Dry Mixing of cement and sand

How to mix dry mortars ?

How to mix dry concrete ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction :

dry-mixing of mortar and concrete |

| 2. How to dry mix

cements and mortars ? |

| 3. Addition of

liquid |

1. Introduction : dry-mixing of mortar and concrete

Construction industry is not the typical industry where people would think bulk solids Process Engineering has a large stake ; but actually it has quite surprisingly a central piece when one reckons that concrete and mortars are actually mixtures of bulk solids.

Concrete is indeed a mixture of cement, sands and gravels (aggregate) and mortar a mixture of cement, sands and lime. Considering the large volumes involved in construction industry, it is required to industrialize the process to dry mix those components. It is important to find the right mixer to do so.

Note that, to be used, these solids mixture must be further mixed with water ; the mixers presented can be used to dry-mix only, but also can be used to add water in order to make the ready to use cement or mortar.2. How to dry mix cements and mortars ?

2.1 Single shaft mixers

Single shaft mixers used in cement industries are likable in design to the ribbon blenders used in other industries with often some additional paddles mounted on the arms supporting the ribbon. The key difference is that the construction materials of the mixer must strongly reinforced by wear linings to be able to handle the abrasion imposed by the rocks being mixed. They are typically available with mixing volumes of 500-2000 l, they are cheaper than other design but require more time for mixing.2.2 Double shaft mixers

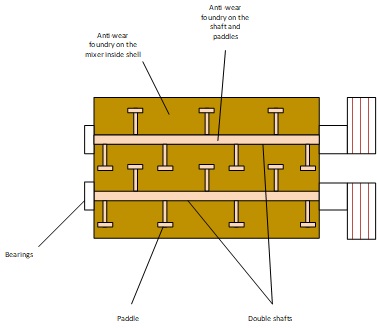

Those mixers have a design close to other double shaft mixers found in the industry. In this application however the mixing is done by convection rather than by fluidization.

Double shaft mixers are available up to 5-6 m3 in concrete industries (useful volume, which is typically 60-70% of total volume). Mixing time can range from 2 to 10 minutes depending on the material to homogenize. Big batches are however requiring large drives, up to 2*110 kW for a 6 m3 batch size. The inside must be lined with high resistance alloys (Ni-HARD for instance) in order to have a sufficient life span when handling very abrasive materials such as stones...etc...

Figure 1 : top view of double

shaft paddle mixer for concrete and cement mixing

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

2.3 Planetary mixers

Planetary mixers are inspired by the baking industry. They are made of several arms rotating under specific paths that allow to reach all the mixing area.

Planetary mixers can be as large as 3 m3 mixing volume. As for the other designs shared on this page, the inside must be designed to have a high resistance to abrasion.

2.4 Ploughshare mixers

Ploughshare

mixers can be adapted when having not only to make a

dry-mix, but also to add water in order to have the wet concrete

or wet mortar. This kind of mixer brings a lot of shear and thus

allows a good mixing of liquid and solids.

3. Addition of liquid

The mixers above can be used to perform only dry-mix, the mix of solids is then discharged, conditioned and brought to a construction site where it will have to be mixed with water. But manufacturers generally propose to have water addition directly in those mixers and thus directly produce wet mortar or concrete.

3.1 Deagglomerators

Deagglomerators are small agitators, usually fitted with blade shaped mixing tools and rotating at 1000-3000 rpm thus providing a lot of shear locally. They are always used as complement of the main agitator of the mixer on which they are mounted.

3.2 Cleaning in Place

Mixers in concrete industries can be fitted with water injection, spray balls / nozzles, in order to clean the mixer.

4. Suppliers of concrete and mortar mixers

The following companies can supply dry mixers for cement and mortar production :

- BHS Sonthofen