow is established. Basically there is only one big plug. However, this creates very large pressure drops, which makes this regime limited to very short distances. |

It must be noted that the particles circulate at a lower speed

than the gas. Depending on the flow regime, the particle average speed can be 0.4 to 0.8

times the gas velocity.