Hammer Mill Screens: Types, Design & Sizing Guide

Learn how to select, size, and optimize hammer mill screens for precise particle control and maximum milling efficiency

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction to

Hammer Mill Screens |

| 2. Types of Hammer

Mill Screens |

| 3. Design of

screens used in hammer mills |

| 4. Troubleshooting and Maintenance |

1. Introduction to Hammer Mill Screens

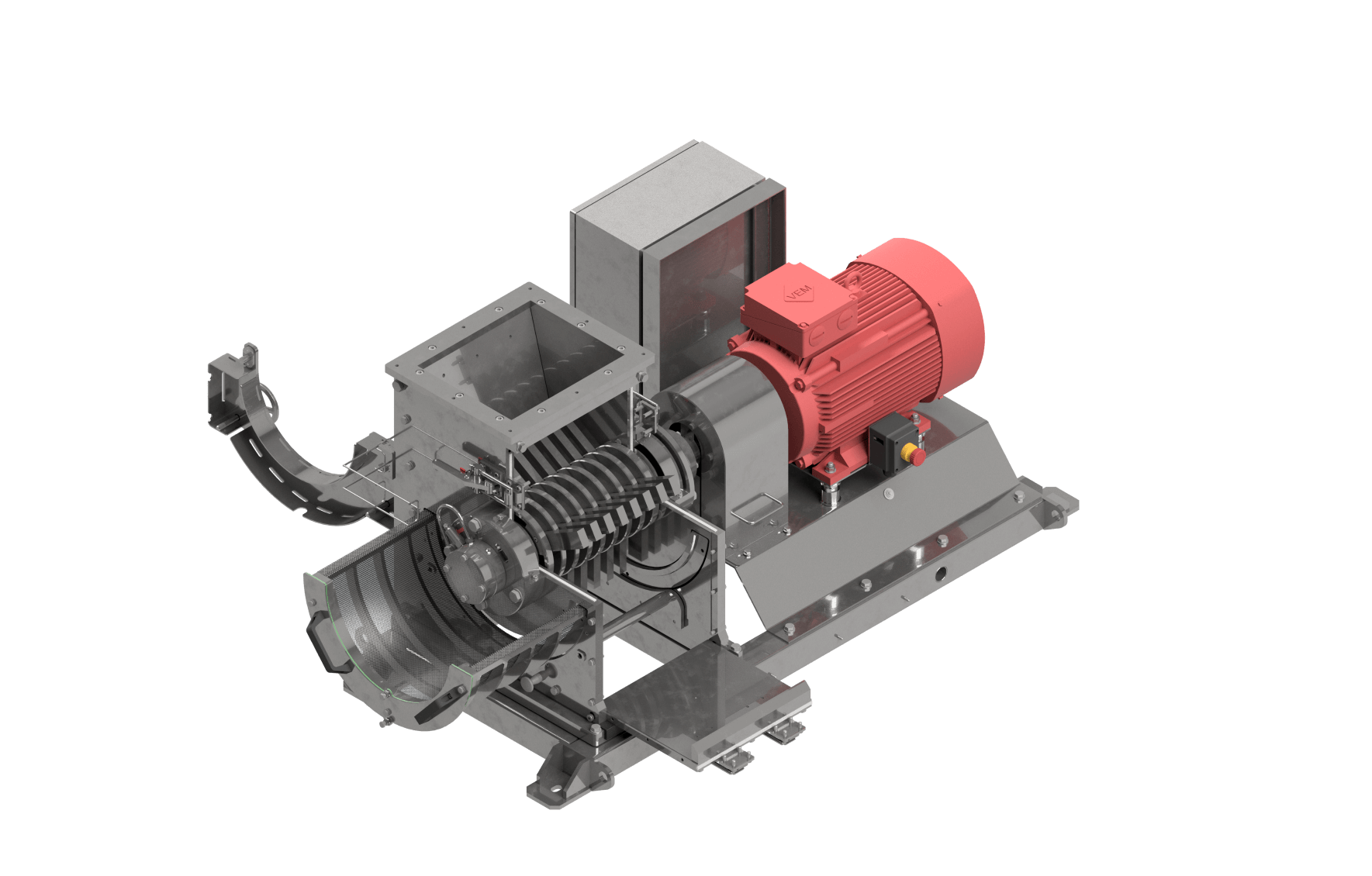

Hammer mills are critical components in the grinding and milling processes, widely used in industries such as agriculture, food processing, pharmaceuticals, and mining. Hammer mills are fitted with screens that control the particle size of the final product by allowing only particles smaller than the screen's holes to pass through. Understanding the different types of screens, their manufacturing processes, applications, and troubleshooting techniques is essential for optimizing mill performance and achieving the desired particle size distribution.

2. Types of Hammer Mill Screens

-

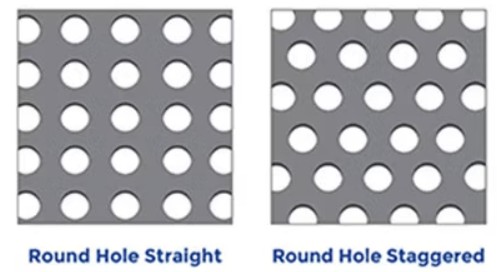

Round Hole Screens:

-

Design: These screens feature circular perforations arranged in rows, with holes in adjacent rows offset from one another.

-

Applications: Suitable for standard milling applications, particularly for free-flowing materials, granules, small lumps, and powders. They are commonly used in dry milling, blending, deagglomeration, and reducing the bulk density of spray-dried powders.

