Lump Breakers : an overview

What is a lump breaker ?

How is designed and operates a lump breaker ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. What is a lump

breaker ? |

| 2. Lump breaker

working principle |

| 3. Lump breakers

design |

| 4. Industrial lump breakers |

| 5. Applications |

Lump breakers are used in bulk solids handling to reduce the size of undesirable agglomerate that may form typically when storing powders. This page is focusing on the best design of lump breakers found in the industry.

1. What is a lump breaker ?

Bulk solids are sometimes subject to lumping, caking, leading to the agglomeration of the individual solids particles into a bigger chunk that can reach several cm or dozens of cm in some cases. When this happens, lumps are causing important operational problems as they can block pipe, equipment, and reduce the capacity and or / quality of a production process.

A typical example is sugar, if sugar is submitted to variation of humidity, water may condensate, then evaporate, creating solid links in between sugar granule, thus creating a lump.

Lump breaker aim at crushing the agglomerate so that the individual particles are recovered, as well as the properties of the bulk solids, especially its flowability.

It is important to understand that lump breakers (usually) are not aiming at getting a finer material than the solids caked, but just separate the individual particles and recover the original particle size distribution (PSD) observed in the material before caking.

2. Lump breaker working principle

How does a lump breaker work ?

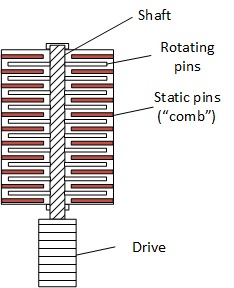

Lump breakers are made of a rotor and a stator. The rotating part is typically designed with one shaft on which are welded pins. The stator part is also made of pins, sometimes called "comb", the rotating pins are passing in between 2 static ones.

The fine powder is flowing easily through the machine, in between the pins, and with the rotation of the pins. However lumps are stuck in between pins and crushed. The fineness of the product obtained is then a function of the gap in between the pins.

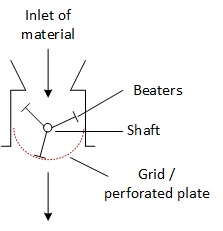

Some more specific designs are using 2 rotating shafts, counter rotating, with the "combs" on the side of the lump breaker. Some other designs are using principles closer to hammer mills with some kind of beaters and a perforated plate allowing to size the material leaving the breaker.

3. Lump breakers design

3.1 "Comb" design

The simpler lump breakers are using a system of static pins that are intermeshing with the teeth or blades of the agitator in order to break the lumps. The gap in between the "comb" of static pins (also called a breaker grid or breaker bars) and those of the agitator is determining up to which size the lumps will be crushed.

Figure 1 : Lump breaker top view diagram

3.2 Lump breaker with sizing grids

Other designs of lump breakers, allowing to reach a more define and often finer particle size distribution are equipped with a mesh or perforated plate at the outlet of the crusher, and have also agitators that are more looking like beaters found on other kind of grinders.

Figure 2 : Lump breaker with sizing grid at outlet

3.3 Shafts

It is possible to have 2 shafts, instead of one, especially for the crushers without sizing grids but a comb. The shafts are indeed counter-rotating and thus each shaft can contribute to the grinding in crushing material on the combs installed on each sides of the crusher.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

3.4 Shaft speed

Lump breakers are usually operating a low speed (75 rpm), the breakage being more a question of torque than speed. Some lump breakers, which are then operated closer to mills, are using higher speed (>1000 rpm [Stolhanske]). The speed required will also be a function of the application depending on how hard are the lumps, and how fine they must be grounded.

3.4 Drive

Due to the nature of the unit operation they perform, lump breakers can be subject to overload in case, for example, too hard lumps are processed, or sticky material accumulates and blocks the crusher. As a consequence, it is important to consider a current overload protection. For big lump breaker, mechanical protection may be required, such as an air clutch.

3.5 Product feed

It is preferable to control the feed to the lump breaker (at least roughly) by a dosing equipment such as a vibrating tube, a screw conveyor, or an airlock rotary valve. In some cases, the breaker may be operated in load, below a hopper, but in any case the outlet must be free of product otherwise the rotation of the shaft is not possible.

3.6 Product discharge

The discharge of the mill must in general be free, which means that product should not accumulate below the agitators. If the lump breaker is discharging to a hopper, level sensors must be positioned in the hopper to prevent product reaching the outlet of the crusher. if discharging to a any kind of conveyor, the conveyor capacity must be higher than the product inlet flow to the crusher.3.7 Stand alone lump breakers

Small lump breakers can be mounted on chassis. It is then possible, for small capacity applications, to 1st pass the material through the lump breaker and collect it in bags before tipping it to the main process.

3.7 Safety

There are typically 2 main risks linked to lump breakers :

- Occupational safety : the access to the rotating part of the breaker must be prevented. This can be done through guarding or interlocking, but the "0 access" principle must be respected. This should encompass the protection of the access from the inlet, but also from the outlet or through inspection hatches the crusher may have.

- Dust explosion : lump breakers must be the object of particular attention when carrying out DHA (Dust Hazard Analysis) or ATEX risk assessment. Indeed, the shaft rotating speed must be limited to avoid mechanical sparks, but also risks or product accumulation that may lead to overheating must be considered.

Operating a lump breaker must therefore be done ONLY when occupational and dust explosion risk analysis have been performed and the conclusions implemented.

4. Industrial lump breakers

Industrial

lump breakers exist in different sizes. The inlet is usually

rectangular or squarish, ranging from 8 in, 12 in, 18 in, 24

in... for the most common models, up to 36 in * 80 in for twin

shaft lump breakers used in mineral industries. The drive

power being in the range 2-20 HP for regular breaker up to 60

HP for the bigger models.

The capacity depends on the design, and especially the sizing screen if the lump breaker is equipped with one. The range found on supplier's brochure is from 1.5 m3/h up to 125 m3/h for larger machines. For machines equipped with a sizing grid, particles of several cm can be broken down to particles of several mm. For machines using a comb for the size reduction, the particle size expected will be somewhat coarser but it all depends on the application.

In

order to be resistant to wear, the lump breakers, usually made

of mild steel or stainless steel, can be made of special

alloys or with special anti-wear coatings.

The following company are manufacturing lump breakers :

Mecaroanne : https://www.mecaroanne.com/en/grinding-breaking-crushing/know-how

Palamatic

process :

https://www.palamaticprocess.fr/machines-industrielles/emotteur

5. Applications

Lump breakers can be used in many bulk solids industries whenever there is a risk to have an unwanted agglomeration of the processed material. The following examples give an idea of the variety of application in which are used those crushers :

- Coal

- Charcoal

- Alu-Magnesium

- Cocoa

- Sugar

- Chocolate powder

- Salts

- Bentonite

- Coconut

- Fertilizers

In general dry and friable products are the ones that perform best in lump breakers. It is however possible to proceed more humid, sticky materials, but in this case, a transparent exchange with the supplier is required as the design may have to be adapted (for instance sticky materials may block a sizing screen).

Source