Cartridges filters for dust : design, materials, filter size

calculation

What is a cartridge filter ?

How to chose the material of your cartridge filter ?

How to size gas solid filtration systems with cartridges ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Cartridges

filters : design |

| 2. Cartridges

filters materials |

| 3. Cartridges

filters : required filtration area calculation, filter

sizing |

When it comes to dedusting a gas stream, cartridges filters can have strong advantages compared to conventional bag filters, especially in terms of filtration area in a reduced volume. This page is helping you to understand how are made cartridges filters and how to size a filtration system with cartridges.

1. Cartridges filters : design

What is a cartridge filter ?

Contrary to bag filters, which have the aspect of a flexible cloth and are mounted on a cage to give them their shape, cartridges filters take the form of rigid pleated cartridges. The filtering media is arranged in pleates that allow to reach a higher filtration area than bag filters in the same volume.

What is the difference between cartridge filters and bag filters ?

Cartridges filters have the following pros and cons compared to bag filters.

Pros of cartridges filters vs bag filters

- Higher filtration area within the same volume, thus possibility to have a smaller dust collector

- Easy mounting and dismounting of the cartridges, gain in maintenance time

- Better filtration efficiency

- Longer life time if used properly

Cons of cartridges filters vs bag filters

- Higher unitary costs

- Risks of clogging in between each pleat with sticky materials

The cartridges are hollow which allows the air to get through the filter media but also helps in cleaning the cartridge by sending the pulsing air within the filter body. The end cap of the cartridge is however not made of filtration material and therefore represent a "lost" surface both for filtration but also for cleaning efficiency as the cleaning air cannot go through it.

New designs have however been introduced recently where the end cap of the filter is replaced by an internal cone which has the double advantage to extend the filtration area while improving the cleaning efficiency of the air pulse.

2. Cartridges filters materials

How many types of cartridge filters are there ?

The following materials are commonly used for cartridges filters :

- Cellulose blends

- Spunbonded polyester

Cellulose blends (cellulose + polyester) are the simpler and less expensive materials but they offer relatively low performance compared to polyester which tends to be more and the base material for these cartridges. Spunbonded polyester provided better filtration, less pressure drop, cleans easier with a pulse jet system and is more durable.

Those 2 medias are providing a filtration by having the dust penetrating the material, which creates high pressure drop.

The basic polyester matrix can be enhanced further by applying a layer of special material which allows to keep the dust at the surface and thus avoid deep penetration in the material :

-

Nanofibers : a very thin layer (<1 micron) of nanofibers (<0.3 micron) is applied on the supporting materials. This allows to prevent smaller dust to penetrate deeply in the catridge and plug it. As a consequence it also helps the cleaning of the filter.

- Meltblown lamination : a thermoplastic is molten and blown onto the supporting material. It enhances the filtration efficiency but some dust can penetrate deep in the meltblown laminate which can makes it difficult to clean.

-

ePTFE : A PTFE membrane can be easily applied on the surface of cartridges. The membrane allows better filtration efficiency while reducing the adherence of particles and thus promoting an efficient cleaning. The performances are similar to nanofibers but allow to reach a higher efficiency, in consequence the cost is as well higher than nanofibers treatments.

The density of the pleats is also to be considered when selecting a cartridge filter. Indeed it is tempting to increase the number of pleats to increase the filtration area. However this can lead to issues as dust will accumulate easier in between pleats which will significantly decrease the actual filtration surface area, a balance must then been found, which depends highly on the material processed.

Additionally, it is interesting, if the pleat density is high, to consider design of cartridges with spacers that prevent the pleats to contact and close the gap in between them. The spacers can be external or in the inside of the cartridge.

Some other options are available such as flame retardants filter medias.

3. Cartridges filters : required filtration area calculation, filter sizing

Cartridge filter sizing : how to size a cartridge filter system ?

When designing a dust collector using cartridges filters, the following design sizing criteria must be studied : air to cloth ratio (filtration velocity), intersticial velocity and can velocity.

