NEWS : Process Engineer's Tools is moving to a new address, www.MyEngineeringTools.com, click here to discover the site |

Valves and fittings pressure drop K coefficient (laminar)

Question or remark ? Please contact us at powder.process@protonmail.com

1. Introduction

2. Pressure drop calculation

1. Definition

2. Pressure drop calculation

K coefficient can reasonably be used until Re=500, below, specific coefficients should be used.

2.1 Kittredge and Rowley

The data of Kittredge and Rowley are reported in many books. They have tabulated the frictional loss coefficients for different fittings and valves and different Reynolds. If the flow is found to be laminar they should be used in pressure calculation instead of the coefficients calculated for turbulent flow

Table 1 : K coefficient for

calculation of pressure drop through valves and fittings in

laminar flow according to Kittredge and Rowley

2.2 Hooper

As an alternative, the method of Hopper can be used. As most of the data obtained in laminar flow, results are approximate.

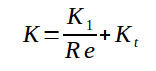

The frictional loss coefficient can be calculated from the value in turbulent flow and coefficients to account for laminar flow :

- K1 = pressure drop coefficient for Re=1

- Kt = coefficient in turbulent flow

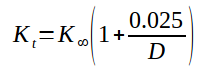

If unknown, Kt can be calculated with the following formula where K∞ is the coefficient in turbulent flow for a very large diameter

Coefficient K1 can be calculated thanks to the following table.

Table 2 : K1 coefficient for

calculation of pressure drop through valves and fittings in

laminar flow with the approximation of Hooper