Product inlet in pneumatic conveying line

Valves / injectors / entrainment boxes

Question or remark ? Please contact us at admin@powderprocess.net| Section summary |

|---|

| 1. Introduction |

| 2. Dilute Phase - Pressure |

| 3. Dilute Phase - Vacuum |

| 4.Dense Phase - Pressure |

| 5.Dense Phase - Vacuum |

1. Introduction

The way to bring product in a pneumatic conveying line will be changing depending on the technology chosen. A dosing equipment or a valve may be required in some cases, not in others. The page is detailing how to chose the right product supply to a conveying line.

2. Dilute Phase - Pressure

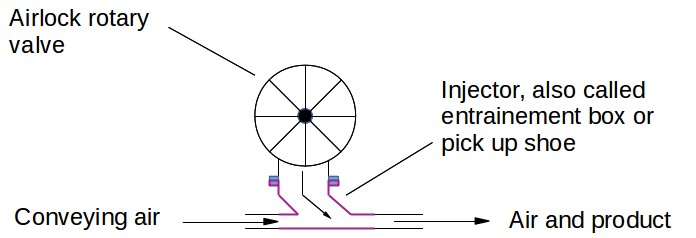

In pressure dilute phase, the bulk solids transported must be brought from an area of atmospheric pressure, in most of the cases, to a pressure at the beginning of the line which is around 400-500 mbar. It is therefore necessary to create a "sas" that is most of the time done by an airlock rotary valve. When having a drop through execution, the valve must be fitted with an entrainement box below which is helping the product fall in the direction of the air flow.

Figure 1 : Entrainement box or injector for dilute phase pressure conveying

For the blow through execution of the valve, as the conveying line goes directly through the star valve, there is no need of such a box.

3. Dilute Phase - Vacuum

In vacuum, there is no pressure drop to overcome when introducing the powder or bulk solids to the line, as the beginning of the line is always close to atmospheric pressure, thus a simple device to control the flow of solids - screw conveyor, butterfly valve... - is sufficient. To help the product flow in the right direction and not have choking of the line, an injector similar to the entrainment box above is often used.

4. Dense Phase - Pressure

In pressure dense phase, the materials to be conveyed is filled in a pressure tank. This tank is only equipped with a butterfly valve at the bottom that will be opened once the right level of pressure for the conveying is done. The outlet pipe of the tank has a bend shape to help the product enter the line. The bend and the pipe right after may be fitted with additional air injections to control the pneumatic transfer and the capacity of the line.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

-----------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

5. Dense Phase - Vacuum

In vacuum dense phase, the introduction of powder in the line is done thanks to a hopper whose outlet is, like for the pressure tank, bended which allows to introduce the powder in the right direction.

Note : especially in dilute phase, it is important to respect a certain length of straight pipe after the product pick-up, it allows to accelerate properly the product and give it enough energy before the 1st bend. Failing to do this may expose to reflux and then line blockage at the bend.