Hammer Mills : an overview

What is a hammer mill ?

How does a hammer mill work ?

Follow us on Twitter ![]()

Question, remark ? Contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. What is a

hammer mill ? |

| 2. Hammer mill

working principle |

| 3. Hammer mills

design |

| 4. Industrial hammer mills |

1. What is a hammer mill ?

The hammer mill design is very robust and is used in many milling applications, from grain milling to heavy duty requirements such as rock crushing or waste grinding. Hammer mills are a very common comminution equipment found all across process industries.

Hammer mills are part of the impact mill family, which means that the milling effect is obtained thanks to the speed at which particles are impacted, here, by one or several rotors.

2. Hammer mill working principle

How does a hammer mill work ?

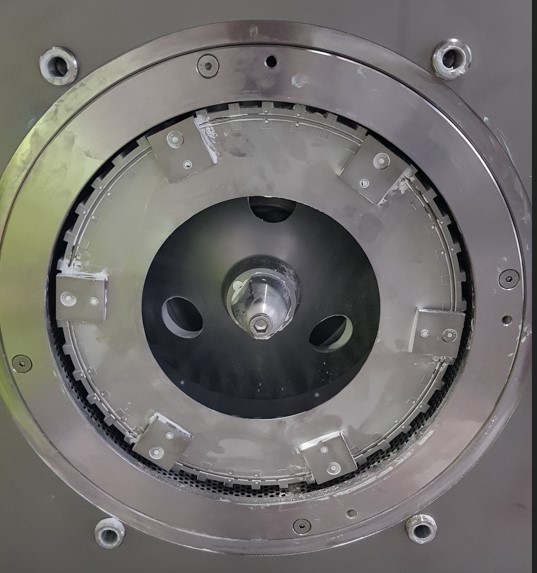

The working principle of a hammer mill is to have a rotor, equipped with hammers (thick plates) rotating at high speed within a casing, that may be equipped with a grid, and that reduces the size of the feed material by impacting them.

Hammer mills are designed with a shaft on which are mounted several "hammers" which have most of the time the shape of thick plates. The shaft is rotating within a casing, and at the outlet of the mill is mounted a screen whose size will determine which particles are fine enough to leave the mill. The mill can be fed and discharged by gravity when using the mill as a crusher, while the milled products may actually be directly pneumatically conveyed, using the high amount of air moved by the mill, for fine milling applications.

Figure 1 : Hammer mill diagram with components (gravity discharge)

The fineness of the powder produced by the mill is a function of the mill speed, screen size, and feed rate. In general the screen size must be chosen significantly larger than the required product fineness, the primary function of the grate is to retain in the mill large particles that are then impacted by the hammers and then will become much smaller than the screen holes. The resulting particle size distribution will be relatively broad in hammer mills [Perry].

3. Hammer mills design

3.1 Hammers

The number of hammers in a mill is variable, depending on the fineness looked after as well as the mill capacity, however, in general the higher the number of hammer, the finer will be the product, but the capacity will also decrease.

The mill can be more or less wide depending on the number of rows of hammers mounted on the shaft. Each row of hammer is separated from the other with a spacer plate.

The length of the hammers can also be adjusted. If the hammer length is increased, coming closer to the screen, the resulting product will be finer, however the capacity will decrease. Shorter hammers will produce a coarser product but will authorize a higher capacity.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1.

Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time optimization

4. Batch / continuous mixing

comparison

5. Energy Savings

3.2 Shaft speed

The 2nd key design and operational aspect for a hammer mill is the rotation speed. As the milling principle is based on the energy of the impact, the higher the speed, the finer the product can be expected as the particles will hit the hammer at high speed, but also be sent against each other or against the screen at high speed.

One must however be careful not to increase the speed without specific reason and care, as a high speed is increasing the energy input, temperature increase, and mechanical fatigue of the whole mill which can lead to intensified maintenance needs. Very high speed rotation will be reserved to soft materials for fine grinding while lower speed will be used to perform a crushing of larger / harder products.

3.3 Screen size (grating discharge)

The screen size will help to control the particle size of the milled product by preventing that too large particles leave the mill before being comminuted. Reducing the screen size will thus help to reduce particle size distribution of the final product but it will come to the expense of the mill capacity.3.4 Drive

A hammer mill drive must be equipped with a frequency converter in order to be able to control the speed and thus adjust the capacity and resulting fineness of the materials.

3.5 Product feed

The feed to the mill must be controlled (at least roughly) by a dosing equipment such as a vibrating tube, a screw conveyor, or an airlock rotary valve. If the mill is wide, with several hammer rows separated by spacer plates, the feeding system must allow a good repartition of the feed all along the mill. As the mill will be requiring a lot of air, it is also key to have an air inlet.

3.6 Product discharge

If the mill is used as a crusher, which means that the particle size diameter of the finished product is quite coarse (>> 1 mm), then the mill can be discharged by gravity. However, for finer target sizes, requiring very high speed and thus moving a lot of air, the final product can be transferred pneumatically. In any case, it is necessary to consider the air requirements of the mill and foresee filters at air suction, and at air discharge (in the discharge hopper for gravity discharge, or in the receiving hopper after pneumatic conveying).

The air management in a hammer mill must be carefully studied, [Liu] mentions that if the air flow is incorrect a mill can lose up to 50% of its capacity. The following rule of thumb is given :

- 260 m3/h to 775 m3/h for 1 m2 of screen area

- 1350 m3/h to 2050 m3/h for 1 t/h of feed

These are only rule of thumbs, assistance from a mill supplied is mandatory for detail design.

3.7 Safety

Hammer mill have rotating elements, the hammers, at very high speed (up to 120 m/s), thus the ingress of foreign bodies such as metal particles can have severe mechanical and safety consequences (dust explosions). The mill must therefore be protected by sieving the feed and positioning a strong magnet or even a metal detector at the inlet. The risk of dust explosion must also be addressed by having a mill resistant to explosion, or by using protections (explosion panels, suppression systems...).

3.8 Similar design

Other design are similar in some aspects to Hammer Mills :

- Pin mills (without a screen)

- Universal Mills : mills for which the hammers can be changed for other types of beaters

4. Industrial hammer mills

What is a hammer mill used for ?

Hammer

mills are typically used in large industrial processes

requiring a high throughput while guaranteeing relatively fine

product. Some robust design can be found in mining industries,

while other suppliers have specialized in hammer mills for

animal feed (animal nutrition, aqua feed, pet food).

Large

hammer mills can reach up to 20-50 t/h depending on the

expected granulometry (more fine, less capacity ; coarser,

larger capacity). Materials having a size up to 60 mm can be

grounded to ~1 mm, while, if the feed is already finer (10

mm), hammer mills can reach sizes less than 500 microns.

Hammer mills suppliers :

- Stolz

hammermills

- Hosokawa

- Buhler

- Prater

Industries

PowderProcess.net has no relation with those companies, only given here as indication for the reader looking for a supplier

Source[Perry] Perry's Chemical Enginneer's Handbook, 8th edition, 21-59