NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Pump cavitation

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. Definition : what is pump cavitation ? |

| 2. How to fix pump cavitation : calculation |

| 3. Consequences : what are the

effects of pump cavitation |

1. What is pump cavitation ?

The phenomena of pump cavitation is due to the vaporisation of the liquid pumped at the entrance of the pump impeller. Bubbles formed then collapse within the impeller when the pressure goes up again. The quick collapse of the bubbles translates in high forces that can damage the pump impeller.

Cavitation is very harmful for pumps.

2. How to fix pump cavitation : calculation

Cavitation will happen if the pressure at impeller entry is below the saturation pressure of the liquid sucked. Static pressure decreases within the pump suction due to the acceleration of the fluid at the suction and pressure can go below the saturation pressure of the liquid.

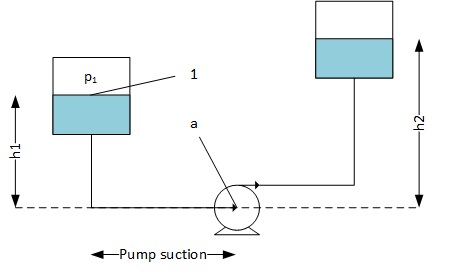

Figure 1 : Pump cavitation - decrease of pressure at pump suction

Cavitation condition : Psuction - NPSH < Psat

Non Cavitation condition : Psuction - NPSH > Psat + margin

The NPSH

is given by the pump manufacturer.

In practice, a margin must be included in the design to

account for process variations (temperature...), it is to be

determined by the engineer according to what is acceptable for the

case studied (consider different liquid pressure, for example,

which can have as effect to change the vapor pressure of the liquid and

thus the pressure at which cavitation can appear), according to

the calculation codes applicable, or experience - some supplier,

if no other value is specified, will consider 0.5 m of margin.

The suction pressure is calculated by summing the pressure in

the vessel in which the liquid is pumped with the static

pressure of the liquid in the vessel minus the pressure drop due

to the suction line. It is therefore necessary to ensure that

there is sufficient pressure at the pump suction in order to

avoid cavitation.

Psuction = P1 + h1*spgr/10.2 - ΔPf

Note : conversion from bar to m of liquid : ΔP = H*spgr/10.2

- ΔP in bar

- H in m

- spgr in kg/m3

Figure 2 : Pump circuit

3. Consequences : what are the effects of pump cavitation

Cavitation in pumps has the following effects

- Possible reduction in pump capacity due to the vaporization,

this drop in performance can be translated by drop of head at same

flowrate or a change in the efficiency of the pump

- Noise

- Vibrations

- Wear of impeller and pump housing due to the collapse of the

bubbles and the pressure associated. It can decrease pump

performance and lead to mechanical failure of the pump. The

elements impacted by cavitation take a very specific "pitted"

aspect.

Source