Combination scale : design guide

What is a combination scale ?

How does a combination scale works ?

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction |

| 2. Combination

scale components |

| 3. Principle of working of a combination scale |

| 4. Sizing a new combination scale |

| 5. Combination scales special designs |

| 6. Troubleshooting combination scales |

| 7. Buying a combination scale |

1. Introduction

The importance of weighing

Filling machines are used to fill and pack a very precise amount of material that will be sold. Ensuring that the weight is as precise as possible is critical for the business as it will help to make the production profitable (do not overfill and sell "for free"), the product performance as per the consumer expectation (for example instant beverages must have the right quantity of powder to get a good reconstitution) and the compliance vs the regulation (do not sell less than what is indicated).

Some filling machines are equipped with their own dosing system, for example an Auger (or several Auger) that will volumetrically fill a defined amount of material. Some other machines are not directly equipped with such a dosing system and it is thus necessary to perform this function prior to the filler to make sure that the filling machine gets the right amount to fill.

One way to do this is to have a system of scales that will weight the material to fill and will then drop it to the filling machine. One of the design that became prominent is what is called a combination scale. This technical article aims at explaining what is a combination scale and how it works.

2. Combination scale components

Combination scales, also called multihead weighers, have been named this way because they are going to dose incremental amount of material in small hoppers, then are going to use a combination of those small hoppers with pre-weighed materials to achieve a larger target weight.

A general design has now been widely adopted by manufacturers although some details and options may vary from one supplier to another.

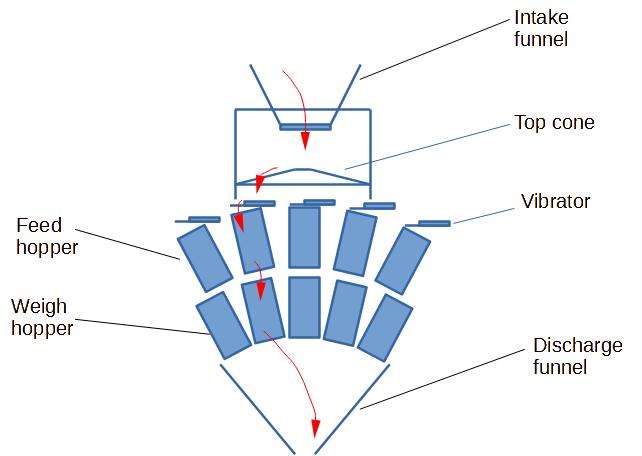

Combination scales are made of the following components :

-

An infeed funnel

-

A top cone

-

Linear vibrators

-

Feed hoppers

-

Weigh hoppers

-

Discharge chute

-

Collating funnel

2.1 Infeed Funnel

The infeed funnel serves as the initial point for material entry into the combination scale. Positioned at the beginning of the dosing process, it receives materials from an upstream process, typically through a feeder like a screw conveyor or vibrating tray. The infeed funnel directs the material flow toward subsequent components, initiating the precise dosing sequence.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

2.2 Top Cone

The top cone plays a crucial role in ensuring uniform material distribution across the combination scale. Positioned above the linear vibrators, the top cone employs sophisticated geometries to spread the material evenly. This even spreading is essential for the accurate dosing process, as it influences the amount of material allocated to each feed hopper.

2.3 Linear Vibrators

Linear vibrators are strategically arranged around the top cone and are responsible for the controlled dosing of material into individual feed hoppers. These vibrators use advanced vibration technology to regulate the flow of material, ensuring consistency and accuracy. The precise coordination of linear vibrators contributes to the effectiveness of the combination scale in achieving the desired target weights.

2.4 Feed Hoppers

Positioned below the linear vibrators, feed hoppers collect the dispensed material in discrete amounts. Each feed hopper corresponds to a specific linear vibrator, and their arrangement allows for the measured collection of material before it progresses to the subsequent weighing stage. The material in the feed hoppers is then transferred to weigh hoppers for precise weight measurement.

Multihead weighers are typically equipped with 10 to 24 (or even 32) small hoppers. The more hoppers the quicker will be the machine to weigh (of course the more it will take space and the more it will cost).

