Dry Mixing : liquid addition during mixing

Why spraying liquid in a dry mixer ?

How to introduce liquid to a powder mixture ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction :

liquid addition to a dry-mixer |

| 2. How to add

liquid to a powder mixture ? |

| 3. Best mixers for

liquid addition / granulation |

1. Introduction : liquid addition to a dry-mixer

Mixing bulk solids is a very widespread operation in process industries. Several dry components are loaded in a specific sequence in a mixer, such as a paddle mixer, ribbon blender or even bin blender, and then mixed altogether for a certain amount of time. The resulting dry mixture is then used for further process steps, or can be packed and sold as such.

In a surprisingly high number of cases, though, manufacturers will not only use dry materials but will also inject a liquid in the mixer. The addition of liquid can be done for many purposes but is very often an enhancement to the dry mix formulation. The main reasons of injecting liquid during powder mixing are the following :

- Modify the solids properties, especially the flow properties by reaching a certain degree of agglomeration - liquids are indeed creating small liquid bridges in between particles, thus binding small particles to big one. We then speak of granulation or wet agglomeration, and the mixer is often called a granulator. Such granulation can be used to improve the flowability of the material by having larger particles and / or to reduce the risks of segregation in the next process steps

- Add a component, such as a flavor which has no equivalent in dry state, an aroma, or a coloring

It must be noted that the liquid addition is here small (from <1% weight to 8-10%), it is not the purpose in this page to make a slurry but rather granulate (increase particle sizes) or coat the dry powder, although some continuous dry-mixers are sometimes advertised by their manufacturers as being able to handle masses with up to 50% liquid addition.

The addition of liquid should be adjusted in term of flowrate, moment of injection in the mixing cycle, in order to avoid the formation of lumps. There are systems designed to make a paste but it is not the purpose of this page to describe them.

2. How to add liquid to a powder mixture ?

2.1 Liquid spraying

The interest of spraying is to be able to cover a large part of the mixer volume rather than concentrate all the liquid in a limited area, which will most probably create lumping. The spraying must not be too quick, an order of magnitude of spraying time being 20-30 s ; the spray nozzle must then be selected considering the spray shape (make sure to avoid hitting the wall of the mixer) and the capacity to have a sufficient spraying time.

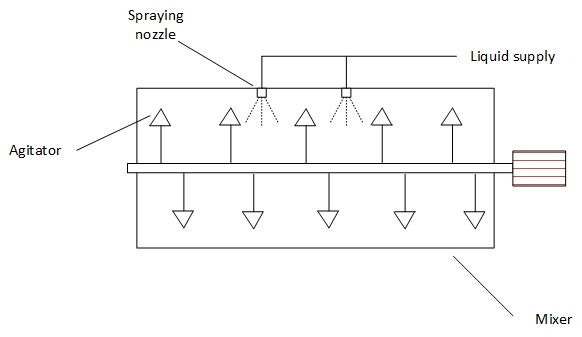

Figure 1 : example of a liquid spraying system in a high shear mixer

Single phase pressure spray nozzles are preferred rather than air

atomizing nozzles that may send too much liquid to the wall /

cover of the mixer. If the technology of the mixer allows it,

nozzles must be installed so that they spray in the fluidizing

area of the mixer (in between the shaft for a double shaft

paddle mixer for example) and should not be too close from the

powder mixture so that the droplets can form properly before

getting in contact with the powder.

2.2 Liquid injection

For higher proportions, the liquid may not be sprayed, but simply injected in the mixer. The point of injection must near a deagglomerator in order to avoid to create lumps of product while adding the liquid.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

2.3 Liquid metering

There are 2 main ways to dose the right amount of liquid to a mixer :

- Use a pump (positive displacement pump) and a flow meter (for low sensitivity cases, the dosing can be only volumetric based on the number of revolutions of the pump)

- Have a tank on load cells and use compressed air to pressurize the tank and push the liquid through the spraying nozzle

2.4 Pre-mixing

The addition of liquid, especially if it is quite viscous, may make the mixing difficult. It can then be interesting to have a pre-mixing time with only the dry ingredients prior to introducing the liquid, so that the dry ingredients are mixed with a certain homogeneity.

