Plastic pellets conveying : avoiding angel hairs, streamers and

fines

Do you have a question, a remark ? Please contact the author at admin@powderprocess.net

| Section summary |

|---|

| 1. Fines and streamers : where is it coming from ? |

| 2. How to avoid streamers when conveying plastic pellets ? |

| 3. How to avoid fines when conveying plastic pellets |

| 4. How to remove fines ? |

When conveying pneumatically plastic pellets, factories usually face 2 types of problems : the creation of streamers and of fines. Those materials are perceived as defect by customers and can also create issues in the conveying line. This page is explaining how fines and streamers are formed, and how to avoid, or at least, reduce them.

1. Fines and streamers : where is it coming from ?

When conveyed pneumatically, plastic pellets are hitting the conveying pipe and rubbing against it. This can translate in the creation of streamers and fined which are a concerns for large polyolefins manufacturers (PE, PP...) and their customers.

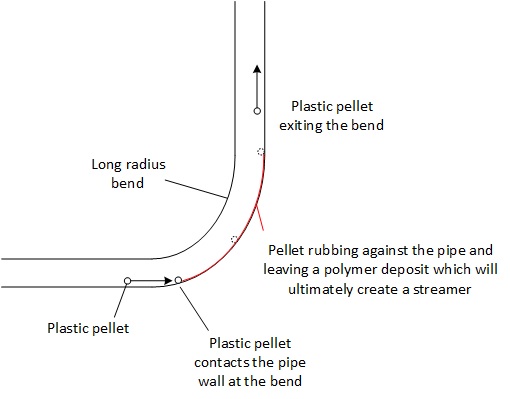

Streamers are formed when plastic pellets are conveyed at high velocity in a smooth pipe. The pellets then very often hit the pipe wall and slide against it. During sliding, a bit of material melts and sticks against the pipe. The repetition of the phenomena is making the deposit of material grow until it peels off from the surface of the pipe. If the peeling happens early, there will be only a thin wire of plastic, often called angel hair, if it happens later, the band of plastic will have grown several cm long and wide and will create a streamer. Those polymer ribbons can actually group together at the end of a conveying line and create plugs in hoppers or valves. If they are bagged with the good pellets, they will constitute quality defects once at the customer factory.

Fines are more the results of pellets hitting the pipe at high velocity, rebounding and having a little part of the pellet breaking on the impact. The small part is then carried pneumatically and constitute a fine.

2. How to avoid streamers when conveying plastic pellets ?

Streamers are created when plastic pellets can slide for long distance on the pipe wall. This phenomena is promoted when pipes have a smooth surface, and when there are long radius bends which keep the pellets on the outside curvature of the bend for a long time.

Figure 1 : mechanism of creation of

a streamer in a pneumatic conveying pipe

Dilute phase conveying system : when conveying pellets in dilute phase, the following changes can then be applied :

- Install pipes which have a rough surface via sandblasting or directional shot peening

- Reduce the bend radius

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

Those recommendations may actually increase the pressure drop, thus the system must be designed specifically for this or the line design should be checked before any modification.

Having a rough pipe and short radius bends is actually contrary to most of the design options that are usually taken for pneumatic conveying and are quite specific to plastic pellets handling. Pneumatic conveying in food will for example focus on the contrary in having very smooth pipes to reduce possible product retention and having long radius bends to avoid particle breakage.

Dense phase conveying systems : another option, which is actually the most efficient, is to reduce the velocity of the conveying. It can be done within certain limits for an existing system, but for a new system dense phase conveying may be considered.

3. How to avoid fines when conveying plastic pellets

Fines are created when the pellets are hitting each other, or the pipe wall, at high velocity.

Dilute phase conveying system : if you have a dilute phase system, they can be limited by reducing the conveying velocity (trials required to optimize the velocity while avoiding pipe plugging), making sure all pipe coupling are well aligned, using a smooth pipe long radius bends or special bends. Note that these latest recommendations are actually contrary to what will reduce the streamer formation, there is thus a trade off to find, although using special pipe treatments like sandblasting and directional shot peening can reduce fines creation. If possible to replace the piping, review the pipe layout to see if there is a way to have less bends, and consider stepping the pipe diameter to reduce the end of line velocity.

Dense phase conveying system : conveying at low velocity

will very much reduce the generation of fines, although there will

still be some that will be created.

4. How to remove fines ?

In case fines are still present despite implementing the advice above, it is possible to install an elutriator at the end of the pneumatic conveying line which will allow to separate the fines, and send them to a filtration system, from the pellets.

For streamers and angel hair, a sieving system (vibrating

sieve) could be installed.