NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Pressure Safety Valve Basic Design guide - Low pressure

venting

Pressure Relief Valve sizing for atmospheric, low pressure tanks (pressure / vacuum)

1. Introduction and warning

2. Safety valve sizing - low pressure service

1. Introduction and warning

This design guide aims the reader at understanding the basic concepts behind the design and sizing of pressure relief valves for low pressure venting but not at designing a valve for operational purposes. It is based on published sources but should not be considered for the detail design and selection / ordering of a pressure safety valve. Indeed, pressure safety valves are of utmost importance for the safety of the process, as they are most often the last resort to avoid an explosion, their design must therefore be done only by reputable companies. Only after having clearly defined the application, the position of the valve...etc... with the valve supplier, can he advise properly the plant operator and finalize the design of the valve.2. Safety valve sizing - low pressure service

2.1 Theory

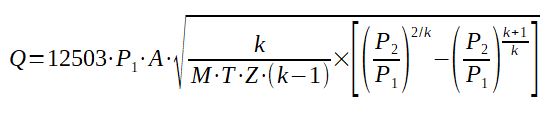

For low pressure tanks, the following formula can be used (WARNING - This formula is not valid for gas at pressure > 1.034 barg and not valid for liquid, please refer to this page) :

Q = theoretical flow through the valve in Nm3/h

T = absolute temperature at inlet in K

M = molecular weight of gas

Z = compressibility factor at inlet conditions

The actual flow through the valve is lower than the theoretical flow. This non ideality is represented thanks to a coefficient of discharge of the valve, K.

K = Actual flow / Theoretical flow

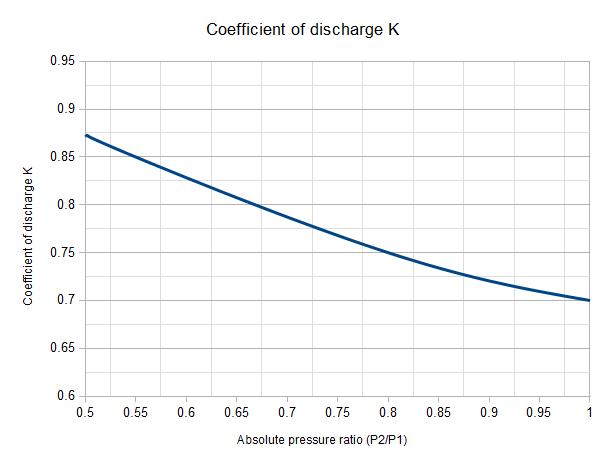

The coefficient K is defined by the manufacturer. API 2000

5th edition is giving an example :

Figure 1 : Coefficient of

discharge K of low pressure / vacuum safety valves

Depending on the technology of the valve chosen, either direct operated (weighed pallet valve) or pilot operated, an overpressure is required to reach the maximum flow. API 2000 is giving the following graph to estimate the overpressure per type of valve. It is very important to consider, especially for direct acting valve that will only reach their rated capacity at 100% overpressure. The tank protected must therefore be able to hold this overpressure.

Figure 2 : Capacity / Overpressure

characteristics of low pressure vents

2.2 Practice

This kind of valve's flow is highly dependent on the design of the valve and actual overpressure allowable , it is recommended to refer to the manufacturer's flow table for a given valve, done according to API 2000. An example is give below :

Once the valve is selected for the flow

required for your application, then the actual flow considering the

overpressure must be determined. Another table with a corrective

coefficient is then given. If the overpressure acceptable is not the

one of table 1, then the flow is to be corrected.