2.5 Weigh Hoppers

Weigh hoppers are equipped with load cells that enable accurate and real-time weight measurement of the material they contain. The combination scale's control system adjusts the vibration and feed bucket closure to achieve the desired target weight in each weigh hopper. The cumulative weights from multiple weigh hoppers are intelligently combined to meet the overall target weight.

2.6 Discharge Chute

The discharge chute serves as the conduit for the material once it has been accurately weighed in the combination of weigh hoppers. Selected based on the combination that achieves the closest match to the target weight, the weigh hoppers open, allowing the material to flow down the discharge chute. This controlled discharge ensures a precise transfer of material to the downstream processes.

2.7 Collating Funnel

The collating funnel is positioned at the end of the combination scale and serves as a temporary storage and buffering system. Equipped with actuated jaws, the collating funnel manages the flow of material, waiting for the downstream filling machine to request the product. This intelligent buffering ensures a smooth and uninterrupted production flow, enhancing the overall efficiency of the filling process.

3. Principle of working of a combination scale

The scale must be supplied in materials from an upstream process, typically a hopper equipped with a feeder such as a screw conveyor or a vibrating tray. The feeder will dispense material to the infeed funnel of the combination scale, the product to dose will then reach a top cone whose function is to spread the material evenly on top of the combination scale machine.

Spreading evenly the material is critical as a set of vibrating feeder, disposed in circle around the top cone, must then dose the material to hoppers located below each of the linear vibrators.

The material to dose is falling from each feeder to a feed bucket, and then to a weigh hopper which is on load cells. The control system of the combination scale is adjusting the vibration and the closing of the feed bucket to try to reach the desired target weight on the weigh hopper.

However it is important to understand that the target weight in a single weigh hopper is not the target weight to be filled. Indeed, the machine is spreading the total weight over several buckets. For example if the machine needs to weight a total of 100 g, maybe it will target 25 g / bucket. Then the machine will combine several of weight bucket to reach the target fill weight.

Example : if the machine has 14 weigh buckets, at a given time 6 of them are ready to discharge, with the following weights in grams 22.5 ; 27 ; 25 ; 22 ; 21 ; 24.5

The machine will check which hoppers to select to reach as close as possible as 100 g, for instance here 24.5+25+27+22.5 = 99 g

Once the machine has selected the hoppers to use, it will open them, the material will fall in the discharge chute and then the collating funnel. The collating funnel can be equipped with actuated jaws to buffer the amount of material and wait for the filling machine downstream to request the product.

4. Sizing a new combination scale

The sizing of a new combination scale will depend on the following factors :

- The product to be dosed : flowability, stickiness, bulk density

- The amount of material to be dosed

- The speed of the filling machine

- The accuracy to reach

4.1 Product to be dosed

It is very important to understand the product to be dosed, is relatively fine (if it is too fine and dusty, combination scales which are open system will probably not be the right choice), more granular which will be more favorable for combination scales. Is it sticky, oily ? in this case specific finishes such as dimpled surfaces. Such properties may also affect the shape of the feed and weigh hoppers to improve cleanability (Polygon-shaped buckets or rounded corners are easier to clean). What is the bulk density, on which the size of the bucket and the number of buckets to activate to reach the target weight.

4.2 Amount of material to be dosed

The amount to be dosed is dependent on the filling machine that is located downstream the combination scale. It is important to define the range of filling weight, as well as the corresponding range of bulk density of the products to be filled.

4.3 Speed of the filling machine

The combination scale must be able to supply product whenever a bag, sachet, stick... is ready at the filling machine. Machines processing small packaging weight can be very fast, up to 100 pack per min, the scale must therefore be designed in consequence, have for example different stages (feed hopper, weigh hopper, collating funnel) that can buffer several loads and improve the cycle time.

4.4 Accuracy to reach

The accuracy cannot really be set independently of the design parameters above, actually increasing the speed will most probably lead to a lower accuracy, having smaller weight will also lead to a larger relative error, the characteristics of the product will also impact strongly the accuracy, for example if a granular product is filled, maybe the accuracy will be dependent on whether a piece is falling or not at the end of the dosing.

