Preblend - Premix

Why to preblend ? How to preblend ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Preblend and

Premix definition |

| 2. Why to preblend

? |

| 3. How to preblend ? |

| 4. Mixing quality required |

| 5. Carrier |

1. Preblend and Premix definition

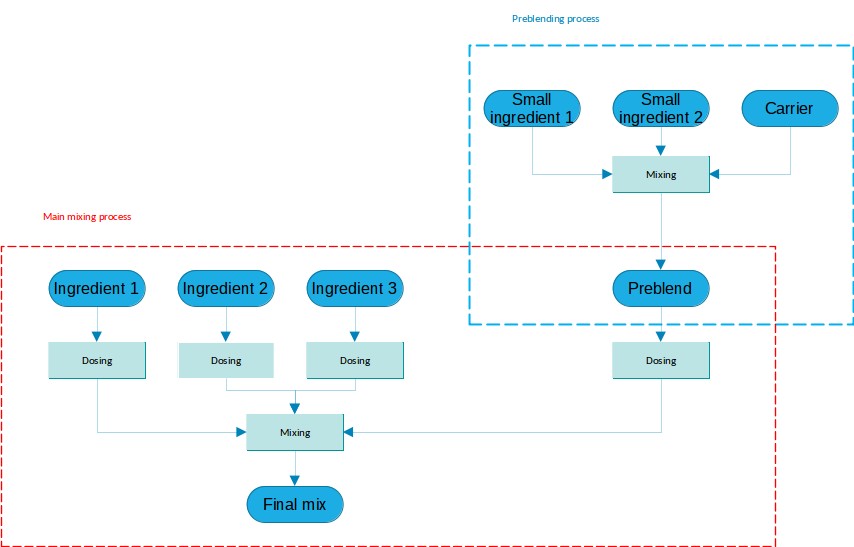

Preblend and premix are very widespread in the powder industry, many processes are actually using some of the materials required for the dry mix as preblend or premix.

A preblend, or premix, is made of several constituents that have been mixed together in advance. The resulting mix then becomes a single ingredient, the preblend or premix, when dosed to the final mixing step of a process. Preblend are typically made of one or several small ingredients mixed with a major ingredient, called the carrier.

The terms preblend and premix are often confused and used one for another. Sometimes the following distinction is made : a preblend will designate a mixture done on site by the same manufacturer of the final product while a premix will designate a mixture done by another supplier and bought by the manufacturer of the final product.

2. Why to preblend ?

Preblending is an additional process step which in appearance brings complexity. Why not simply mix all component together in a single mixer ?

There are actually 2 main reasons to decide to make a preblend or a premix :

- The number of ingredients is too important : instead of having, for example, 5 dosing system for small ingredients to the main mixer, a preblend is done so that only one dosing is required for the preblend

- The ingredient quantity per batch is too small and cannot be dosed reliably, or cannot be mixed efficiently : the preblend presents the advantage to dilute the small ingredients and make them easier to dose and then to disperse and mix. For example if a batch required 20 g of a component to be done automatically, it may be better to consider a preblend where it has been diluted 5 times so that 100 g of the preblend which contain 20 g of the component, is dosed.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

3. How to preblend ?

A preblend is done prior to the final mixing step. Many industrial setups can be found within the bulk solids industry, but the following are the most common :

- Manual process : if the quantity of process to produce and low, and safety allows to do so, ingredients are just manually pre-weighed and blended, typically in a rotating blender such a drum blender, V mixer or IBC blender. The product is then either conditioned in bags, and then re-tipped to the final process, or, in case of an IBC, the container is connected to the main process and discharged

- Automatic process : the preblending is then a kind of secondary mixing system directly in line with the main process. The ingredients are automatically dosed, mixed, and then transferred by gravity or through pneumatic conveying to a hopper from which the main process takes preblend when it needs it. Mixing quality of the preblend is not always very stringent so simple ribbon blenders are often used for such a process.

4. Mixing quality required

Preblend are to be dosed in a main mixing step, the homogeneity required for the preblend is therefore usually less stringent than the main mix requirements. The homogeneity target for the preblend will depend on the quantity finally dosed. The higher it is, the lower the mixing quality needs to be (or higher the CV target). It is understandable as, even if there are some in-homogeneity in the preblend, the larger portion of preblend is dosed, the more chance there is to have the right quantity of components in the quantity dosed.

5. Carrier

It is often necessary to dilute the small ingredients constituting the interesting part of the preblend by another constituent that will come in much larger quantity and will thus allow to have significant enough weight of preblend to be dosed in the final step. This larger constituent is called a carrier and can be, in the example of food industries, sugar, or any other components that is needed in large quantity in the formulation, which is easy to manipulate and has a relatively good flowability.