Stepped pipe

Use of stepped pipeline in pneumatic conveying

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. What is a

stepped pipe ? |

| 2. Precautions

when using a stepped pipe |

1. What is a stepped pipe ?

The driving force of any pneumatic conveying system is a pressure gradient in between the beginning of the pipe and the end of the pipe. The pressure is always higher at the beginning of the pipe compared to the end of the pipe so that a draft of air, transporting the solids materials, can establish. This is true in both pressure and vacuum conveying.

As a consequence, when the air travels down the pipe, the pressure decreases. This in turn is causing the expansion of the air. As the air expands, the velocity of the air must increase as the mass flow remains constant. This means that the velocity towards the end of the pipe is higher than at the beginning of the pipe.

If the velocity gets too high, this can be detrimental for the pneumatic conveying system. Among the possible consequences of a too high velocity are :

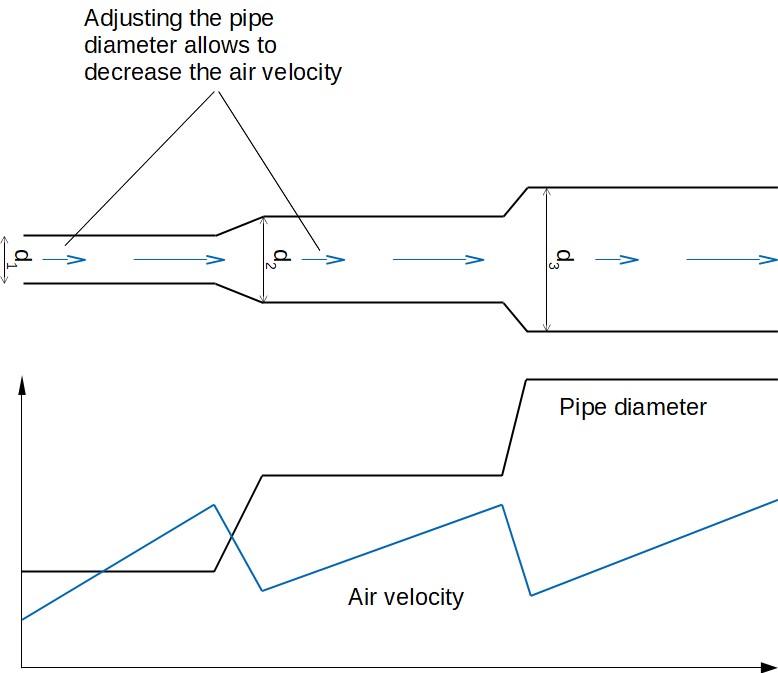

It may then be necessary to adjust the air speed in order to stay in acceptable conditions. One way to do so is to step the pipeline, which means increasing the diameter of the pipe to account for the expansion of air and keep the air velocity as constant as possible all along the pipe length. Stepped pipe is thus a pipe made of several sections of growing diameter.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

---------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

Figure 1 : Stepped pipe and air velocity profile

2. Precautions when using a stepped pipe

In principle, a stepped pipe look to have many advantages. The Engineer designing a conveying line should however be wary of some potential issues with this strategy.

The 1st one is the cost, stepping the pipe will add in complexity and costs. An economic study should be done to verify that an acceptable result cannot be achieved by reviewing the whole pipe diameter, blower, solids load ratio... to adjust the pressure drop in the pipe and the expansion and speed expected at the end of the line.

The 2nd one is the actual velocity in the stepped pipe sections. Indeed, one must verify that the air velocity will in any case stay above the saltation and choke velocity of the particular product conveyed, otherwise the material may slow down too much and finally block the pipe.This has also to be considered if a pipe flushing step needs to be done (cleaning the pipe by reaching higher velocity to remove material that may still be in the pipe, settled).