Big Bag Handling safety

Good practices to ensure a safe handling of Super Sacks

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction |

| 2. Load |

| 3. Safety cage |

| 4. Access to downstream equipment |

| 5. Have a safe access to the working platform |

1. Introduction

Big Bags (also called super sacks in US) are getting more and more common as factory owners try to get efficiency in their process. Such large packaging however present some specific safety risks that it is necessary to manage. Bags can indeed weight 500-1000 kg and sometimes more. If a Big Bag that was lifted is falling down on the operator, it can lead to a fatality.

This page is summarizing the precautions to be taken during design and operation to have a safe handling of Big Bags.

2. Designing for the right load

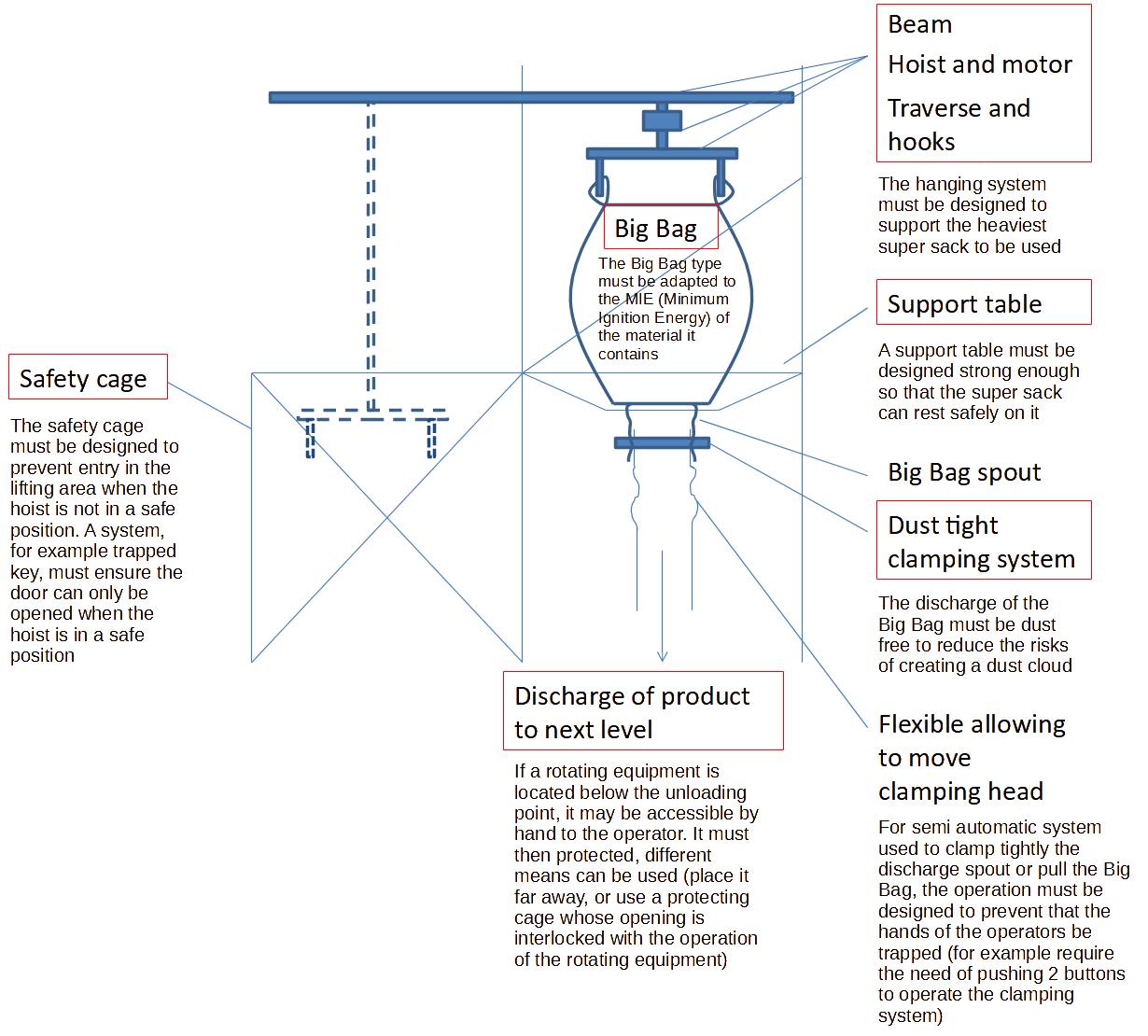

The whole station must be designed to handle the load of the heavier Big Bag that will be tipped. The factory operator must chose a Big Bag fabric that has a Safe Working Load (SWL) higher than the maximum weight of material that is filled in the Big Bag. The beam / hoist used to lift the super sacks must also have a SWL correctly sized.

It is important to re-validate this load during trials or change of suppliers as different Big Bags weight may be used.

Another consideration is that super sacks cannot be re-used

multiple times if they are not designed for this. There are indeed 2

types of Big Bags : single trip, which must be discarded after a

single use, or multiple trips that can be reused a defined number of

times (it is very important to track how many time each Big Bag is

used). Single trip super sacks have a lower safety factor SF

(5:1) compared to multiple trips Big Bags (6:1).

3. Have the right safety cages

The area below the lifted Big Bag must be protected to make sure that nobody is standing below the load when lifted. It is important to have in mind that accidents where the Big Bag falls do exist : it can be caused by a defect in the hoist, a defect in the traverse, Big Bag hanging loops not properly attached or a re-used Big Bag that finally breaks.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

----------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

For permanent stations, a cage should be installed with proper dimensions to make sure that nobody can get in when the Big Bag is lifted. It is also recommended to interlock the door of the cage to the position of the hoist : it should not be possible to open the door if the hoist is not in safe position, and it should not be possible to move the hoist if the cage is opened.

For temporary lifting, some barriers should be installed and a

safety officer should overview the lifting to make sure nobody

enters the hazardous area.

4. Protect the access to equipment downstream

Another aspect to take into consideration for the overall safety of the dumping station is to make sure there is no access to rotating equipment below the tipping point. A typical safety risk is happening if the powder is not flowing well in the downpipe of the station : the operator reaches inside to unblock the powder and can get into contact with a rotating equipment that may be positionned below, like a screw conveyor or lump breaker.

This risk should be taken into consideration by the factory with possible measures including : positioning the rotating equipment downpipe out of reach, welding a grid in the downpipe (efficient, but may create flow issues), or having a cage with a proximity switch cutting off the power on the rotating equipment if opened.

Additonally, Big Bag dumping stations are often equipped with a mechanism to clamp the spout of the Big Bag during discharge. This mechanism should be designed to avoid that the operator gets fingers squeezed by the clamping mechanism. Having a manual lock can be sufficient, while an automatic system will need that the command buttons be activated by the 2 hands of the operator.

5. Have a safe access to the working platform

Very often the Super Sacks unloading stations are elevated in order to have sufficient height to place the necessary equipment just below the bag spout clamping system and discharging tube. As a consequence, a platform must be installed for the operator to reach the area where he needs to pull the Big Bag spout, clamp it to the discharging head and open it. As the operator is likely to go up and down the platform very often it is important to respect some design rules to minimize the risks of accident while the operator is working :

- Respect the stairs good design rules : they should not be too steep

- Have handrails positioned continuously on the platform and along the stairs

- Make sure that the stairs landing is offset compared to the working position on the operator on the platform (avoid that the operator steps backwards in the stairs while working on the platform).