Tablet presses : an overview

Single punch and die reciprocating presses

Rotary punch and die presses

What is the working principle of a tablet press ?

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. What is a

tablet press ? |

| 2. How does the

powder stick together due to compaction ? |

| 3. Tablet press

working principle |

| 4. Factors influencing the choice and design of a tablet press |

| 5. Tablet press manufacturers |

Tablet presses, and more generally rotary punch and die presses, are used in various industries to compact powder and granulates and then produce a tablet that can be easily handle, sold, and absorbed by the customer. Those machines are of course widespread in pharma industry and also now in the growing food supplement industries. The same compaction principle is however found in heavier industries for example producing refractory bricks although the machine size is different and is rather not of the rotary type but more a single stroke machine.

1. What is a tablet press ?

What is tablet punching ?

A tablet press machine is an equipment which allows to agglomerate powder or granules thanks to compaction. The process, dry, consists in having a blend of powder or granules (powder which have been submitted to a prior step of granulation such as wet agglomeration), introduce the powder in a die, and apply a high pressure with a couple of punches. The pressure is compacting the powder, deforms it, and makes it adhere together.

- Reciprocating punch and die presses : the simplest machine have a single die and operate according to a reciprocating movement with upper and lower punches alternatively closing and opening to compact and then eject the compacted powder under the form of a tablet or a briquette. These machines have a low throughput but are commonly used to manufacture metal pieces for example, or refractory bricks.

- Rotary punch and die presses : the principle remains the same, punches are closed on product contained in a die to compact it, but many punches and dies are mounted on a rotating ring which allows to tremendously increase the punching frequency. These machines are however used mainly in pharma and produce very small compact of powders of few grams. The number of tablets produced is therefore high, but the mass throughput of the machine remains a few dozens or hundreds kg per hour.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

2. How does the powder stick together due to compaction ?

How do you make tablet powder ?

Compaction is basically a dry process during which solids particles are made to stick together and keep a certain shape thanks to the action of a high pressure. When compacting the powder, different phenomena take place that allows to get a tablet or a briquette (for bigger machines), those phenomena are listed below, although only some of them may be at play for a given application [Pietsch] :

- Creation of solid bridges in between particles by

- Chemical reaction

- Melting or sintering

- Adsorption layers

- Non valence associations

- Molecular, electrical, magnetic forces in between particles (for example Van Der Waals forces)

- Interlocking

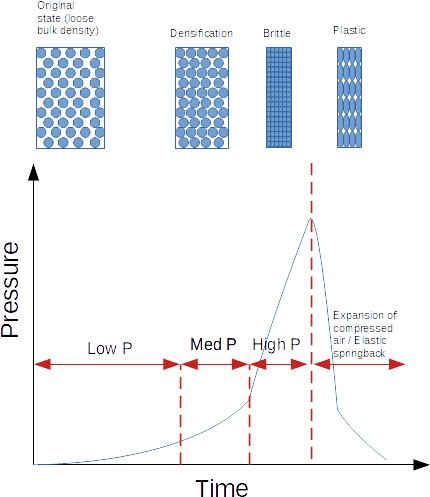

In any case, the compression forces must be such that the solids particles are withstanding a plastic deformation [Perry] which is leading to a very intimate contact in between particles leading to some of the bonding phenomena mentioned previously. A typical compression cycle and its effect on the solids particles is represented in graph 1. It should be noted that the materials, after compaction, and once the pressure is released are usually slightly expanding due to the release of compressed air and / or a form of elastic recovery of the material [Pietsch].

Graph 1 : the mechanisms of pressure agglomeration with the different stages reached and impact on the material

In some cases, the addition of a binder is required if compression of the bulk solids is only yielding weak bonding that do not give enough mechanical strength to the compact (tablet, briquette...) produced.

3. Tablet press working principle

How does a tablet press work ?

The compaction process in a tablet press machine is done following these steps :

- Die filling : the powder to compact flows from a hopper to the die

- Volume adjustment and Die scrapping : the lower punch is adjusted to measure the right volume of the compact and a scrapper is removing the excess of product

- Compaction : the upper and lower punch close and exert a high pressure on the powder, leading to compaction

- Punch release : the upper punch is lifted, no more compaction pressure is applied

- Tablet ejection : the lower punch is raised to remove the tablet which is then collected for further processing (typically packaging). The punch is then lowered to be ready for a new cycle

Figure 1 : working principle of a rotary punch and die press used for tabletting

These different actions can be done on a single punch and die press, for example for lab machines, or for compressing a large amount of materials, but the different components can also be arranged on a turret that allows to increase a lot the punching frequency, albeit with a small amount of material, as it is the case in pharma. The figure above is showing the working principle of a rotary punch and die press to produce tablets in pharmaceuticals or food supplement industries.

4. Factors influencing the choice and design of a tablet press

| Design factor |

What to be careful to |

| Production Volume and Speed | Assess the required production volume and speed to match the tablet press capacity with production needs. High-speed rotary presses are suitable for large-scale production, while single-punch machines may be adequate for smaller batches. |

| Tooling and Tool Material | Evaluate the tooling options and materials available for the press. The tooling's design, durability, and compatibility with the desired tablet characteristics are critical for successful tablet production. |

| Tablet Characteristics | Define the desired characteristics of the tablets, including size, shape, and hardness. Different tablet presses may excel in producing specific tablet attributes, influencing the choice of equipment. |

| Powder Characteristics | Consider the properties of the powder or granules being used. Factors like flowability, compressibility, and particle size distribution impact the compaction process and require matching with the press capabilities. |

| Integration with Downstream Processes | Evaluate how well the tablet press integrates with downstream processes, such as coating, packaging, or additional processing steps. Seamless integration enhances overall efficiency. |

| Regulatory Compliance | Ensure that the selected tablet press complies with industry regulations and standards, especially in pharmaceutical and food supplement applications. Manufacturers with a proven track record of adherence to regulatory requirements are preferable (see below). |

| Ease of Maintenance | Assess the ease of maintenance and availability of spare parts for the tablet press. Downtime for maintenance should be minimized, and quick access to replacement parts is essential for continuous operations. |

| Operator Training and User-Friendly Features | Consider the training requirements for operators and the presence of user-friendly features. Intuitive controls and clear documentation contribute to efficient operation and troubleshooting. |

Those considerations can be used as input for User Requirement Specifications when asking offers to suppliers.

5. Tablet press manufacturers

Tablet presses are found in major industries such as pharmaceuticals, food supplements or ceramics, thus many manufacturers have developed tablet presses to compete in this extensive market. The following tablet press manufacturers can be referred to :

- MYM machinery

- GEA

- Korsch

- Fette Compacting

When contacting a manufacturer, whether for a new or second hand

(used) tablet press, make sure to check its references and engage

in a detail conversation with the sales and technical staff to

understand the degree of knowledge of the vendor and how best he

will be able to support you when operating and maintaining the

press.

Source

[Pietsch] Agglomeration Processes (Phenomena, Technologies, Equipment), Pietsch, Wiley-VCH, 2004

[Perry] Perry's Chemical Engineer's Handbook, Section 21 Solid-Solid operations and processing, page 21-105, McGraw-Hill, 2008