Solids Particle Velocity in pneumatic conveying (dilute phase)

Question or remark ? Please contact us at admin@powderprocess.net| Section summary |

|---|

| 1. Definition |

| 2. Calculation |

| 3. Usual values for dilute phase and lean phase pneumatic transport |

1. Definition

During the pneumatic transport of a powder in a pneumatic conveying line, the air is bringing the energy necessary to move the solids all along the pipe. Air velocity can be calculated easily thanks to the air flowrate and pipe diameter but it would be wrong to assume that the solid speed in the pipe is equal to the conveying air velocity, particularly in dilute phase. Indeed, the particles of solids won't be carried out all the way at the same velocity than the air as the particles will resist the air flow (drag), bounce on the pipe walls, settle... which will slow them down. As a consequence the particle conveying velocity will be less than the air conveying velocity. The factor in between the 2 velocities is called slip factor.

2. Calculation of solids particles velocity

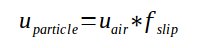

The particle conveying velocity is calculated from the air conveying velocity thanks to the slip factor :

Equation 1 : calculation of the particle conveying velocity

- up = solid particles conveying velocity (m/s)

- fslip = slip factor

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

----------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

3. Usual values of solids velocity for dilute phase conveying

Straight pipes

Typical values of slip factors and thus of solid particles conveying velocity can be found in litterature [1].

Table 1 : Usual values of slip

factors

| Particle | Slip factor |

|---|---|

| Usual range all

kinds of particles |

0.7-0.95 |

| Coarse particle |

0.8 |

| Fine powder |

0.9 |

Bends

In 90 degrees bends, the solids slow down further and the exit velocity is equal to around (0.8*entry velocity). It takes around 20 pipe diameters to reaccelerate the solids after the bend.

This last relationship explains also why it is important not to have consecutive bends in a pipe layout : the solids will slow down and finally deposit, which may choke the line.

Source : [1] Theory and Design of pneumatic conveying Systems, Agarwal, Powder Handling and Processing, 2005.