3.1 Air to Cloth ratio for filter cartridges

The air to cloth ratio is actually similar to the air filtration velocity calculated by dividing the volumetric air flow at the inlet of the dust collector, by the total filtration area installed.

Air_To_Cloth_Ratio = Qair/Sfilter_effective

with :

Qair = total air flow at the inlet of the baghouse

(m3/s)

Sfilter_effective = actual filter surface available

(m2)

In US, the same calculation is done but with cfm and ft2 which gives an air to cloth ratio in ft/min, it is important to know in which units the ratio is expressed as the values

For bag filters, literature references mention filtration velocities up to 0.06-0.07 m/s, but filtration velocities in filter cartridges are typically lower, in the range of 0.025 m/s, sometimes 3 times lower bag filters. 0.025 m/s is good for a 1st approximation but more precise values can be obtained from manufacturers' data.

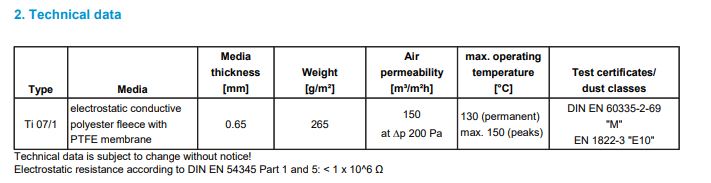

Example : the following data are given by a cartridges manufacturer

The manufacturer gives a permeability of 150 m3/m2h,

which means a filtration velocity or air to cloth ratio of 150 m/h

= 0.0416 m/s which appears slightly higher than the value given

above.

The air to media ratio is the most common design criteria discussed for filters. However, for pulse jet systems where the cartdriges are vertically mounted and the inlet of dust laden air below the cartridges, the air velocity below, and in between the filters, should not be neglected as. If it is too high, it will prevent the dust unclogged from the filters during a compressed air pulse, to fall down. The air going upwards will indeed immediately re-entrain the powder which will make the pulse jet cleaning ineffective.

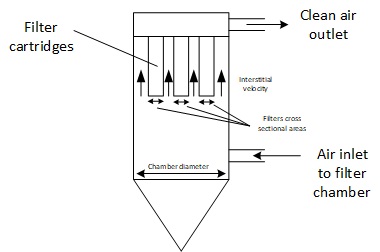

3.2 Can velocity

The can velocity is defined as the volumetric air flow divided by the cross sectional area of the filtration chamber.

Can_Velocity = Qair/Schamber

With :

Qair = total air flow at the inlet of the baghouse (m3/s)

Schamber = cross sectional area of the filter chamber

(m2)

3.3 Intersticial velocity

The intersticial velocity is the velocity in between the filter, which means that it is defined by the volumetric air flow divided by (the cross sectional area of the chamber - the sum of the cross sectional areas of the filters)

Interstitial_Velocity = Qair/(Schamber-Ssection_filters)

With :

Qair = total air flow at the inlet of the baghouse (m3/s)Schamber = cross sectional area of the filter chamber (m2)

Ssection_filters = sum of the cross sectional areas of the filters

3.4 One more criteria

[Kenchin] in an article is proposing one more criteria for cartridge filters, it is the filter-periphery air flow velocity. Indeed the filtration velocity (air to cloth ratio) is calculated on the entire filtration area of the cartridges, which includes all the pleates. However, the "enveloppe" of the filter has a much lower area than when the pleates surfaces are considered which means that the air velocity, when it approaches the cartridges will have a much higher velocity. For certain dusts, the filter-periphery air flow velocity may be too high to allow them to fall down from the filter, which prevents an efficient cleaning.

Periphery_Velocity = Qair/[ncartridge*(Speriphery)]

With :

Qair = total air flow at the inlet of the baghouse (m3/s)ncartridge = number of cartridges in the filtration chamber

Speriphery = surface of the enveloppe of the filter cartridge (m2)

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

Source

[Kenchin] Designing a cartridge dust collector for better

filter cleaning and reliable performance, Kenchin, PBE