In addition to the accuracy, it is also important to understand the process capability of the machine. For instance the supplier may say is 1.5 g but is it at 1 sigma, 2 sigma, 3 sigma... this needs to be clarified with the supplier.

5. Combination scales special designs

Suppliers can propose some specific design to cater with very special needs in factories.

5.1 Co-Dosing, Mixing

We have assumed so far that multihead weigher can process only one type of material at a time. It is not necessarily true, it is indeed possible to feed with 2 or even 4 products the scale and program a specific weight for each of the ingredients. The machine buckets are split in 2 to 4 zones and will weight in parallel each of the components, then will drop together the ingredients, allowing to have 2-4 components in the pack.

This solution requires a more complex upstream as the scale must be fed continuously from different hoppers (one for each ingredient). The more there will be ingredients, the larger will have to be the multihead weigher, especially if the speed to reach is high.

This can be a solution to avoid a complete mixing line if the recipes are relatively simple.

5.2 Multipoint discharge

It is also possible to have not one but several outlets for the combination scale. Each outlet is connected to a defined number of weighing hoppers that will weight the required amount and discharge it. This leads to an increase in the number of weight buckets to make sure there is still enough per outlet so that it can run as a combination scale.

5.3 Wet cleaning

Some applications may require that the scale is washed down. It is possible provided it has been taken into consideration in the design : tight system with high IP rating, hygienic design to have self draining surfaces that will accelerate drying.

6. Troubleshooting combination scales

| Challenges and Limitations | Description |

|---|---|

| Material Characteristics | Variability in particle size or density can impact weighing accuracy. |

| System Calibration | Regular maintenance and recalibration are required to prevent calibration drift. |

| Speed and Throughput | High-speed production may challenge accuracy, requiring adaptation to rapid material flow. |

| Material Sticking | Materials with high adhesive properties may stick to feed hopper surfaces, affecting dosing accuracy. |

| Vibration Issues | Precise vibration calibration is crucial to avoid variations in material flow and dosing inaccuracies. |

| Maintenance Requirements | Mechanical components may experience wear and tear, necessitating regular maintenance. |

| Integration Challenges | Ensuring compatibility with upstream and downstream processes is vital for system efficiency. |

| Complex Control Systems | Programming complexity may pose challenges during setup, requiring trained personnel. |

| Environmental Factors | Variations in temperature and humidity can impact the performance of sensitive components. |

| Material Cross-Contamination | Complete discharge from weigh hoppers is crucial to prevent cross-contamination between materials. |

| Product Changeovers | Changing products may require adjustments and recalibration, leading to downtime. |

| Limited to Free-Flowing Materials | Combination scales may be better suited for free-flowing materials, posing challenges with cohesive or non-free-flowing materials. |

7. Buying a combination scale

7.1 2nd hand combination scales

When buying a second-hand combination scale, several factors should be considered to ensure the right purchase. Here are some important factors to take into account:

- Use of the Scale : Determine the specific application and features you require. For instance, consider if the scale will be used for weighing large packages in a distribution center or for other specific purposes.

- Location in the Industrial Environment : Consider where the scale will be used to ensure it is suitable for that environment.

- Capacity : Evaluate the maximum weight the scale needs to handle to determine the appropriate capacity.

- Accuracy : Assess the level of accuracy required for your operations and ensure that the second-hand scale meets those requirements.

- Brand and Price : These are important factors influencing the purchase of second-hand products. Consider the reputation of the brand and the price of the second-hand combination scale.

- Risk : Evaluate any potential risks associated with the second-hand purchase, such as the condition of the equipment and the reliability of the seller.

- Maintenance and Support : Consider the availability of maintenance services and technical support for the specific second-hand combination scale you are considering.

These factors will help in making an informed decision when purchasing a second-hand combination scale, ensuring that it meets your operational requirements and provides value for your investment.

7.2 Combination scales suppliers

- Bilwinco

- Combi

- Ishida

- Multipond

- Parsons Eagle

- Yamato

Note that powderprocess.net has no relation with those companies.