Powder Rheometer testing : a guide to powder flowablity tests

Determining powder flowability with a powder rheometer

How works a powder rheometer ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Powder

rheometer : working principles |

| 2. Data from a

powder rheometer and interpretation to determine

flowability |

| 3. Data from a

powder rheometer and interpretation for dense phase

conveying |

Powder rheometers1 have increasingly been used over the last 10 years as a quick way to get flowability data on powders, the most common type of rheometer being the Freeman FT4. This page is explaining the working principle of a powder rheometer as well as how the flowability of a powder can be determined thanks to this kind of instrument.

1. Powder rheometer : working principles

Powder rheometers have been developped as an alternative, or a complement in certain cases, to shear cells testing which is the traditional method to test the flowability of powders and design hoppers and silos. The model of rheometer commonly found in industries is the Freeman FT4, the information given in this page being applicable for this equipment.

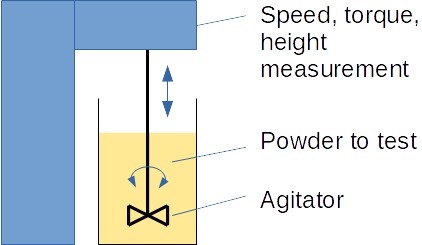

A powder rheometer is equipped with an agitator (an helix) which is plunged in a sample of the powder to test. The agitator is then rotated following different patterns and the speed, torque and height in the volume of powder are recorded. The data gathered can then be plotted and the flowability determined.

Figure 1 : Main components of a

powder rheometer

To be noted that the tests can be done with the powder in different aeration states. It is also possible, for some rheometer to fluidize the powder. These different states aim at simulating the actual conditions in the process. The higher the energy (torque) required to rotate the agitator, the more resistance to flow in confined powder flow processes and unit operations (-> less flowable in those conditions).

In certain cases, provided the correct/relevant accessories are

used, it is also possible perform a classic shear cell testing.

2. Data from a powder rheometer and interpretation to

determine flowability

How to measure flowability with a powder rheometer ?

The sample of powder is poured in the test beaker, and the agitator covered in the powder.

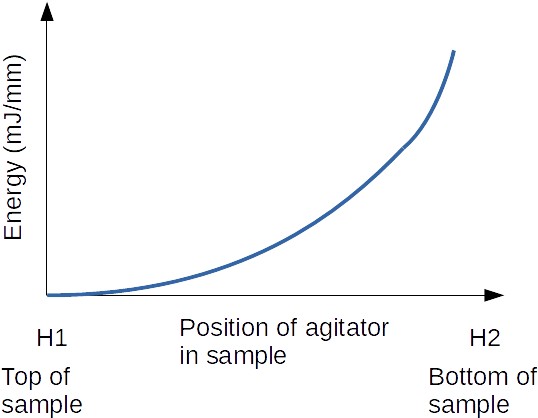

Different tests can then be peformed. The most common test is simply to measure the energy required when the rotating agitator is lowered down through the powder (Basic Flowability Energy BFE). The more energy is required, the more resistance to flow in confined processes and unit operations (->material less flowable in those conditions).

Graph 1 : Basic Flow Energy curve

obtained with a powder rheometer

It must be noted that it is difficult to interpret a single isolated result. The analysis becomes more relevant if a database is already available, with the energy curve, and that the actual flowability in the process of interest is known (the results of the powder rheometer allow indeed to define flowability in a specific process environment). Then it is possible with new substances to assess if the flowability is likely to be worse, equal or better than known compounds.

Other tests

A powder rheometer is measuring the flowability dynamically, which means that other tests can be performed, and the relevance of the tests must be defined according to the process in which is used the powder. The flowability energy, as shown above can be completed by the following measurement :

- Aeration

- Consolidation

- Flow rate

- Specific energy

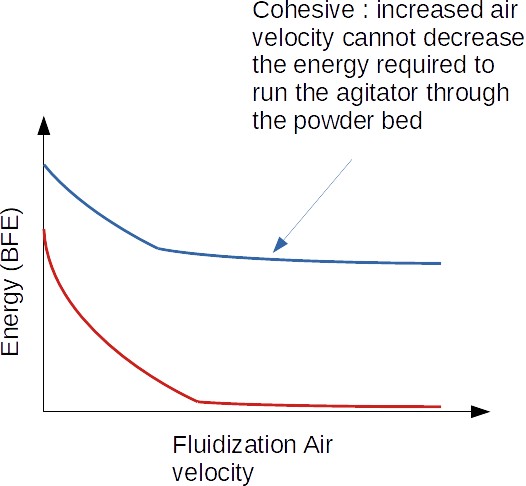

The aeration test is interesting to define how cohesive is a powder and how easily it will be fluidized. This bring information for hopper design (can we fluidize the powder to make it flow). The test is done in a similar way as for the flow energy, but the flow energy is this time measured at several air fluidization velocity by creating a fluidized bed. If the flow energy reaches a low plateau at high air velocity, it means it is not cohesive and will fluidize easily. On the contrary, if the plateau is reached at high energy, it means that the air is "channeling" through the powder and not really aerating it.

Graph 2 : Results of an aeration

test obtained with a powder rheometer

The consolidation test is measuring the flow energy, as a function of the number of taps used to increase the bulk density of a sample. The more the flow energy required increases with the consolidation of the sample, the more the product will be sensitive to long storage (in silos for example), or transport that will increase the bulk density.

The flow rate test allows to check if the powder flowability is changing with the flow rate at which it is made to flow. Cohesive powders will have different flow energy depending on the flow rate (simulated by a variation in speed of the agitator).

The specific energy test is interesting to measure if the particles have a tendency to "interlock" themselves (due to their shapes), which can help detecting a potential bad flowability, bad mixability (at least in some types of mixers) but in the contrary a capacity to reduce segregation once mixed properly.

3. Data from a powder rheometer and interpretation for dense phase conveying

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

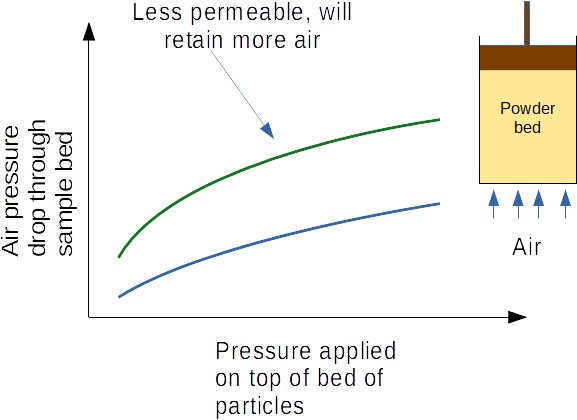

In dense phase conveying, it is important that the material be able to hold some air, keeps aerated, so that the material can create a pressure drop leading to the movement of the plug of materials. A test of permeability can be done, by applying a pressure to a bed of particules (to avoid expansion) and measuring the pressure drop of air through the bed of particules.

The higher the pressure drop, the lower is the permeability.

Graph 3 : Results and interpretation of a permeability test obtained with a powder rheometer

Note that there are other tests that can be done with a powder

rheometer, the tests above being the most common ones.