Powder Build-up in conveying pipes

What are the root causes of build-up of materials in pneumatic conveying line ?

How to solve the buildup of powder in conveying pipes ?

Question or remark ? Please contact us at admin@powderprocess.net| Section summary |

|---|

| 1. Definition of

powder build-up |

| 2. Explanation - root causes of powder

build-up |

| 3. How to reduce product build-up in pneumatic conveying |

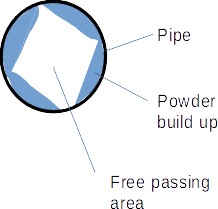

1. Definition of powder build-up

It happens that factory operators sometimes notice that the pressure drop in the conveying pipe is steadily increasing over time leading to a stoppage of the conveying line. When the pipe is opened, an accumulation of material is often found, which it is necessary to remove. This kind of pipe blockage is very different than a sudden stoppage of the line, often due to a surge in the quantity of product in the pipe, since it happens progressively. This product accumulation is said to be a build-up.

2. Explanation - root causes of powder build-up

Why are powder buildup happening in pipes ?

Actually, there can be many different root causes leading to a build-up of product in the pipe. Typical causes are issues with the conveying air quality, having a very fine material to convey or having a cohesive / sticky material to transport.

2.1 Conveying air conditions

If the air transporting the material is too humid at the transport conditions, then the material can pick-up some humidity and have a tendency to cake. This, in return, makes it easy for the material to adhere to the conveying pipe, creating layers of materials that will ultimately block the pipe.

It is thus very important to control the relative humidity of the transport air and make sure it is low enough to avoid transferring water to the conveyed material. The relative humidity must be calculated in the pipe (in and out conditions) as the pressure increase at the beginning of the line in the case of pneumatic conveying will change a lot the relative humidity of the air.

Some authors also reported seasonal problems where the conveyed material is cold and below the dew point temperature of the air, triggering a condensation of the water contained in the transport air.

2.2 Fine material

Some sources as well report issues created by very fine particles < 10 microns. These particles are indeed so fine that they can settle close to the pipe where there is a very fine layout of laminar fluid flow. Once they enter this area, they adhere to the pipe wall and initiate the build-up. [1]

2.3 Cohesive / sticky material

The most common causes are to have a very cohesive material or a sticky material. Under the impact on the pipe, especially at bends, the powder is getting compacted - in the case of a cohesive material - or adhere - for a sticky one. Stickiness is often related to the nature of the material for example if there are large amounts of fats. Some materials may also change properties just at the impact, due to the energy involved.

Note that the conditions of temperature and humidity in the pipe may make sticky a material that is not causing problem in ambient conditions. It is especially the case for materials having a glass transition temperature.

Build-up will most probably happen at bends, as particles will all impact in a reduced area, although some powders can also cause issues in straight pipe sections.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

-------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

3. How to reduce build-up in pneumatic conveying lines

As seen, some materials are by their properties causing build-up, thus build-up may not be totally avoided but controlled through different measures :

- Convey at the minimum possible speed : as build-up happen at bends and is often related to the strength of the impact, reducing the conveying air velocity should have an impact

- Change the pipe bends radius : too sharp bend radius may be change for long radius pipe, it should however be noted that long pipe radius may be detrimental in other way for some materials (angel hairs for polymers pellets for example)

- Use flexible pipes : having flexible pipes allow to break the build-up and avoids that the accumulation grow to the point of blocking the pipe [2]. It is not always possible to use this method in some industries.

- Review the conveying conditions : adapting air temperature and humidity may be a solution for some materials

- Convey dense phase : conveying dense allows to reach very slow air conveying velocity, thus avoiding impact and build-up.

As mentionned above, some other phenomena may be involved in the build-up, one could be static electricity which accumulates fines.

Sources

[1] Powder Bulk Engineering, Ask the Expert, Managing fine material build-up in conveying line, 2017

[2] Powder Bulk Engineering, Pneumatic Points to ponder, Diagnosing

and fixing material

buildup problems in conveying lines, 2008