Roller compactors : basic principles and technology overview

Dry granulation by roller compaction

How does a roller press work ?

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. What is a

compaction roller press |

| 2. How does the

powder stick together when going through a press ? |

| 3. Compaction

Roller presses working principle ? |

| 4. Compaction Roller presses applications |

| 5. Compaction Roller presses manufacturers |

Roller presses are used to process bulk solids (powder, granules) in order to perform a dry granulation by compaction. They can typically produce a compacted sheet of material that is later milled, even if some models have specific rollers whose shape allows to produce some briquettes. This page is focusing on the design of roller presses, the mechanisms behind the agglomeration of the material which goes through a roller compactor, and the different applications of this technology.

1. What is a compaction roller press ?

Roller compactors used for compaction of powders are all using counter-rotating rolls maintained in position by a mechanical or hydraulic system that is typically applying a force to one of the cylinders, called the floating roll.

The material is introduced in between the 2 rollers to be compacted. The compaction can be done in between 2 smooth rollers in which case a film or band / sheet of compacted material is produced, however the rollers can also be made of a specific shape that allows to produce pieces of compacted powder.

Figure 1 : Roller press working principle

If a band of compressed material is produced, it is often milled afterwards in order to recover a granulated product that can be sold or processed further (for example to produce tablets in a tablet press), thus the machine is often called roller press granulator.

2. How does the powder stick together when going through a press ?

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

When the powder is going in between the 2 rollers, it is submitted to the pressure of the rolls which leads to a dry agglomeration of the material. This dry granulation is allowed thanks to different mechanisms that, at the particle level, allow to keep the material together :

- Creation of solid bridges in between particles by

- Chemical reaction

- Melting or sintering

- Adsorption layers

- Non valence associations

- Molecular, electrical, magnetic forces in between particles (for example Van Der Waals forces)

- Interlocking

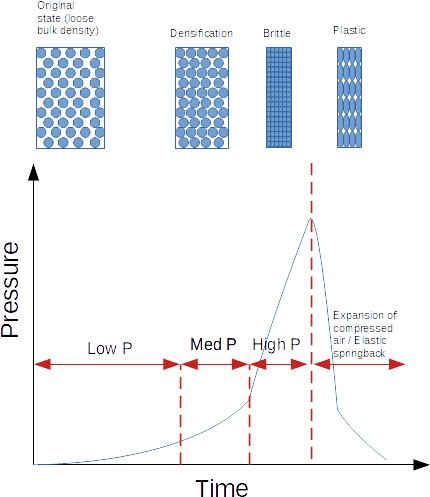

As for similar compaction processes (like tablet presses), the powder is 1st rearranged, densified, then is broken down and deformed by the pressure. The intimate contact resulting from this compression allows bonding in between particles to be created. After compression, the material usually re-expand a little bit. The graph below is illustrating those differences changes in the powder structure according to the pressure it is exposed during the compression process.

Graph 1 : the mechanisms of

pressure agglomeration with the different stages reached and

impact on the material [Pietsch]

3. Compaction Roller presses working principle ?

The compression of powder is performed according to the following steps [Pietsch] :

- Powder supply, densification and force feeding to rollers : the bulk material to be compacted is brought to the press thanks to a powder handling system (for example using pneumatic conveying, or simple gravity feed) then is introduced in a hopper directly connected above the rollers. This hopper is often equipped with one or several screw feeders that allows to force the feeding of the materials to the gap in between the rollers. The screws allow to build up pressure, densify the materials and improve the feed to the rollers.

Figure 2 : Force feeding of powder to nip area with a screw feeder

- Powder deareation : while the powder is densified, the porosity decreases which means there is less space for air. Air must therefore escape the powder all along the 1st densification steps right above the 2 rollers. If deaeration is not completed properly this can lead to severe quality defects after compression, as, after going through the gap in between the 2 cylinders, air can suddenly expand and break the agglomerate.

- Compression : the counter rotation of the rolls allows to drag the material in the center area in between the 2 rolls, densify it and finally bring it to the nip area where the actual compression work starts. A nip angle is helping to define this area. Going through the nip area, the material finally passes through the area in between the 2 cylinders where it is submitted to a very high pressure. It is this very high pressure that allows to compact the powder sufficiently to agglomerate it.

- Discharge : the high pressure area in between the 2 cylinders is actually quite small, immediately after compaction the material is thus pushed away by the counter rotating rolls. Right after discharge an enlargement of the compacted material sheet is observed.

4. Compaction Roller presses applications

- Pharmaceuticals (generally special hygienic designs)

- Chemicals / Fertilizers / Detergents

- Sodium carbonate, sodium chloride, sodium sulphate, sodium nitrate, ammonium chloride, iron sulphate, calcium chloride, foundry additives

- sodium sulphate, sodium chloride, carbonates, sodium cyanide, potassium cyanide, iron sulphate, potassium bromide, boric acid, urea (for briquetting)

- PK, NPK, potassium chloride, potassium sulphate, ammonium sulphate, potassium nitrate, phosphate, potash slag

- Steel

- Turnings

- Waste materials or by-products

- Mining, ore and minerals industries

- uranium oxide, chromium oxide, iron oxide, zinc oxide

- lime, dolomite, magnesia

- Nickel ore dust

- alumina, bauxite, lime, dolomite, gypsum, china clay, magnesia, fluorspar, paint pigments, Sulphur (for briquetting)

- Metallic oxides (Waelz oxides), rare earth oxides, zirconium hydroxide, ferro-alloys, molybdenum trioxide, zircon sand (for briquetting)

- Coal

- Catalysts

- Polymers

- Dried sewage sludge

5. Compaction Roller presses manufacturers

Roller presses range from small machinery for pharmaceuticals to

very heavy systems for chemicals, fertilizers and mining

industries. It is thus important to select the products of a

company having a strong and proven experience that will allow to

deliver reliable, performant and easy to maintain machines. Among

those companies, the company Sahut-Conreur (sahutconreur.com) can

be mentionned.