2.5 Addition time and wet mixing time

The batching system is often programmed in 2 stages when having to handle liquid [Kansas] :

- Liquid addition time during which the liquid is injected / sprayed

- Wet mix time during which the mixing is done after the liquid has been added

In order to optimize the cycle time, the liquid addition time is often programed to be as fast as possible. However, as fast as possible means that the flowrate of liquid must be increased, which can lead to the increase of the droplets of liquids, and then to lumping. A balance must then be found in between optimization of cycle time and risks to create clumps of product.

The wet mixing time must be sufficient in order to distribute properly the liquid and may have to be increased if the liquid addition time was too short. Experiences are required in order to define the optimal liquid addition and wet mix time. [Kansas] is also suggesting that the type of mixer has an influence on how the addition time will impact the homogeneity and thus total cycle time. For example, ribbon blenders were quite insensitive to the addition time (the shear forces applied by the ribbon may help to break the agglomerates), while it mattered for paddle mixers (a longer addition time may allow to benefit from the fluidizing effect of this kind of mixer). The paper from [Kansas] however highlights that it is difficult to define generalities and experience / validation must be performed on industrial mixers.

2.6 Use of vacuum

When having to spray some specific materials, and especially flavors in food industries, it can be interesting to actually put the powder under vacuum prior to the addition of liquids. The vacuum is then freeing the porosity of the powder of air, which is then improving the adsorption of the liquid sprayed and binding with the powder. The manufacturer may then add more liquid while keeping good powder properties (flowability especially) and having a good retention of the liquid in the powder.

3. Best mixers for liquid addition / granulation

It is difficult to define what is the best mixer when adding a small portion of liquid to a dry mixture, however mixers can be gathered in different groups according to the performances expected.

3.1 Bin blenders / V mixers

Free fall rotating mixers such as bin blenders and V mixers are sometime proposed by their manufacturer as suitable for the injection of liquid. If it is possible to add liquid, this kind of mixer is not optimal for such a service as the shear rate is very low, there is no fluidization of powder, which means that the injection of liquid will almost certainly lead to lumps and a bad homogenization of the liquid in the powder mixture. As a consequence, in order to improve the mixing, the injection of liquid must be done close to a deagglomerator or an intensifier bar for V mixers (high speed agitators providing shear and therefore breaking lumps). The deagglomerators have however the effect to increase the breakage (degradation) of the powder, all the more that mixing time may be long for these mixers.

3.2 Ribbon blenders

Ribbon blenders can be fitted with liquid injection / spraying systems. The liquid is sprayed on the surface of the mix, then a wet mixing time must be applied during which the ribbon will help breaking agglomerate and distribute the powder. This wet mixing time can be relatively long.

3.3 Double shaft paddle mixers

Double shaft paddle mixers are creating, during mixing, a

fluidized zone in between the mixing shafts. This fluidization

area can be used in order to optimize the spraying of materials

: spraying on the fluidize powder reduces the risks of lumping and

allows to reach a large part of the powder before even the wet

mixing time starts. If lumping is still observed, especially when

the quantity of liquid added is high, then deagglomerators can be

added to the mixer.

3.4 Shear mixers (ploughshare mixers)

This kind of mixers, thanks to the shape of the agitator but also

the speed of rotation of the shaft is well adapted to the

injection of liquid, and especially for high percentage of

liquid addition where the powder flowability properties are

strongly influenced (for example by injecting fats). The shear

provided by the mixer is indeed helping to break lumps and

homogenize the mixture ; the use of 1 or several deagglomerators

can complete the already good shearing effect of the main shaft.

Due to the shear, this type of mixer is usually achieving a short

mixing time but possibly with a strong breakage of the powder.

3.5 Deagglomerators

Deagglomerators are small agitators, usually fitted with blade

shaped mixing tools and rotating at 1000-3000 rpm thus

providing a lot of shear locally. They are always used as

complement of the main agitator of the mixer on which they are

mounted.

Source

[Kansas] Saensukjaroenphon, M.; Jones, C. K.; Fahrenholz, C. H.; and Stark, C. R. (2016) "The Effect of Liquid Application Times, and Mixer Types with Different Wet Mix Times on Uniformity of Mix," Kansas Agricultural Experiment Station Research Reports: Vol. 2: Iss. 8.