NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Control valves for 2 phases flow

Calculation of Cv and mass flow through a control valve operating in 2 phases flow

Follow us on Twitter ![]()

Question, remark ? Contact us at powder.process@protonmail.com

1. Cv and Kv definition

1. Cv and Kv definition

What is the flow coefficient Cv and Kv - calculation of flow through a valve - SI units

2. Calculation of Cv and flow through a valve - Case of 2

phases flow - metric units

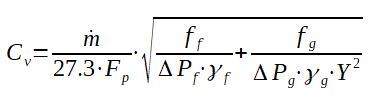

What is the Cv required for a valve in 2 phases flow service ?

When a valve is operated in a bi-phasic flow at the

valve inlet, the Cv required for a given mass flow rate can be

estimated thanks to the following formula [Masoneilan] :

With

m=Flow rate (kg/h)

Fp = piping

geometry factor (reducer correction), it is = 1 if the valve

size is equal to the pipe size

Cv=valve flow coefficient (GPM)

ff = weight fraction of liquid in 2 phases flow (-)

fg = weight fraction of gas in 2 phases flow (-)

ΔPf = pressure drop of liquid phase (bar)

ΔPg = pressure drop of gas phase (bar)

γf =mass density of the liquid phase at inlet conditions

(kg/m3)

γg =mass density of the gas phase at inlet conditions

(kg/m3)

Y = expansion factor = 1-x/(3*Fk*xT)

- x = pressure drop ratio = ΔP/P1 (-)

- P1 = upstream pressure (bar abs)

- Fk = ratio of specific heat factors = k/1.40

- k = gas specific heat ratio

- xT = pressure drop ratio factor (this value is supplied by the constructor of the valve in product brochure). Note the value of xT can be taken as such only if the valve is used without reducers ; if used with reducers it should be corrected (not detailed in this page)

How to calculate ΔPf and ΔPg ?

ΔPf=FL2*(P1-FF*Pv)

ΔPg = Fk*xT*P1

With

ΔPf = pressure drop of liquid phase (bar)

FL = critical flow factor (given by the valve

manufacturer)

P1 = upstream pressure (bar abs)

FF = liquid critical pressure factor =

0.96-0.28*(Pv/Pc)0.5

Pv = vapor pressure of liquid a flowing temperature (bar

abs)

Pc = pressure at thermodynamic critical point (bar abs)

Fk = ratio of specific heat factors = k/1.40

k = gas specific heat ratio

xT = pressure drop ratio factor