NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Shell - Tube Heat Exchanger : calculation of correction

coefficients of Bell-Delaware method

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. Correction

coefficients applied in Bell-Delaware method |

| 2. Calculation of

correction coefficients of the Bell-Delaware method |

| 3. Calculation of the heat transfer coefficient on the shell side of a shell tube heat exchanger |

1. Correction coefficients applied in Bell-Delaware method

The Bell-Delaware method allows to calculate the heat transfer coefficient of a Shell-Tube heat exchanger on the shell side. It is based on the application of correction coefficients to an ideal heat transfer coefficient on the shell side. Those coefficients are the following :

- kch = correction factor for baffle cut

- kF = correction factor for baffle leakage effects - accounts for streams A and E

- kBP = correction factor for bundle bypass flow - accounts for streams C and F

- kRE = correction factor in laminar flow

This page is detailing how to calculate each correction coefficient.

2. Calculation of correction coefficients of the Bell-Delaware

method

2.1 kch correction factor for baffle cut

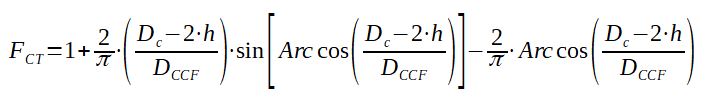

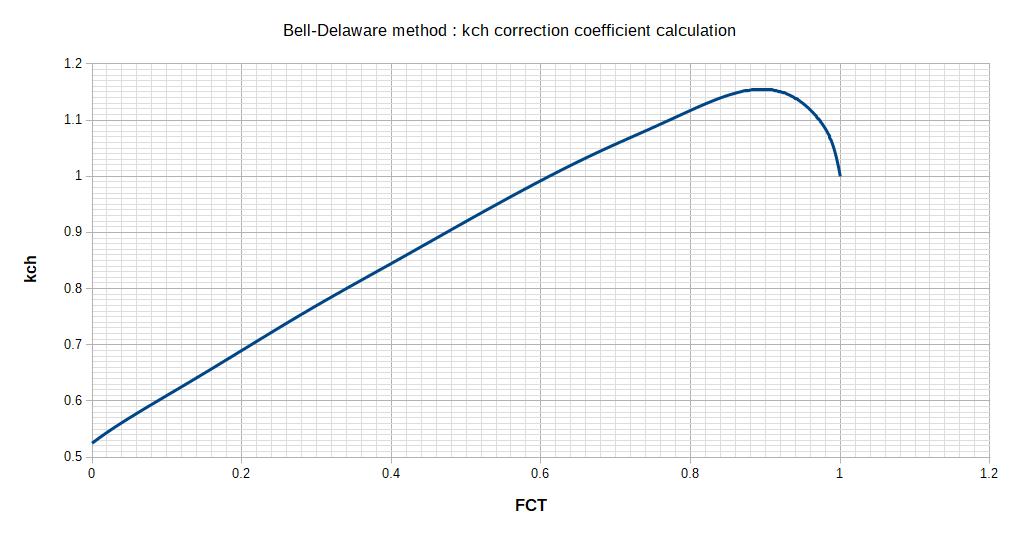

This correction factor is depending on the number of tubes that are located in cross flow (means they are covered by the baffle and the flow is forced through them). The factor FCT is then representing the fraction of the number of tubes in cross flow over the total number of tubes.

With :

DC = Shell diameter (m)

DCCF = tube bundle diameter (from most external tubes)

(m)

h = baffle cut (m)

The value of FCT is then used with the following Abacus to calculate kch :

2.2 kF correction factor

kF is accounting for leakages due to the bypass of the baffles. The flow can leak through the space around the baffle, or through the space in between the tubes and the baffles.

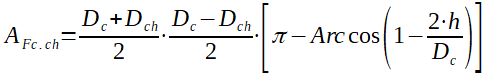

2.2.1 Leakage area AFC.ch in between the shell and the baffle

With :

DC = Shell diameter (m)

DCCF = tube bundle diameter (from most external tubes)

(m)

h = baffle cut (m)

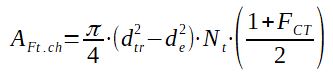

2.2.2 Leakage area AFt.ch in between the tubes and the baffle

With :

de = tube outside diameter (m)

dtr = baffle hole diameter (m)

FCT as calculated in paragraph 2.1

2.2.3 Calculation of the total leakage area

The total leakage area is the sum of the leakage in between the baffle and the shell, and in between the baffle and the tubes.

AF=AFc.ch + AFt.ch

2.2.4 Calculation of kF

kF is determined according to the following abacus :

With AF as calculated in paragraph 2.2.3, AFc.ch as calculated in paragraph 2.2.1 and ACT as calculated here.

2.3 kBP correction factor

This correction coefficient accounts for tube bundle bypass. It depends on the number of sealing strips that are used in the heat exchanger.

An abacus given by Bell is also given for the calculation but different parameters must 1st be calculated.

2.3.1 Number of sealing strips

Sealing strips come by pairs. They are generally in between 1 to 4 pairs, the number of pairs is noted NDL.

2.3.2 Bundle bypass area ABP

ABP = (DC - DCCF)*B

DC = Shell diameter (m)

DCCF = tube bundle diameter (from most external tubes)

(m)

B = Baffle spacing (m)

2.3.3 Ratio of bundle bypass area to cross flow area

FBP = ABP / ACT = [(DC-DCCF)*B]/ACT

With :

DC = Shell diameter (m)

DCCF = tube bundle diameter (from most external tubes)

(m)

ACT as calculated here

2.3.4 Number of tube rows crossed between baffle tips in one baffle section

This value depends on the tube layout used.

- 90° layout : NCT = (Dc-2h)/P

- 45° layout : NCT = (Dc-2h)/(P√2/2)

- 30° layout : NCT = (Dc-2h)/(P√3/2)

With :

DC = Shell diameter (m)

P = tube layout pitch (m)

h = baffle cut (m)

2.3.5 Calculation of kBP

kBP is determined according to the following abacus by calculating the ratios NDL/NCT as well as the Reynolds.

2.4 kRE correction factor for laminar flow

In case the flow on the shell side is laminar, the dynamic of the fluid changes completely and an additional correction coefficient must be applied.

kRe = 1 if Re < 20 or Re > 100, in this case no

need to go through the calculation procedure given below.

2.4.1 Calculation of the baffles number

The number of baffle can be calculated by :

Nch = L/B - 1

With

L = tube length (m)

B = Baffle spacing (m)

2.4.2 Calculation of the number of tube rows in baffle window

This value depends on the tube layout used.

- 90° layout : NOF = [h-(Dc-DCCF)/2]/P

- 45° layout : NOF = [h-(Dc-DCCF)/2]/(P√2/2)

- 30° layout : NOF = [h-(Dc-DCCF)/2]/(P√3/2)

With :

DC = Shell diameter (m)

DCCF = tube bundle diameter (from most external tubes)

(m)

P = tube layout pitch (m)

h = baffle cut (m)

2.4.3 Number of tube rows crossed between baffles

NCT + NOF

2.4.4 Calculation of kRE

kRE is calculated thanks to 2 abacus. The 1st abacus allows to get an intermediary coefficient k*RE and the second abacus, using k*RE, allows to calculate kRE.

3. Calculation of the heat transfer coefficient on the shell side of a shell tube heat exchanger

The coefficient calculated above can be used to calculate the heat transfer coefficient the following way :