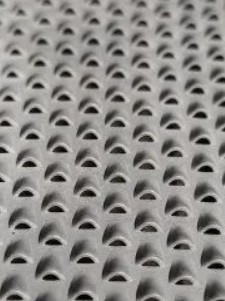

- Conidur Screens:

-

Design: Conidur screens have directional perforations that facilitate finer milling with reduced blinding. The surface of the screen is raised to create a rasp-like texture, which enhances the shearing action for breaking up the material.

-

Applications: Ideal for processing friable materials and achieving uniform particle sizes. They are particularly effective for milling hard materials that require more aggressive milling action, such as seeds, tablets, and sweets.

- Slotted or Herringbone Screens:

- Design: These screens are manufactured by stamping elongated holes into sheet steel. The pattern of slotted screens aligns the slots end to end in rows, with adjacent rows staggered from one another. Herringbone screens have holes that form angles to one another, with adjacent rows aligned.

- Applications: Suitable for sticky, high-moisture, and fibrous products due to the larger hole area. They are often used in wet milling applications.

3. Design of screens used in hammer mills

3.1 Manufacturing of Hammer Mill Screens

- Materials: Hammer mill screens are typically made from carbon steel or stainless steel. Carbon steel is commonly used for its durability, while stainless steel is preferred in applications requiring corrosion resistance or compliance with sanitary standards, such as in food and pharmaceutical industries.

- Process: The manufacturing process involves advanced techniques to ensure consistent open area percentages across screen designs. This includes adjusting the density of screen perforations and the spacing between them. The screens are often custom-made to fit specific milling equipment and applications.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

3.2 Screen Hole Sizes and Material Specifications

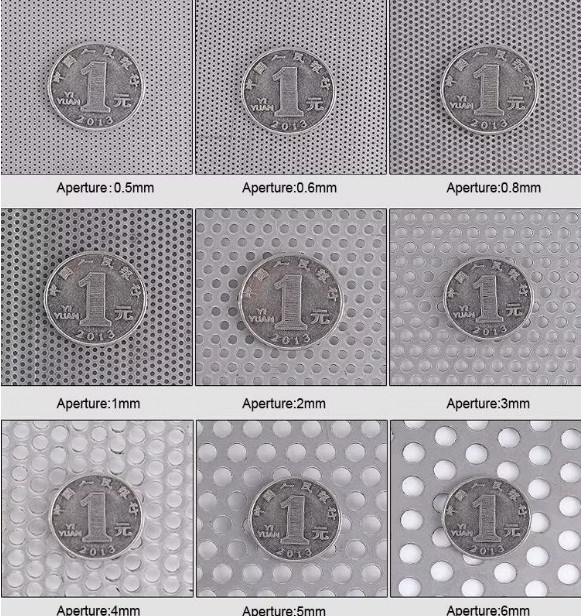

- Hole Size Ranges: The hole sizes for hammer mill screens typically range from 0.3mm to 10mm for carbon steel and 0.6mm to 5.0mm for stainless steel. However, the actual hole size selection should be based on the desired particle size distribution and the material's characteristics. For materials requiring finer particle sizes, smaller screen openings may be necessary, regardless of the screen material.

- Material Selection: The choice of material depends on the application. Carbon steel is commonly used for its durability, while stainless steel is preferred for corrosion resistance and sanitary applications.

Rule of thumb to determine the minimum hole size for a given application

[Malczewski] gives the following rule of thumb to estimate what is the hole size required to reach a target granulometry :

- For materials that can be grounded easily ("highly friable") : the hole size can be taken 8 to 10 times the largest desired particle. Sugar, salts and grains are in this category.

- For materials that have an average groundability ("average friability) : the hole size can be taken 5 to 8 times the largest desired particle. Resins, mineral, chemical, clay are in this category.

- For materials that are difficult to grind ("harder, less friability") : the hole size can be taken 2 to 5 times the largest desired particle. Wood, grain hull, shells and fibers are in this category.

These are only orders of magnitudes, typically to have a starting point, it is always recommended to have a set of screen sizes when making trials in order to be able to try and select the one that will give the best couple granulometry / mill capacity.

3.3 Open Area Percentage

- Typical Ranges: The open area percentage significantly influences the mill's throughput and efficiency. For round hole perforations, open areas typically range from 30% to 60%. Conidur screens, due to their design, have lower open areas, often between 10% and 20%.

- Impact on Performance: A higher open area allows for increased material flow through the screen, enhancing mill capacity. However, it may also lead to reduced screen strength and durability. Conversely, a lower open area can improve screen life but may decrease throughput. Balancing open area with structural integrity and desired particle size is crucial.

3.4 Screen Orientation and Edge Configuration

- Hole Orientation: Staggered hole patterns are effective in promoting uniform particle size distribution and reducing the likelihood of screen blinding. This design ensures that particles have multiple opportunities to pass through the screen openings.

- Edge Configuration: The orientation of the screen's sharp or burr edge can influence milling efficiency. Positioning the burr side facing the material flow can enhance cutting action, leading to finer particle sizes. However, this may also increase screen wear, necessitating more frequent maintenance.

4. Troubleshooting and Maintenance

- Clogging: Screen clogging can result from processing materials with high moisture content or those prone to agglomeration. Implementing proper pre-processing steps, such as drying or conditioning the material, can mitigate this issue.

- Wear and Tear: Regular inspection and timely replacement of worn screens are essential to maintain milling efficiency and product quality. Utilizing wear-resistant materials or coatings can extend screen life.

- Incorrect Screen Selection: Using the wrong type of screen for the material can lead to inefficient milling or poor particle size control. Ensuring the screen type and hole size match the material and desired particle size is crucial