Grinding power : step by step calculation

How to estimate the power required for a grinding mill ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Work-index |

| 2. Calculation of

the work-index |

| 3. Estimation of

the power consumption of a grinding mill |

| 4. Example : Step by step estimation of the power required for a grinding mill |

| 5. Free Excel calculation tool for estimating grinding mill power consumption |

Comminution (particle size reduction) is one of the industrial activities that is requiring the highest amount of energy worldwide, particularly through mining activities. Estimating the power required by a grinding mill is then particularly interesting for industrial looking to invest in a new grinding process in order to define the CAPEX and OPEX costs.

The calculations below mainly apply to ore mills.

1. Work-index

What is the work-index of a mill ?

The work-index is a parameter used in ore milling processes. It is defined as the energy needed to reduce ore from infinite size to the state where 80% of the milled ore will pass through a 100 mesh screen.

What is a mesh, how does it convert to micron ?

It is very common in milling application to refer to the size as per the "mesh" measurement. The correspondance mesh to microns is given below :

| US Mesh* | Microns | Inches | Millimeters |

|---|---|---|---|

| 35 | 500 | 0.0197 | 0.5 |

| 40 | 400 | 0.0165 | 0.4 |

| 45 | 354 | 0.0138 | 0.354 |

| 50 | 297 | 0.0117 | 0.297 |

| 60 | 250 | 0.0098 | 0.25 |

| 70 | 210 | 0.0083 | 0.21 |

| 80 | 177 | 0.007 | 0.177 |

| 100 | 149 | 0.0059 | 0.149 |

| 120 | 125 | 0.0049 | 0.125 |

| 140 | 105 | 0.0041 | 0.105 |

| 170 | 88 | 0.0035 | 0.088 |

| 200 | 74 | 0.0029 | 0.074 |

| 230 | 63 | 0.0025 | 0.063 |

| 270 | 53 | 0.0021 | 0.053 |

| 325 | 44 | 0.0017 | 0.044 |

| 400 | 37 | 0.0015 | 0.037 |

| 450 | 32 | 0.0013 | 0.032 |

| 500 | 25 | 0.0010 | 0.025 |

| 635 | 20 | 0.0008 | 0.020 |

2. Calculation of the work-index

2.1 STEP 1 : Gather the data

In order to calculate the work index for a particular material in a mill, it is necessary to carry out a grindability test :

- Get a sample of the material to grind

- Select the mesh P1 at which the material is to be grinded during the test : for example 200 mesh (= 75 microns)

- Measure the 80% passing size F (microns) for the feed

- Run the test and measure the Bond grindability G in g/rev of the mill

- Measure the 80% passing size P (microns) for the product

2.2 STEP 2 : Calculate the work index

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

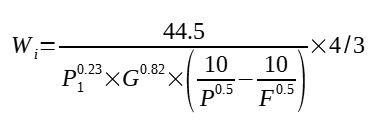

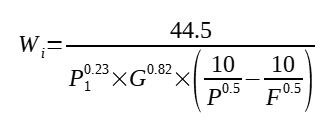

Wet milling [Chopey]

Wi = 44.5/[P10.23*G0.82*(10/P0.5-10/F0.5)]

Dry milling [Chopey]

Wi = 44.5/[P10.23*G0.82*(10/P0.5-10/F0.5)] *4/3

With :

Wi = work index (kWh/t)

P1 = size of the mesh of grind of the grindability test (microns)

F = 80% passing size of the feed to the grindability test

(microns)

P = 80% passing size of the result of the grindability test

(microns)

3. Estimation of the power consumption of a grinding mill

3.1 STEP 3 : Estimate the power consumption of a grinding mill for a particular application

The Bond 3rd theory of comminution is estimating the power required to mill a particular ore thanks to the following formula [Chopey] :

W = 10*Wi*(P-0.5-F-0.5)

With :

W = Power consumption of the mill (kWh/t)

Wi = work index (kWh/t)

F = 80% passing size of the feed to the mill (microns)

P = Required 80% passing size of the milled product (microns)

F and P are different than on those of the grindability test

4. Example : Step by step estimation of the power required for a grinding mill

A mining company is investing in a new line of production of an ore. The material must be sold as fine powder, with 80% of the material passing through a 80 microns mesh. The feed material is however much bigger since 80% of the feed 8passes through a 2000 microns mesh.

What is the estimated power required to run the mill ? The milling is done Dry.

4.1 STEP 1 : Gather data

In order to gather the necessary data to size the mill, the company is running 1st a grindability test. The results are the following :

- The material is grinded at a mesh P1 of 200 mesh (= 75 microns)

- Measure the 80% passing size F (microns) for the feed = 2000 microns

- Run the test and measure the Bond grindability G in g/rev of the mill = 2.5 g/rev

- Measure the 80% passing size P (microns) for the product = 42 microns

4.2 STEP 2 : Calculate the Work-Index

The work index is calculated thanks to the following formula :

Wi = 44.5/[P10.23*G0.82*(10/P0.5-10/F0.5)] *4/3= 44.5/[750.23*2.50.82*(10/420.5-10/20000.5)]*4/3 = 7.86 kWh/t

4.3 STEP 3 : Estimate the power required for the particular application

W = 10*Wi*(P-0.5-F-0.5) = 10*7.86*(80-0.5-2000-0.5) = 7.03 kWh/t

5. Free Excel calculation tool for

estimating grinding mill power consumption

The required power consumption of a grinding mill based on the

calculations shown above can be estimated thanks to this free

Excel calculator : Calculation Tool - Grinding Mill Power

Calculation

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. Please consult a reputable designer for all detail design you may need.

Source