NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Plate Heat Exchangers design : Pressure drop calculation

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. Plate heat

exchangers definition |

| 2. Calculation

procedure |

1. Pressure drop in plate heat exchanger

How big is the pressure drop in a plate heat exchanger ?

Plate heat exchangers are very efficient equipments to exchange heat. This comes from the fact that the fluid flows in narrow channels in between plates and with a certain degree of turbulence that can be helped through the design of the plate.

This has however a major drawback which is the pressure drop required to "push" the products through these channels and with this level of turbulence. The pressure drop generated by plate heat exchangers is therefore a key design criteria for plate heat exchangers. Before starting the design of an exchanger, the Engineer should know what is the pressure drop that can be afforded in the heat exchanger.

The method presented is simplified and gives an idea of the order of magnitude of pressure drop, it should not be used for detail design and construction of an equipment where the support of a specialized company must be sought.

2. Calculation procedure

How to calculate the pressure drop through a plate heat exchanger ?

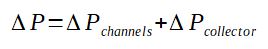

The pressure drop in a plate heat exchanger can be estimated thanks to the following correlation :

With

ΔP = Pressure drop through the exchanger, per side

(Pa)

ΔPchannel = Pressure drop through the exchanger

channels, in between each plate (Pa)

ΔPcollector = Pressure drop in the inlet/outlet ports

of the heat exchanger (Pa)

It has to be calculated on cold and hot side, as the value can be different.

2.1 Calculation of pressure drop in between plates

The pressure drop in a plate heat exchanger can be estimated thanks to the following correlation :

With

ΔPchannel = Pressure drop through the exchanger channels, in between each plate (Pa)f = friction factor (-)

ρ = density of the fluid (kg/m3)

u = velocity of the fluid in between 2 plates (m/s)

Dh = hydraulic diameter = [4*l*dplate] / [2*(l+dplate)] (m)

l = width of the plates (m)

dplate = gap in between 2 plates (m)

L = plate length (m)

The friction factor is calculated according to the following correlations, depending on the Reynolds and on the corrugation of the plates.

Some correlations are given below [Neagu] :

Correlation of Mulley which is taking into account the corrugation angle α :

The correlation of Kumar is also quite popular, as a function of the Reynolds [Neagu] :

- f=19.4*Re-0.589 for 10<Re<100

- f=2.990*Re-0.183 for Re>400

Re = Reynolds number (-) = ρ.u.Dh/μ

μ = viscosity of the fluid (Pa.s)

ρ = density of the fluid (kg/m3)

u = velocity of the fluid in between 2 plates (m/s)

Dh = hydraulic diameter = [4*l*dplate] /

[2*(l+dplate)] (m)

l = width of the plates (m)

dplate = gap in between 2 plates (m)

2.2 Calculation of pressure drop in the inlet and outlet collectors

It is also necessary to take into account the pressure drop in the manifolds at inlet and outlet (often low compared to the pressure drop inside the exchanger however). [Neagu] is giving the following formula to determine the collectors :

It needs to be calculated on both sides and added to the corresponding main pressure drop.

With (either for cold or hot sides)

ΔPcollector = Pressure drop in the inlet/outlet

ports of the heat exchanger (Pa)

m = mass flow of either cold or hot fluid (kg/s)

Np = number of passes

Dcollector = diameter of the collector on the side

considered (m)

μ = viscosity of the fluid (Pa.s)

ρ = density of the fluid (kg/m3)