VFFS Vertical Form Fill and Seal machines (Powder filling systems)

Overview and principle of operation of Vertical Form Fill and Seal machines

Question or remark ? Please contact us at admin@powderprocess.net

| Section summary |

|---|

| 1. Introduction to

VFFS machines |

| 2. Working

principle : the filling sequence |

| 3. VFFS packaging machines applications |

| 4. VFFS machine manufacturers |

1. Introduction to VFFS machines

What is a Vertical Form Fill Seal Machine ?

Vertical filling machine are a popular design found all across industries filling materials in small packaging. It is used in chemicals (detergents) and especially food industries to fill any kind of powders, and sometimes some more granular materials (candies).

VFFS machines are automated to reach filling capacities relevant for industries and thus equipped with multiple components that must be activated in a coordinated way in order to have a proper filling. As this type of machine is quite widespread in industries, engineers wishing to know more about VFFS machine will find in this page information regarding the filling sequence and the different design of fillers available in the market. The information focuses on powder filling.

2. Working principle : the filling sequence

How do Vertical Form Fill Seal (VFFS) Packaging Machines Work?

2.1 VFFS machine design

A vertical packaging machine such as the VFFS is made of the following sections :

- Dosing system

- Forming area

- Film feeding and alignment

- Sealing and cutting

The following Vertical Form Fill Seal diagram shows the different components of the machine and its and principle of operation :

Figure 1 : Filling steps and

components of a typical VFFS machine

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry

Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4.

Batch / continuous mixing comparison

5. Energy Savings

2.2 Filling sequence

STEP 1 : Packaging material unwinding

The packaging material, for example some aluminium foil, plastic laminate or even paper is delivered in rolls. The material must therefore be rolled out, or "unwinded" in order to be used. The film is pulled out and tensionned thanks to several rollers and a weighed pivot arm in order to be ready for a good forming. The unwinder is positioned at the back of the machine.

STEP 2 : Forming of the pouch

The material is fed flat and tensioned to the filling tube, however the shape of the pouch must be given to the packaging material in order to be able to perform the filling. It is done thanks to a specific part of the forming tube, called forming shoulder or forming collar. The packaging material is then twisted around the forming tube and pulled all along the tube, which enables the next stages of the filling process.

Just after forming, some pull down belts are installed in order

to move the film (in some design, others use the sealing jaws to

pull the film).

STEP 3 : Vertical sealing

Once the packaging material is well wrapped around the forming tube, then a 1st sealing, on the side, can be done. The forming collar and the width of the packaging reel must be such that there is an overlap when wrapping the material around the tube. A couple of sealing jaws, or sealing bars, is then used to press against each other the 2 parts of the overlapping material and weld them, often thanks to heating, to create a side seal. To be noted that there are different kind (shapes) of seals.

Figure 2 : Example of a VFFS machine, showing the front of the machine with forming, Filling, sealing steps

STEP 4 : Bottom sealing

The product cannot yet be fed to the filling tube as there is no bottom seal to the pouch. It is done by another couple of sealing bars that are also welding the material through pressure and heating.

The material is then pulled down by a length corresponding to the desired pouch length.

STEP 5 : Product filling

The dosing system positioned about the forming tube can finally be run in order to dose the amount of product to dose. The material falling down through the forming tube and inside the open pouch being manufactured.

The product filling technology can be of different types :

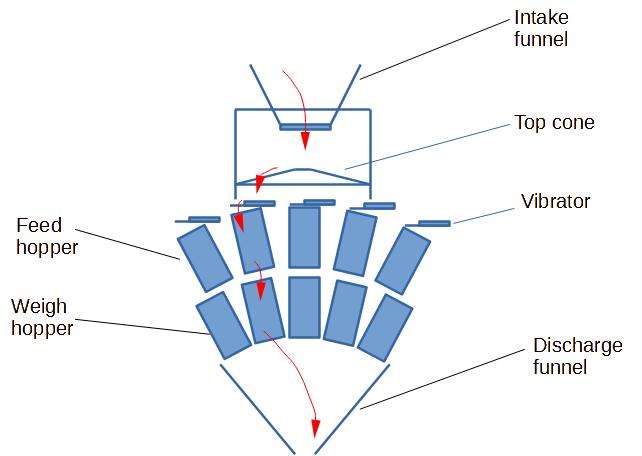

- Multihead weigher : a specific dosing system is installed above the filling machine and will deliver the exact amount of pre-weighed material when the filling machine is ready to receive it. The weighing can be done thanks to linear scale (relatively slow) and combination scale (very quick and precise but will be limited in amount to weight). It is particularly adapted to granular products, for example nuts or kibbles found in petfood. It can also allow co-dosing and mixing (will dose for instance 2 components separately and will drop them at the same time to the packaging)

