Batch Powder Mixer discharge time / emptying time

How to optimize emptying duration of a dry mixer

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Mixer discharge

time |

| 2. Powder mixer

discharge weight as a function of time |

| 3. Optimization discharge time for

batch powder mixer |

| 4. Order of magnitude discharge time

mixers |

1. Mixer discharge time definition

The discharging time of a bulk solids mixer is the time needed to empty it to the point it is ready for another batch. It is important to remark that the definition does not precise to "empty totally", indeed it is not always necessary to totally unload a mixer used in batch mode.

2. Powder mixer discharged weight as function of time

Graph 1 :Discharge time profile

The weight discharged increases sharply at the beginning of the discharge, but then follows an asymptote, thus the last kg to be removed from the mixer takes proportionally longer than the rest of the batch.

Note : the graph above is relevant for mixers having a discharge valve, flap or round. For mixers having bomb doors opening in the whole length of the mixer, the asymptote will not really exist.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

3. Optimization of discharge time batch powder mixers

How to unload faster ?

To optimize the cycle time, it can be interesting to decide to stop the discharge while few kg of product are still remaining in the mixer. If it is sufficiently low, it is likely that the remaining product will not affect the next mix homogeneity, but this will help to gain several seconds that will translate in additional capacity. The discharge can be governed according to a timer, but it is better to verify it through weight as well by having the discharge hopper or IBC on load cells.

The mixer should be run at low speed, below ATEX speed, to promote the discharge. An optimum is to be found as running too quick may in the contrary slow down the end of the discharge.

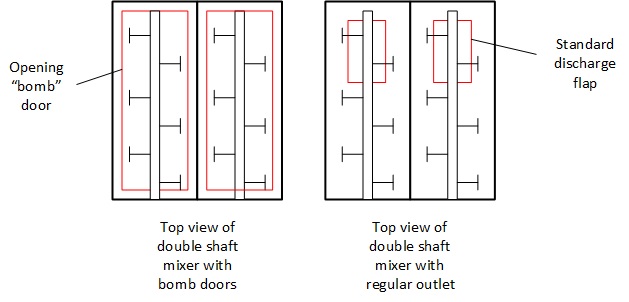

Bomb doors, which are discharge valves almost as long as the mixer body, will give the quicker discharge time, they are typically found on double shaft paddle mixers. For applications, or mixers, where bomb doors are not applicable, the discharging valve can be doubled, on both to allow more flow.

Figure 1 : comparison bomb doors

and regular discharging valves

4. Orders of magnitude discharge time mixers

How long it takes to discharge a solids blender ? Orders of magnitude for a 1000 l mixer

Table 1 : Usual discharge time

| Discharge type | Discharge time |

|---|---|

| Bomb doors | 20 s |

| Single flap / valve | 1-2 min |

| Double flap / valves | 45-60 s |