- Auger filling : this dosing system is using a screw vertically positioned inside a hopper in order to dose the required amount of material to the bag. It is a good system for powders as it is closed and will therefore avoid to release dust. Although it is a volumetric system, the use of servomotors to activate very precisely the screw ensures a good filling accuracy. Such Auger system can allow to have several lanes in a single machine and thus increase the capacity.

- Volumetric cup dosing : it is a simple solution with material flowing by gravity inside cups of defined volume, but reliable only with powders which are very free flowing and not changing in density ; to change the amount dose it is indeed necessary to change the cups which is much less flexible than Auger filling for instance where the number of turns of the screw can be adusted

- Liquid dosing : it is important to note that VFFS can be adapted to filling liquid as well.

STEP 6 : Top sealing

Once the dosing of product has been done, then the same sealing jaws that performed the bottom seal are activated again to, this time, create the top seal and close the pouch.

Note that for some design, the sealing jaws can also have a vertical movement up and down which allows to pull the film all along the machine and unroll it from the reel positioned on the unwinder.

STEP 7 : Cutting and discharge

After closing the pouch, it is then cut and falls down to a collection system, typically a belt conveyor that brings the pouch to the next packaging step (putting in a box...)

2.3 Intermittent or continuous filling

For the simpler VFFS packaging machines, the steps above are done sequentially. However, faster design allowing a continuous process, are also available from some suppliers.

Depending on the technology, manufacturers report filling speed of 30 to 80 pouch per minute for intermittent VFFS packaging machines and 100-200 or even up to 300 pouch per minute for continuous vertical form fill and seal machines.

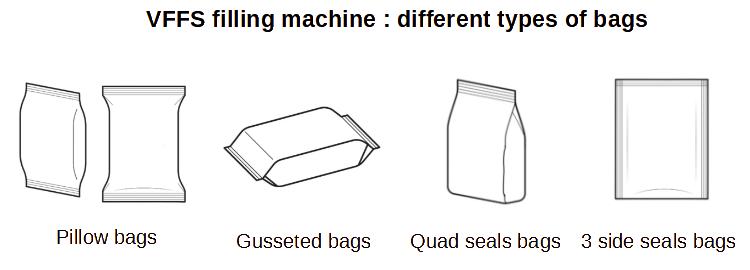

3. Types of bags

VFFS machines can be adapted to fill different kinds of bags. Typical bag shapes for VFFS packaging machines are shown below :

4. VFFS packaging machines applications

VFFS (Vertical Form Fill Seal) packaging machines are widely used in a variety of industries to package various products. In the food industry, VFFS machines are used to package a wide range of products including snacks, bakery items, and fresh produce. In the pharmaceutical industry, VFFS machines are used to package pills, tablets, and other medications. Other industries that use VFFS machines include pet food, household products, and personal care products. The versatility and flexibility of VFFS machines make them suitable for packaging products of different shapes, sizes, and consistencies. With the ability to customize the packaging material, size, and shape, VFFS machines can be adapted to meet the specific needs of each product and industry.

5. VFFS machine manufacturers

Considering to buy a VFFS packaging machine ?

There are many manufacturers proposing vertical form fill seal machine for sale, however the quality of the delivery can be quite variable as these machines, especially the fast ones, require a high precision of Engineering and assembly to work reliably in factories. In doubt, contact 4-5 suppliers and start by discussing with them, asking technical questions for example using the information of this article to understand their technical levels. If convincing, the references of the manufacturer should be ask to make sure they have already experience in the application targeted.

Some companies that can be consulted for details and sales : http://www.petra-pack.com/

(Note that this company has no link with PowderProcess.net)